An induction grinding machine

A grinding machine and inductor technology, applied in cleaning methods and utensils, grain processing, pollution prevention methods, etc., can solve problems such as damage to personnel health, high labor participation, abnormal quality, etc., to improve production efficiency and high degree of automation. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

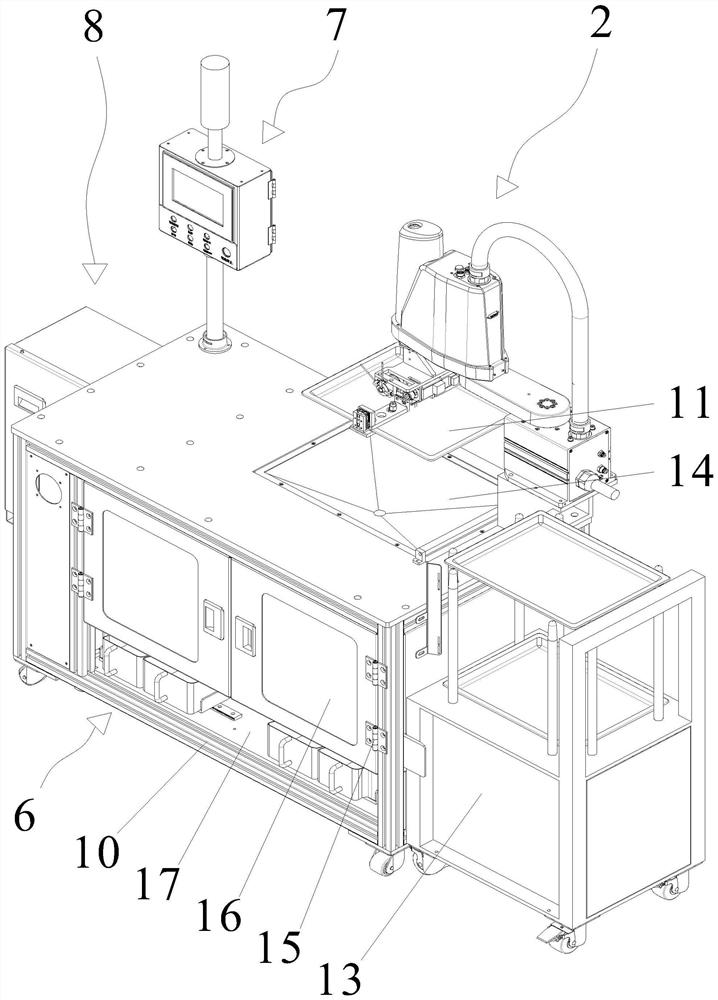

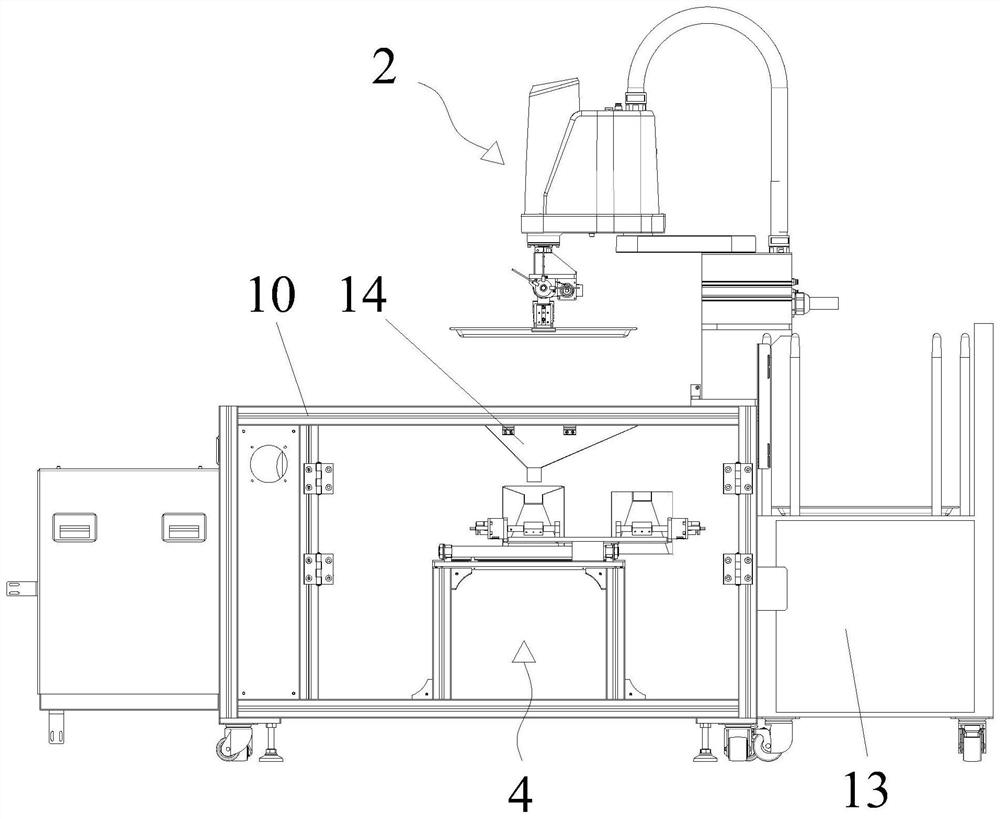

[0036] refer to Figure 1 ~ Figure 2 As shown, the present invention discloses an induction feeding and grinding machine, which includes a frame 10 , a feeding mechanism, a grinding and batching mechanism, a touch mechanism 7 and an electrical mechanism 8 .

