Reaction sputtering system

A sputtering system and reaction technology, applied in the field of reactive sputtering systems, can solve the problems of impure thin film composition, difficult to obtain thin film, inaccurate control of reactive gas partial pressure, etc., and achieve the effect of improving stability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

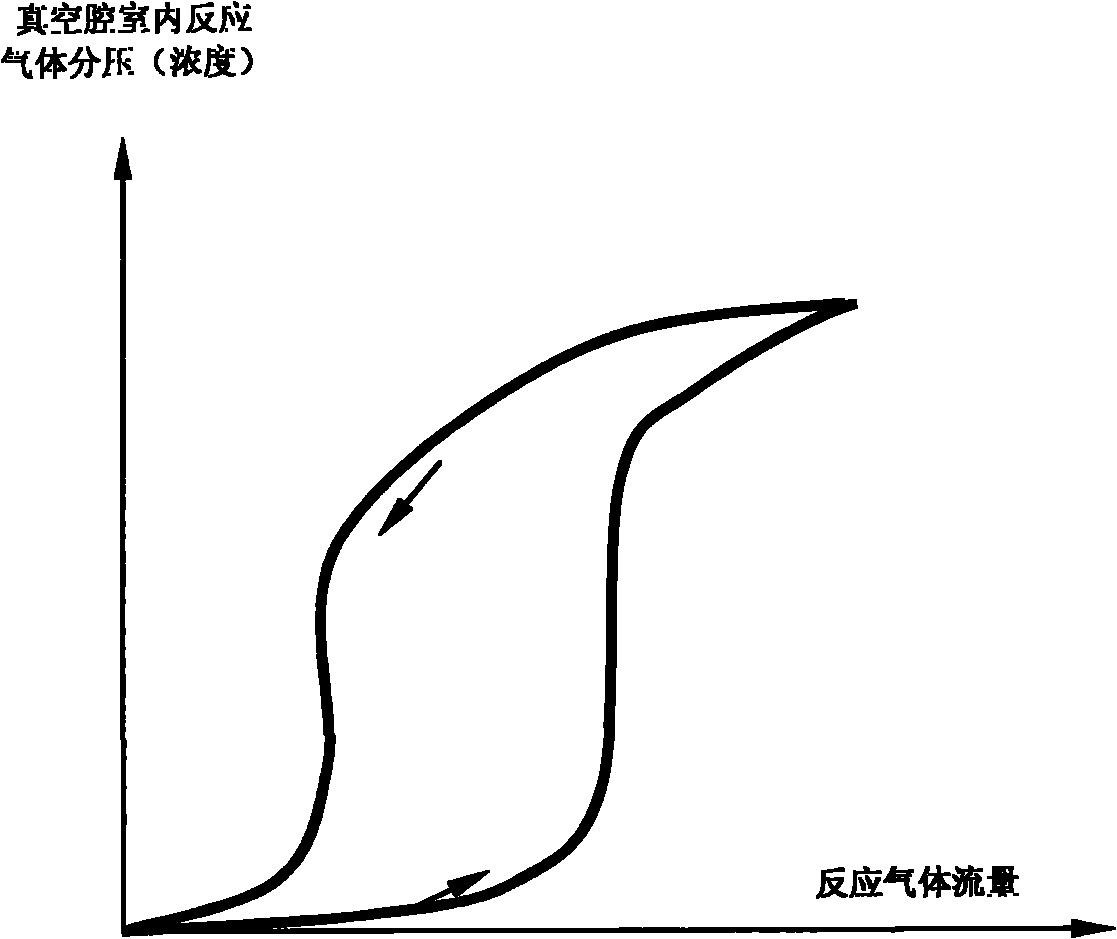

Problems solved by technology

Method used

Image

Examples

Example

[0022] Comparative test example

[0023] When sputtering thin films using Varian 2000 / 8 vacuum sputtering system, take the sputtering power of DC900W as an example. When the oxygen flow rate is lower than the critical point of 5.5SCCM, the sputtered film composition is mainly VO, and the film volume The resistivity is about 0.001Ω·cm. When the oxygen flow rate exceeds the critical point of 5.5 SCCM, the sputtering current drops sharply, and the final volume resistivity of the sputtered film is greater than 1000Ω·cm, and the main component is V 2 O 5 . It cannot sputter the +4 vanadium oxide VO 2 .

