Micro-flow control system and method based on piezoelectric proportional valve

A technology of a control system and a control method, which is applied in the direction of flow control, flow control, and control/regulation system using electric devices, can solve the problems of long-term stable control of micro flow and flexible adjustment in a large range, etc., and achieve stable displacement and thermal stability. The effect of low consumption and wide flow adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention overcomes the deficiencies of the prior art and provides a micro-flow control system and method based on piezoelectric proportional valves, which solves the problem that the current electric propulsion system cannot realize long-term stable control of micro-flow and flexible adjustment in a wide range, and has stable performance , flexible adjustment, and high precision, the method of the present invention will be further explained and described below in conjunction with the accompanying drawings.

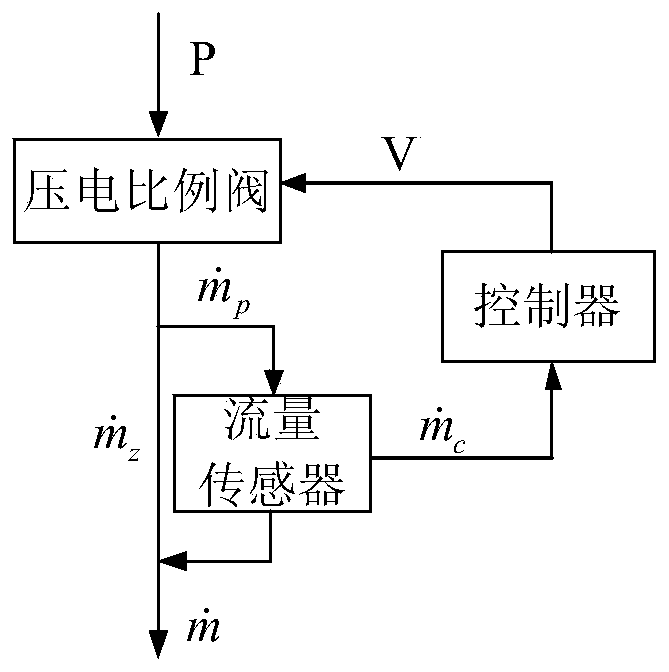

[0029] Such as figure 1 As shown, a micro-flow control system based on a piezoelectric proportional valve of the present invention includes a piezoelectric proportional valve, a flow sensor, and a controller, wherein:

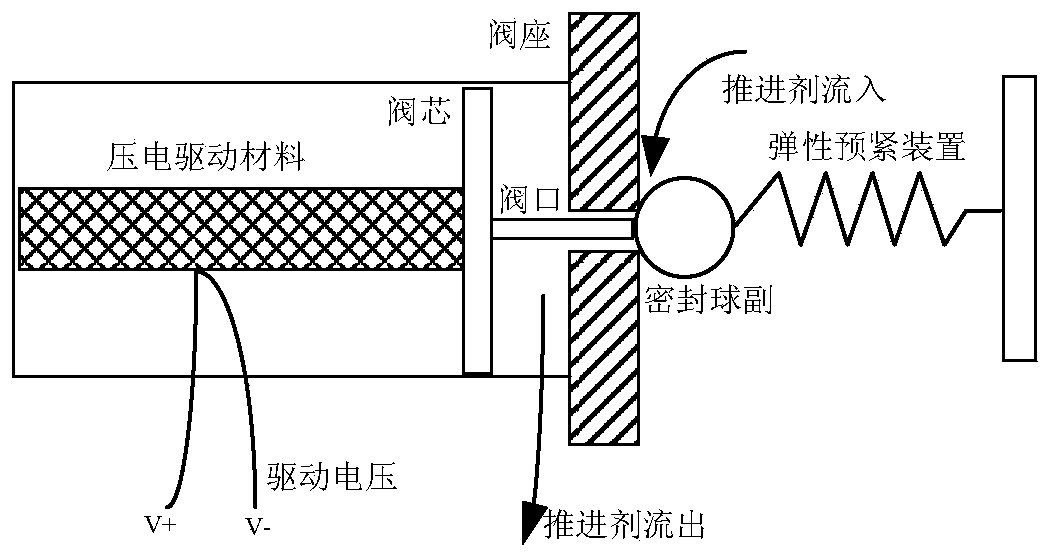

[0030] When the driving voltage is not applied, the valve is in the closed state, and the flow output is zero; after receiving the driving voltage signal output by the controller, the opening degree of the valve is controlled according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com