A kind of urban pipeline dredging machine

An urban pipeline and dredging machine technology, applied in the field of urban pipeline dredging machines, can solve the problems of harsh environment, casualties, deaths, etc., and achieve the effects of reducing the risk of operation, improving the effect of dredging, and improving the efficiency of dredging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

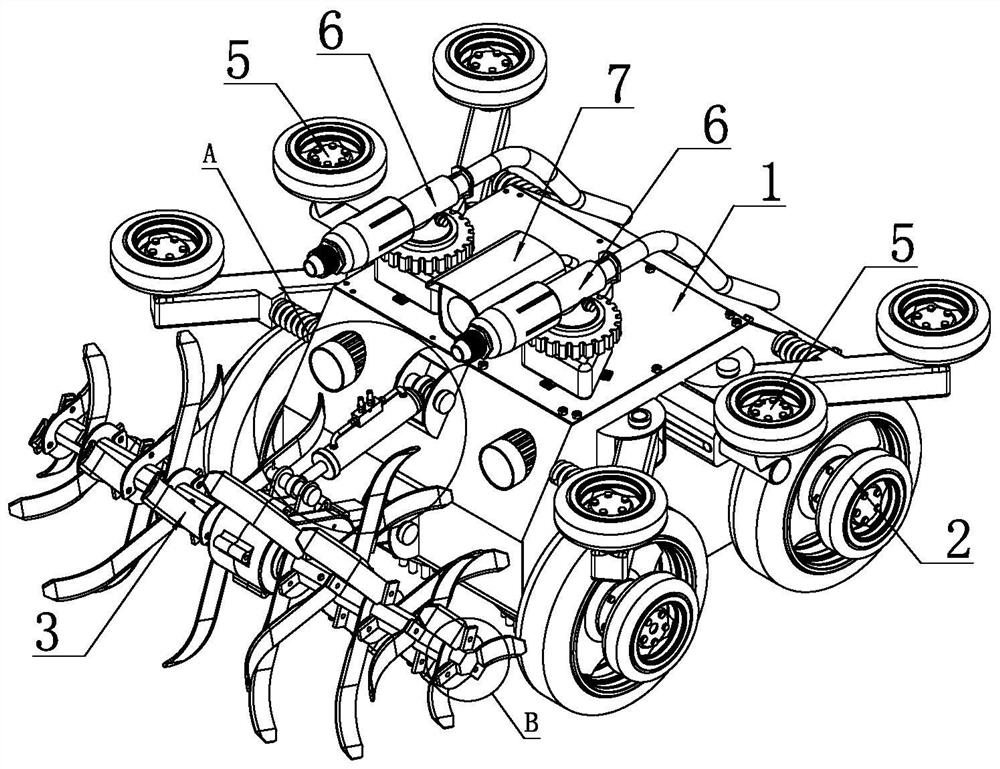

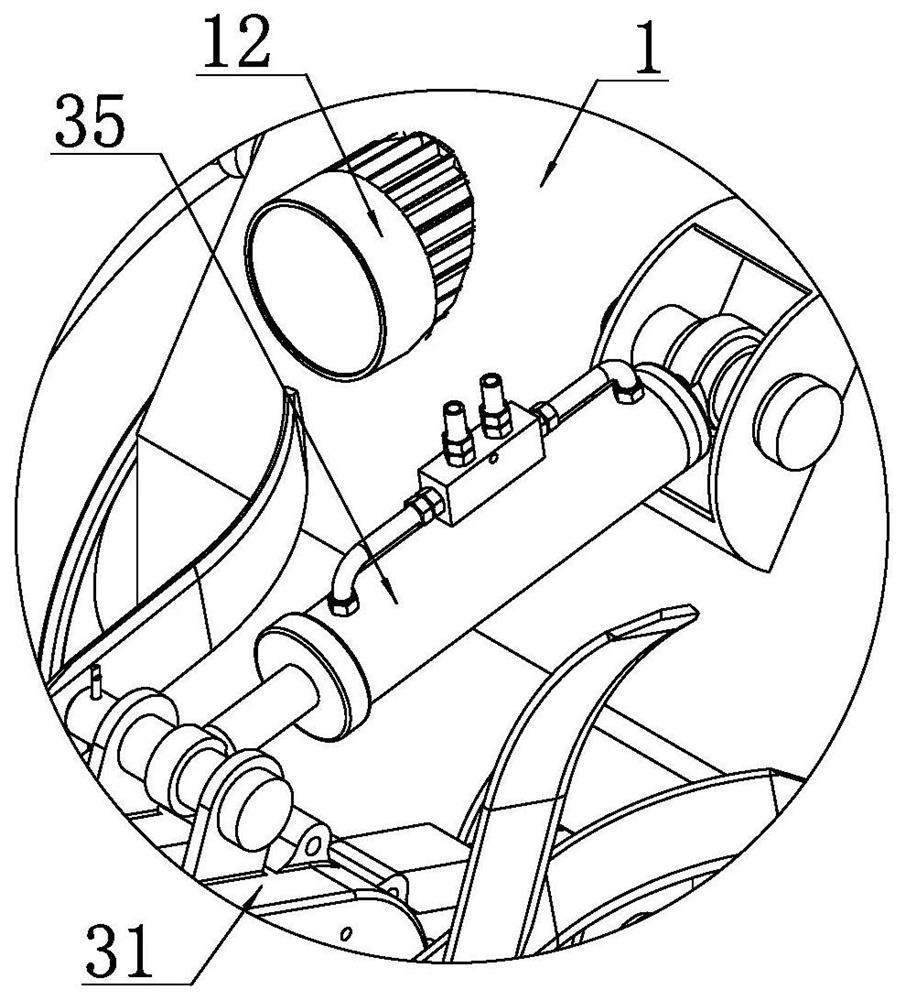

[0043] Such as figure 1 , Figure 4 and Figure 6 As shown, a kind of urban pipeline dredging machine comprises vehicle frame 1, and the left and right sides of described vehicle frame 1 are respectively provided with walking unit 2, and the front end of described vehicle frame 1 is provided with chopping unit 3, and described vehicle frame A cleaning unit 4 is arranged under the vehicle frame 1 , and a control unit, a storage battery and a hydraulic station for providing energy for the traveling unit 2 , the shredding unit 3 and the cleaning unit 4 are arranged in the vehicle frame 1 .

[0044] As a specific implementation, the vehicle frame 1 described in this embodiment is a box structure, including a frame welded by section bars and a cover plate fixedly arranged outside the frame.