[0037] The front of the above-mentioned frame 10 is provided with a cabinet door hinge 15 , and a cabinet door 16 is provided on the cabinet door hinge 15 . The bottom of the cabinet door 16 is provided with a pick-and-place slot. Housings 17 are provided on other sides of the frame 10 . Cabinet door 16 and housing 17 close whole frame 10 except taking and putting groove place, and its interior can effectively prevent particle from floating into the external air when grinding operation is carried out.

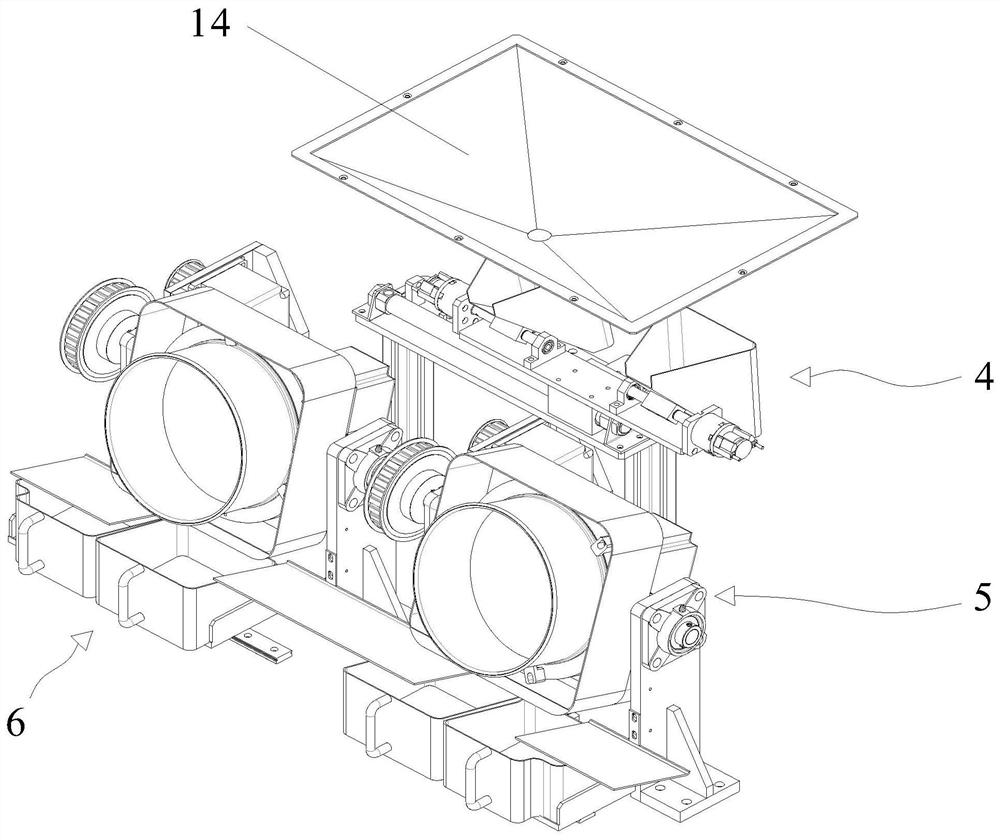

[0038] refer to Figure 3 ~ Figure 8 As shown, the above-mentioned unloading mechanism includes a manipulator 2 , a material receiving unit 4 and a delivery vehicle 13 .

[0039] The above-mentioned manipulator 2 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com