Laminating mold having rapid cleaning function

A coating and mold technology, applied in the cleaning method of tools, fiber raw material processing, cleaning methods and utensils, etc., can solve the problems of time-consuming and manpower, easy to stick to the back of the printed product, and block the mold mouth. Achieving improved stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

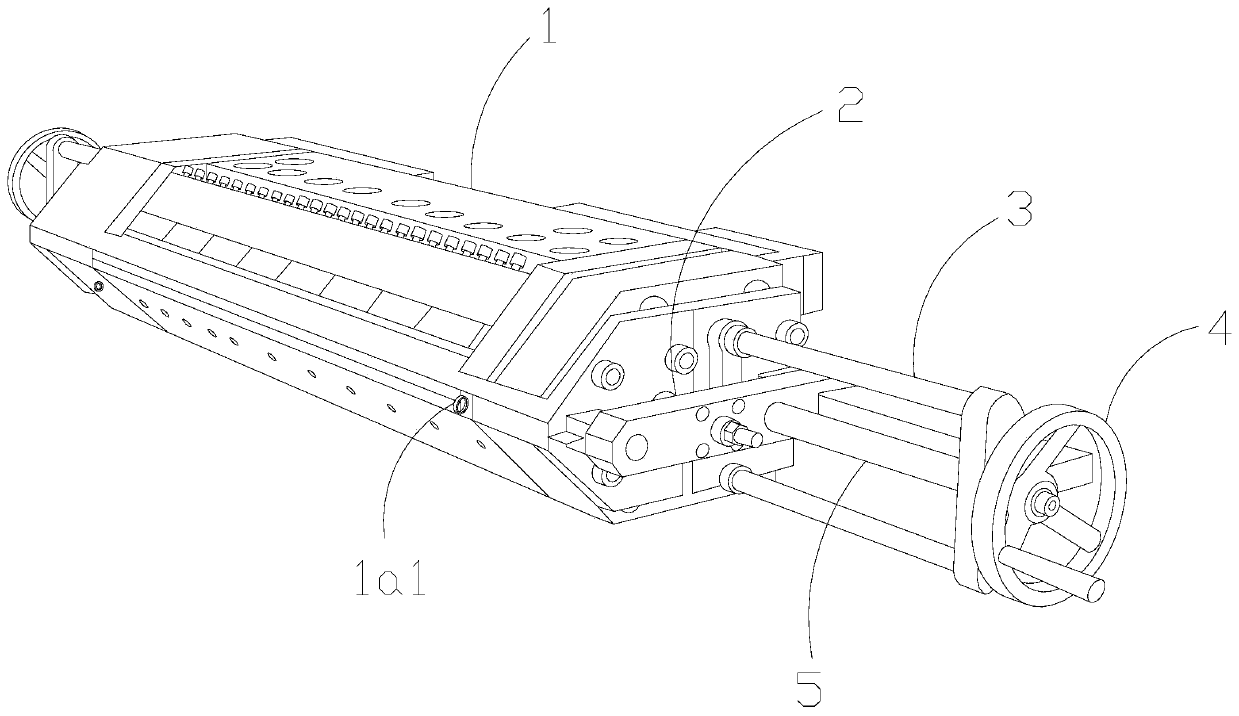

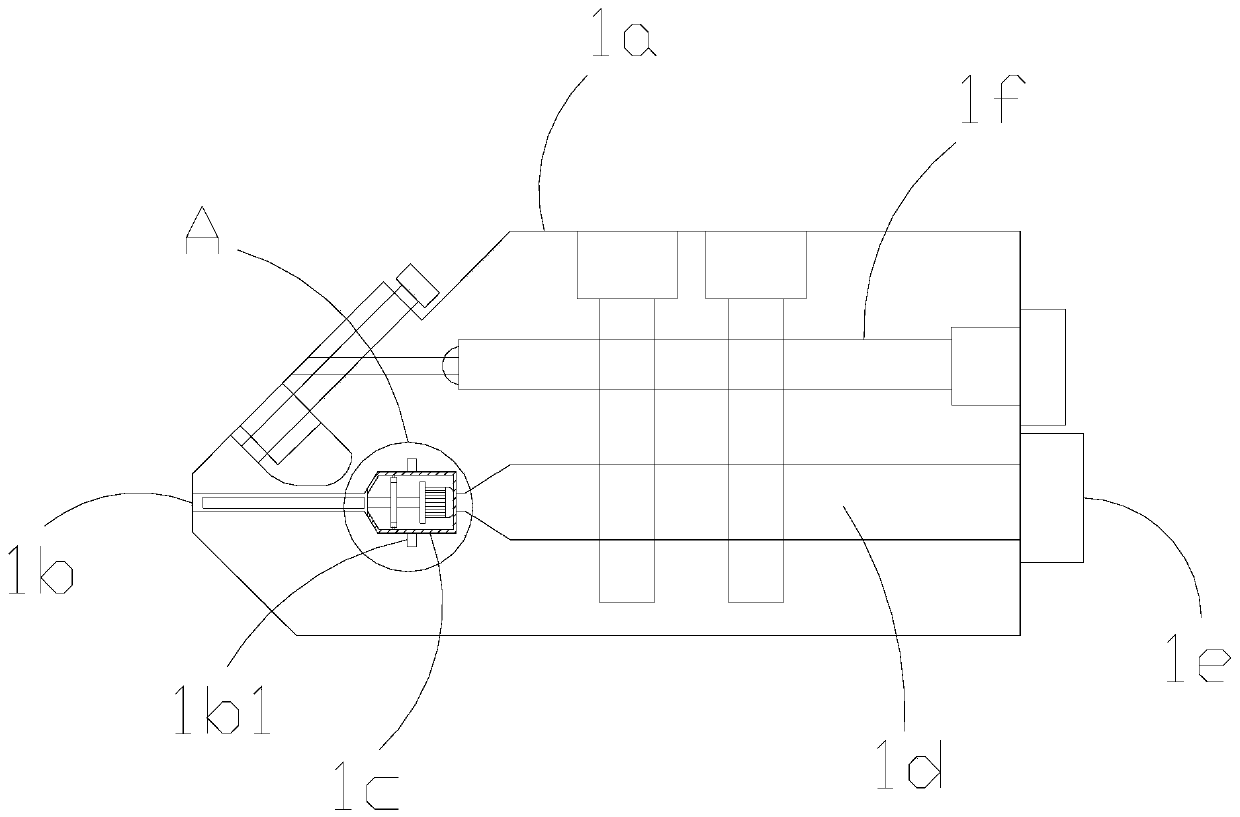

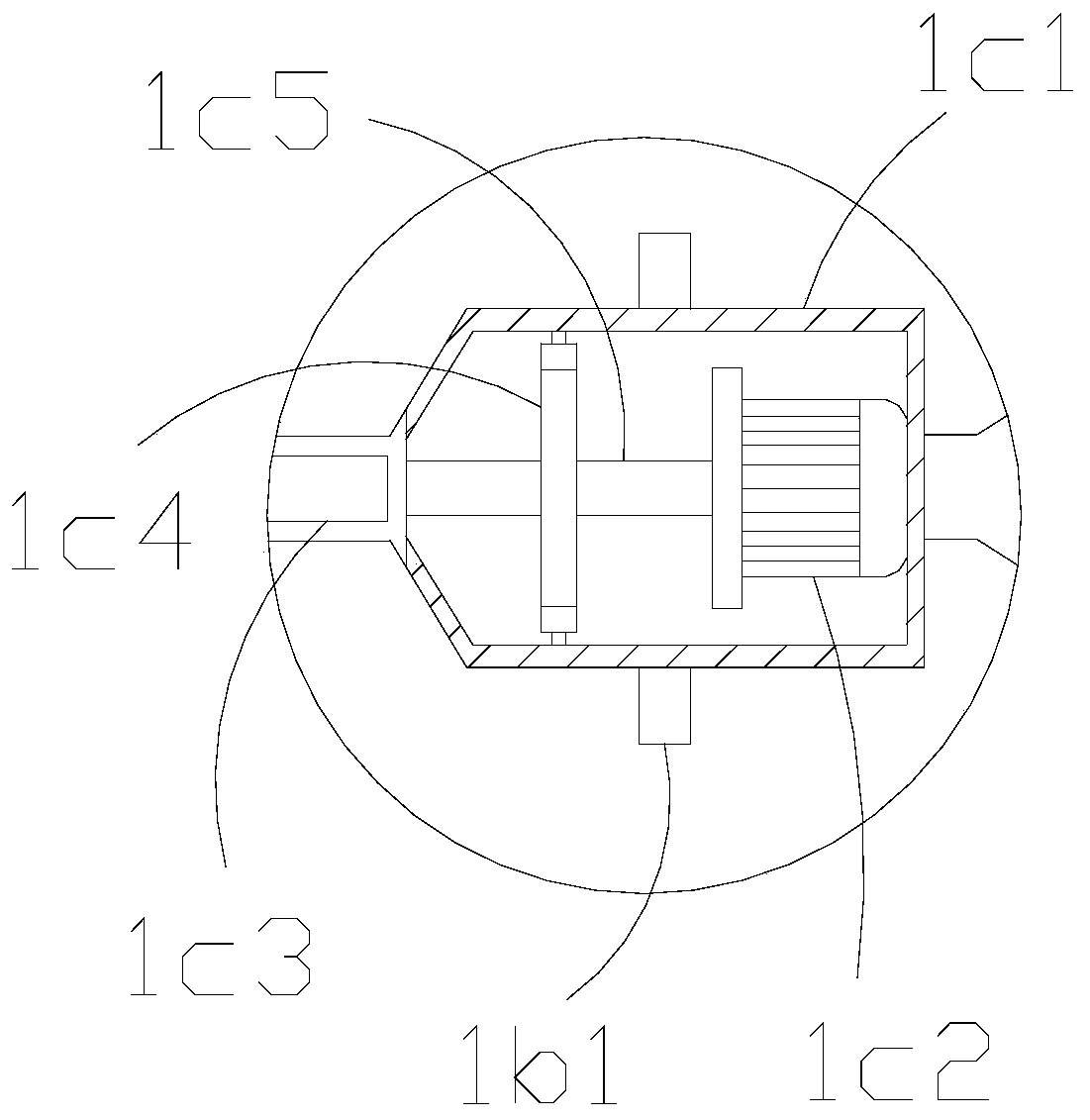

[0028] see Figure 1-Figure 7 , the present invention provides a film coating mold with quick cleaning function, its structure includes a film coating mold 1, a sealing briquetting block 2, a guide frame 3, a guide hand wheel 4, and a transmission screw rod 5, and the guide frame 3 is provided with There is a coating mold 1, the guide frame 3 is flexibly connected with the coating mold 1, the left and right ends of the guide frame 3 are provided with a guide handwheel 4, and the guide frame 3 and the guide handwheel 4 pass through the transmission The screw rod 5 is connected by transmission. The left and right ends of the coating mold 1 are equipped with sealing briquetting blocks 2. The coating mold 1 is composed of a mold body 1a, a coating compression flow channel 1b, a cleaning mechanism 1c, and a die head flow channel. 1d, feed installation flange 1e, heating plate 1f, recovery box 1g, the inside of the mold body 1a is equipped with a heating plate 1f, the mold body 1a i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com