[0045] Such as Figure 11 and Figure 12 As shown, the traveling unit 2 includes two main wheels 23, and the two main wheels 23 are respectively rotatably connected to the vehicle frame 1 ...

Embodiment 2

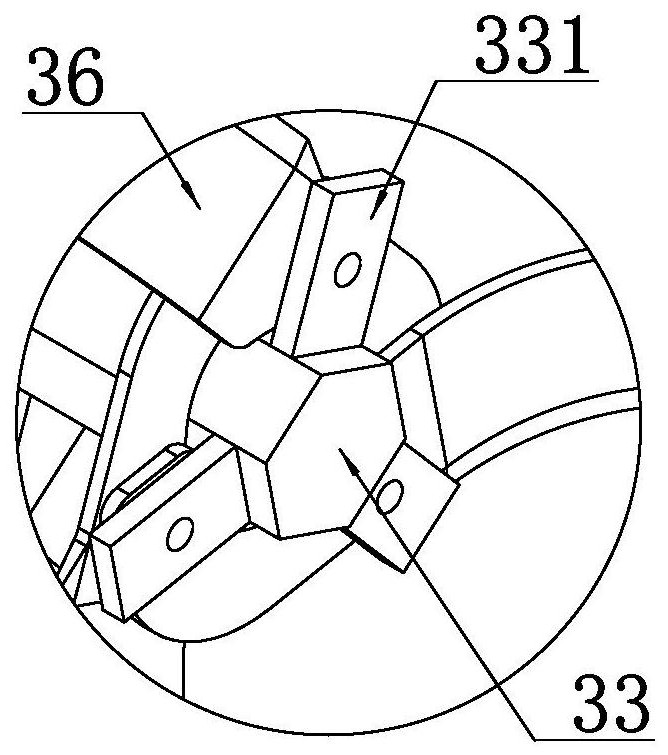

[0063] The bottom plate of the vehicle frame 1 is provided with a driving shaft and two driven shafts, and the driving shaft and the driven shafts are respectively rotatably connected to the bottom plate of the vehicle frame 1 through a bearing assembly. The lower ends of the driving shaft and the driven shaft are fixedly provided with a cleaning disc 41 , and the upper end of the driving shaft is connected with a second motor 44 fixedly installed in the vehicle frame 1 . The driving shaft is located inside the vehicle frame 1 and is provided with a second driving gear 42, and the driven shaft is located inside the vehicle frame 1 and is respectively provided with gears that mesh with the second driving gear 42. The second driven gear 43, and there is no meshing relationship between the two second driven gears 43.

[0064] All the other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com