Chlorine treatment equipment of acidic etching solution recovery system, working method, control system and control method

An acid etching solution and recovery system technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of limited demand for ferric chloride liquid in waste water treatment stations and difficulties in ferric chloride treatment, etc. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

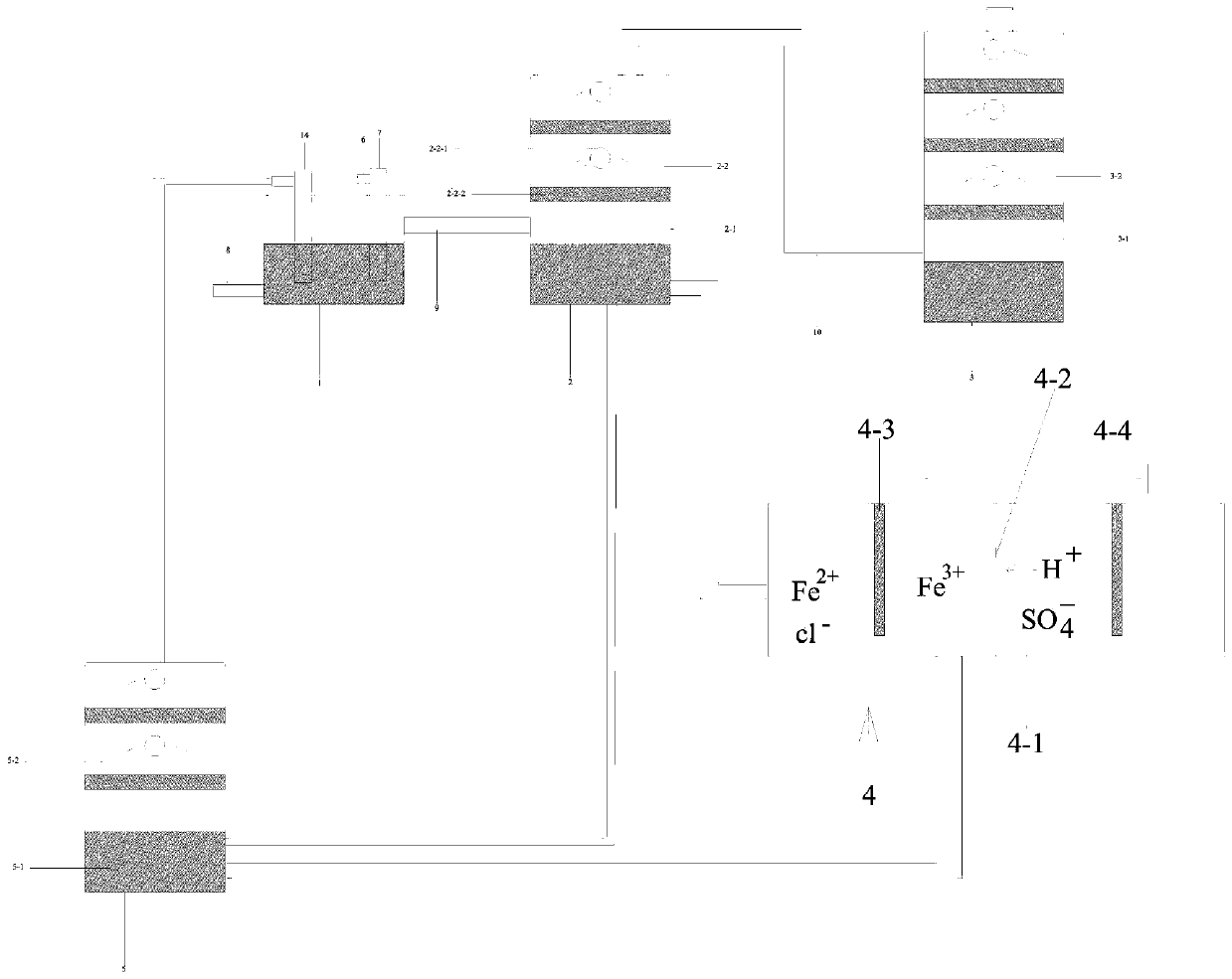

[0046] Embodiment 1, the chlorine treatment equipment of the acid etching solution recovery system, comprising: dissolving and absorbing cylinder 1, ferrous chloride absorbing device 2, liquid alkali washing tower 3, ferrous chloride regeneration device 4, vacuum volatilization device 5, chlorine gas pipeline 6. The first injector 7 and the second injector 14;

[0047]The dissolving and absorbing cylinder 1 is used to store the acid etching solution, the first injector 7 and the second injector 14 are inserted into the dissolving and absorbing cylinder 1, and the chlorine gas pipeline 6 is connected to the gas injection port of the first injector;

[0048] The liquid injection ports of the first fluidizer 7 and the second fluidizer 14 are respectively provided with a liquid pipeline, and the fluid pipeline is provided with a pump and is connected with the liquid outlet at the bottom of the dissolving and absorbing cylinder 1;

[0049] A liquid outlet and a liquid outlet pipe a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com