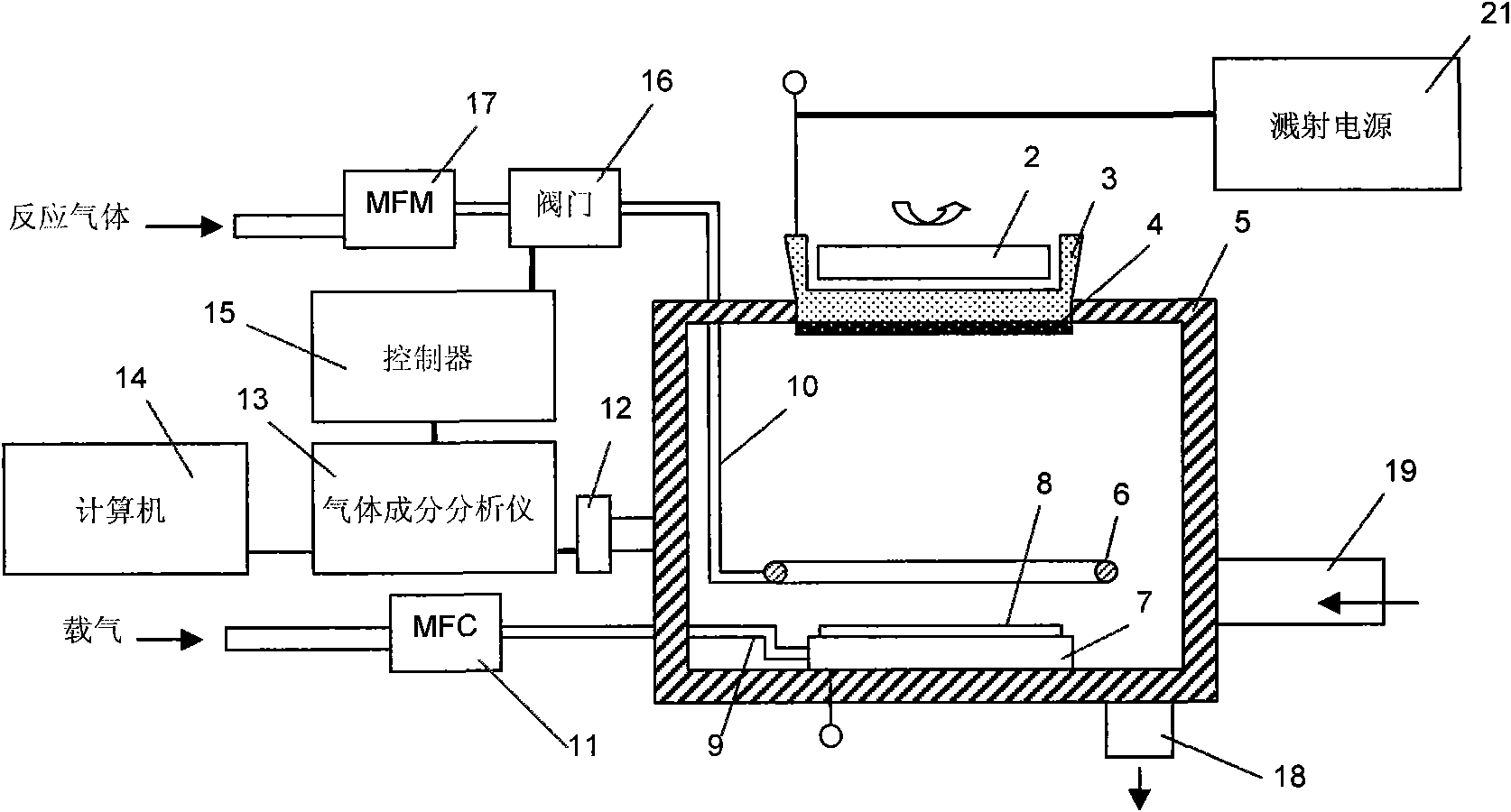

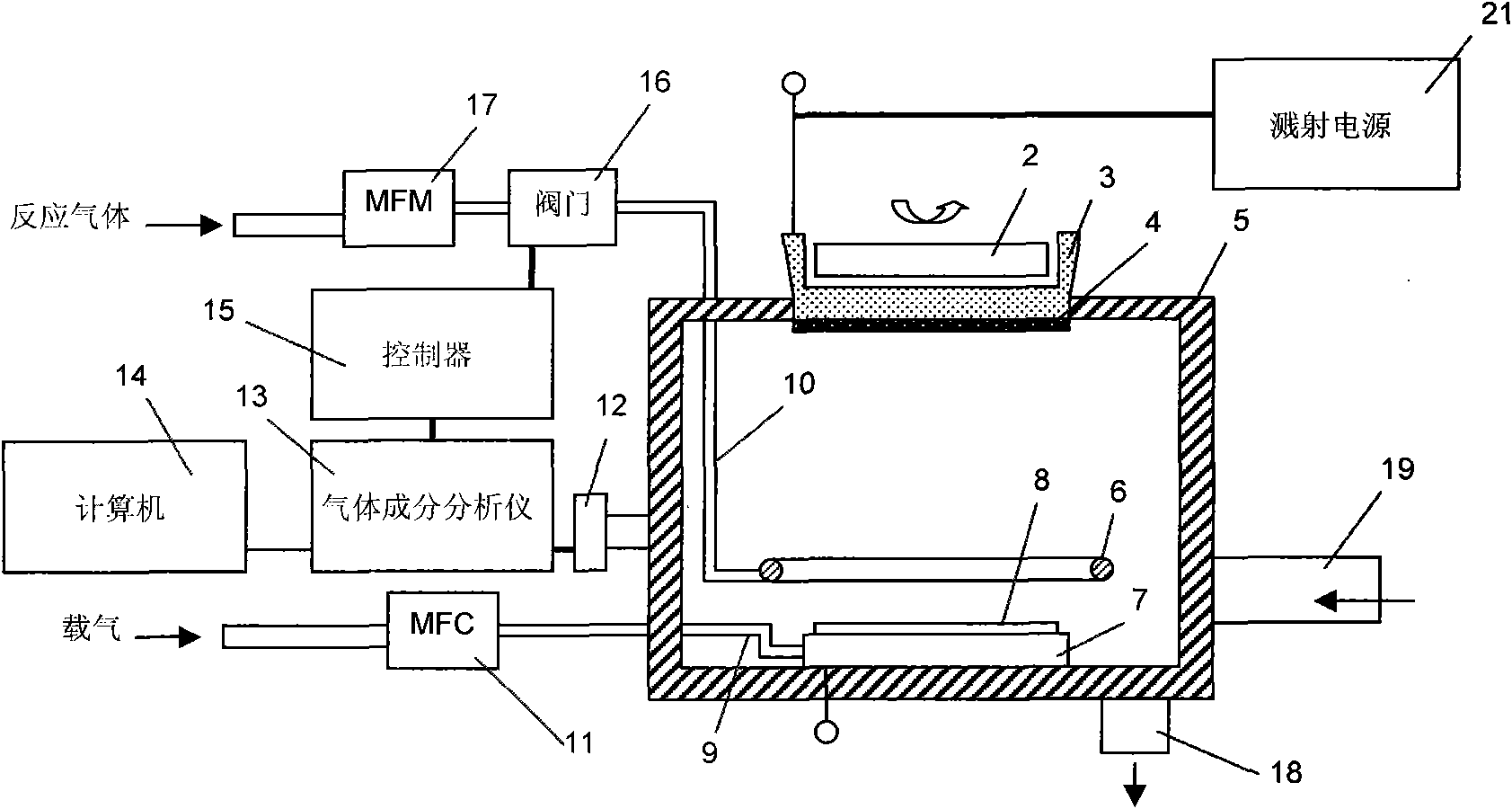

[0024] According to the present invention, the 2000 / 8 model vacuum sputtering system is modified to add the gas control system of the present invention. That is to add a ring to improve the distribution of the reaction gas on the top of the wafer stage in the vacuum chamber 5; add a residual gas detection system HPQ-2 manufactured by MKS company (its function is equivalent to the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com