Concrete pumping full simulation test device and detection method

A concrete pump and simulation test technology, which is applied in the direction of measuring devices, fluid dynamics tests, material inspection products, etc., can solve problems such as high cost, and achieve the effect of simple operation, high degree of automation, simple and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

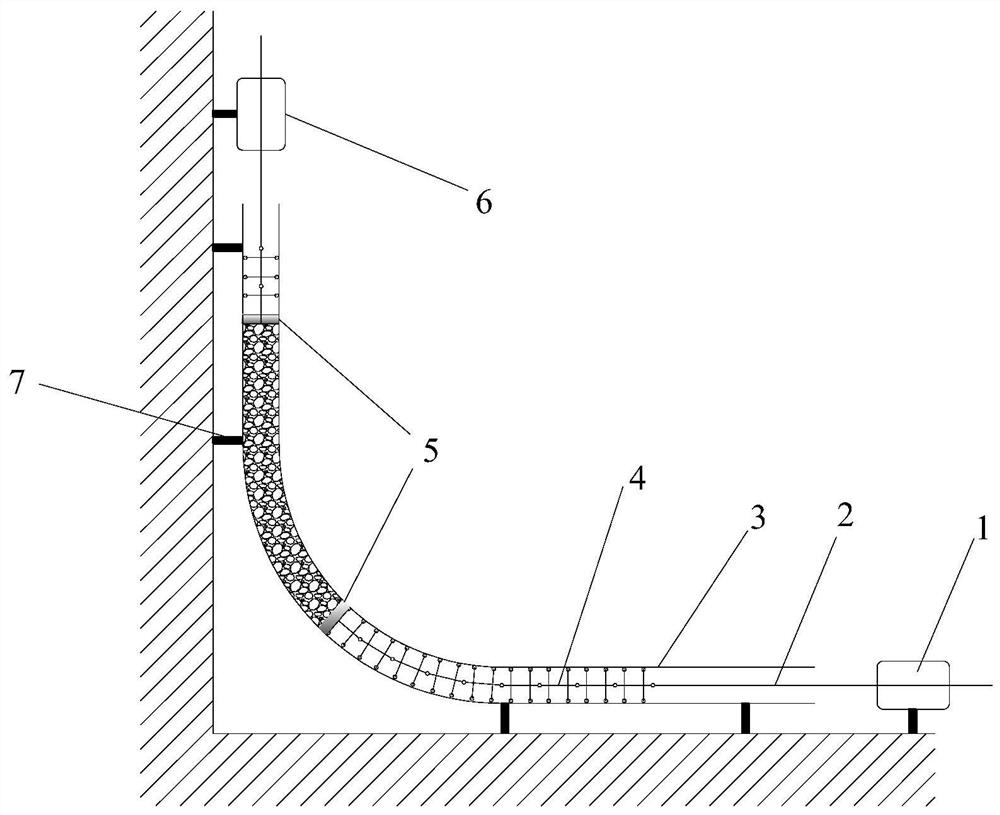

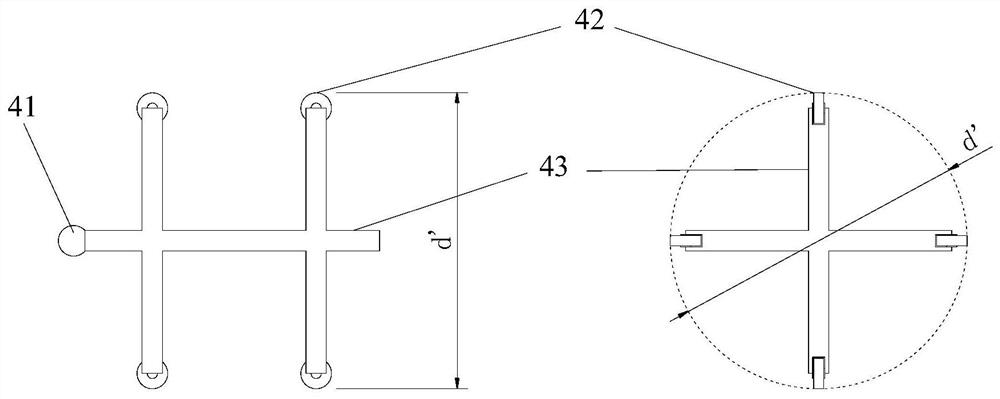

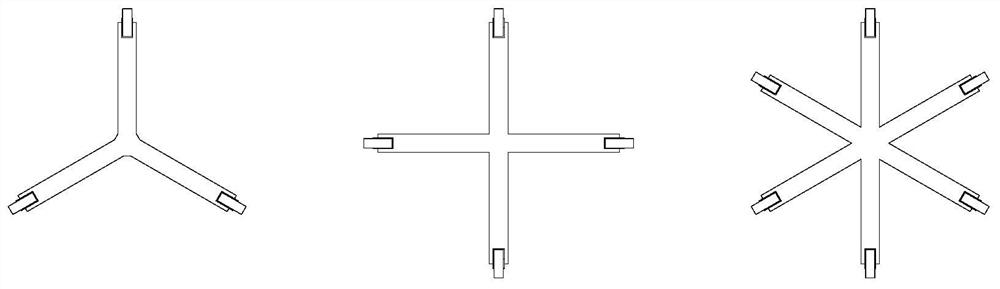

[0040]Combine below Figure 1 to Figure 5 , detailing the structural composition of the concrete pumping whole process simulation test device of the present invention.

[0041] Please refer to Figure 1 to Figure 4 , a concrete pumping full simulation test device, including a plurality of simulation units, the simulation unit includes a curved pipe simulation unit and a straight pipe simulation unit, the simulation unit includes a fixing device 7 fixed on the pump pipe 3 on the base and a power unit, The power devices are power device one 1 and power device two 6 respectively. Two quasi-rigid chains 4 are installed in the pump pipe 3, and one end of the two quasi-rigid chains 4 is close to each other. A concrete sample is arranged between the outer end surfaces of 5, that is to say, the concrete sample is enclosed between two quasi-rigid chains 4, and the free ends of the quasi-rigid chains 4 pass through the rigid straight rod 2 and the external power device respectively. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com