High-hardness wear-resistant low light rock plate and preparation method thereof

A high-hardness, slate technology, applied in the field of architectural ceramic tiles, can solve the problems of difficult to meet the needs of consumers, poor anti-fouling, poor wear resistance, etc., to achieve enhanced mechanical strength, high strength and hardness, and wear resistance enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

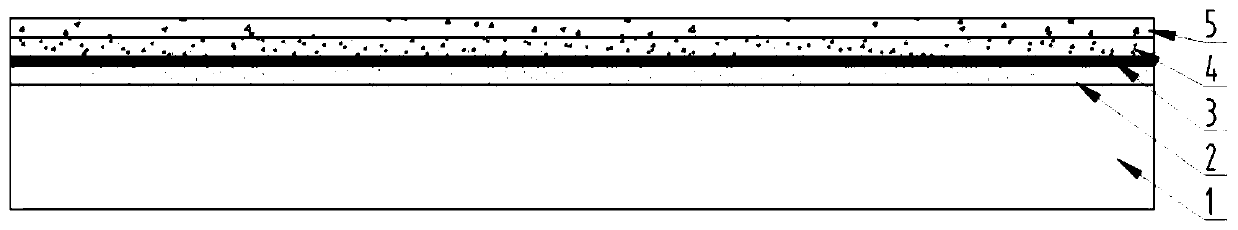

[0059] A high-hardness and wear-resistant low-gloss rock slab and its preparation method according to the present invention, its specific implementation, structure, characteristics and efficacy are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0060] 【Example】

[0061] (1) Select kaolin, feldspar, quartz and other nisha raw materials, and prepare green body porcelain powder according to conventional ceramic technology, and set it aside.

[0062] (2) Equipped with a conventional ceramic inkjet machine and equipped with blue, brown, yellow, black, orange, and packaged red inks in sequence, for standby;

[0063] Equipped with a bottom glaze, the weight percentage of the formula composition is SiO 2 :57, Al 2 o 3 : 14, CaO: 0.5, MgO: 0.25, Na 2 O: 2,K 2 O: 4.4, ZnO: 1.8, BaO: 14.7, others are ignition loss and trace impurities (preferably the weight percentage of ignition loss and trace impurities is less than 6), and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com