Organic photoelectric detector based on mixed hole transport layer and preparation method of organic photoelectric detector

A technology of hole transport layer and photodetector, applied in organic semiconductor devices, photovoltaic power generation, electric solid state devices, etc. Problems such as carrier recombination probability, to avoid carrier recombination, improve hole mobility, and reduce dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

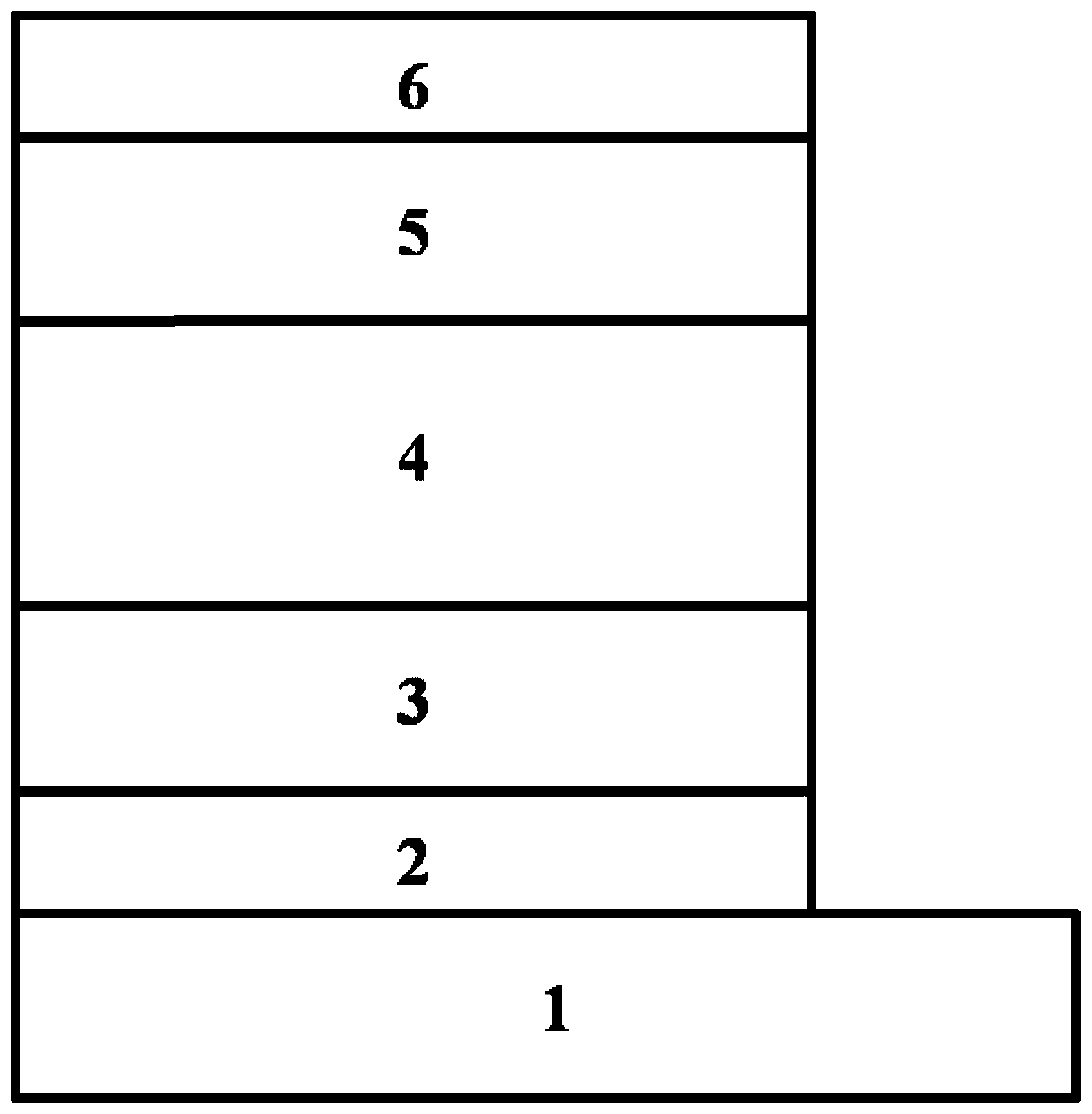

[0034] Clean the substrate composed of a transparent substrate and a transparent conductive cathode ITO with a surface roughness less than 1nm, and dry it with nitrogen after cleaning; spin-coat the surface of the transparent conductive cathode ITO to prepare a ZnO solution (5000rpm, 40s), and then thermal anneal Treat (150°C, 15min) to prepare electron transport layer, prepare P3HT:PCBM (1:1, 30mg / mL) photoactive layer (800rpm, 30s) on the electron transport layer, evaporate hole transport layer on the surface of photoactive layer MoO 3 Mix material with chitosan (1:0.03, 15nm); evaporate metal anode Ag (100nm) on the hole transport layer.

[0035] Under standard test conditions: AM 1.5, 100mW / cm 2 , the measured dark current of the device (J d )=3.33×10 -6 A / cm 2 , photocurrent (J ph )=3.35×10 -3 A / cm 2 , specific detection rate (D*)=2.3×10 11 Jones.

Embodiment 2

[0037] Clean the substrate composed of a transparent substrate and a transparent conductive cathode ITO with a surface roughness less than 1nm, and dry it with nitrogen after cleaning; prepare a ZnO solution (5000rpm, 40s) by spin-coating on the surface of the transparent conductive cathode ITO, and heat Annealing treatment (150°C, 15min) to prepare electron transport layer, prepare P3HT: PCBM (1:1, 30mg / mL) photoactive layer (800rpm, 30s) on the electron transport layer, evaporate hole transport layer on the surface of the photoactive layer MoO 3 Mix material with chitosan (1:0.05, 15nm); evaporate metal anode Ag (100nm) on the hole transport layer.

[0038] Under standard test conditions: AM 1.5, 100mW / cm2 , the measured dark current of the device (J d )=1.52×10 -6 A / cm 2 , photocurrent (J ph )=4.25×10 -3 A / cm 2 , specific detection rate (D*)=4.77×10 11 Jones.

Embodiment 3

[0040] Clean the substrate composed of a transparent substrate and a transparent conductive cathode ITO with a surface roughness less than 1nm, and dry it with nitrogen after cleaning; prepare a ZnO solution (5000rpm, 40s) by spin-coating on the surface of the transparent conductive cathode ITO, and heat Annealing treatment (150°C, 15min) to prepare electron transport layer, prepare P3HT: PCBM (1:1, 30mg / mL) photoactive layer (800rpm, 30s) on the electron transport layer, vapor-deposit hole transport on the surface of the photoactive layer Layer MoO 3 Mix material with chitosan (1:0.08, 13nm); evaporate metal anode Ag (100nm) on the hole transport layer.

[0041] Under standard test conditions: AM 1.5, 100mW / cm 2 , the measured dark current of the device (J d )=1.14×10 -6 A / cm 2 , photocurrent (J ph )=6.22×10 -3 A / cm 2 , specific detection rate (D*)=5.56×10 11 Jones.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com