Grain dryer with quantitative feeding function

A grain dryer and quantitative feeding technology, applied in the direction of storing seeds, conveyors, and conveyor objects by drying, can solve the problems of insufficient drying, high labor intensity, low drying efficiency, etc., to avoid uneven drying, Improve drying efficiency and facilitate widespread use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

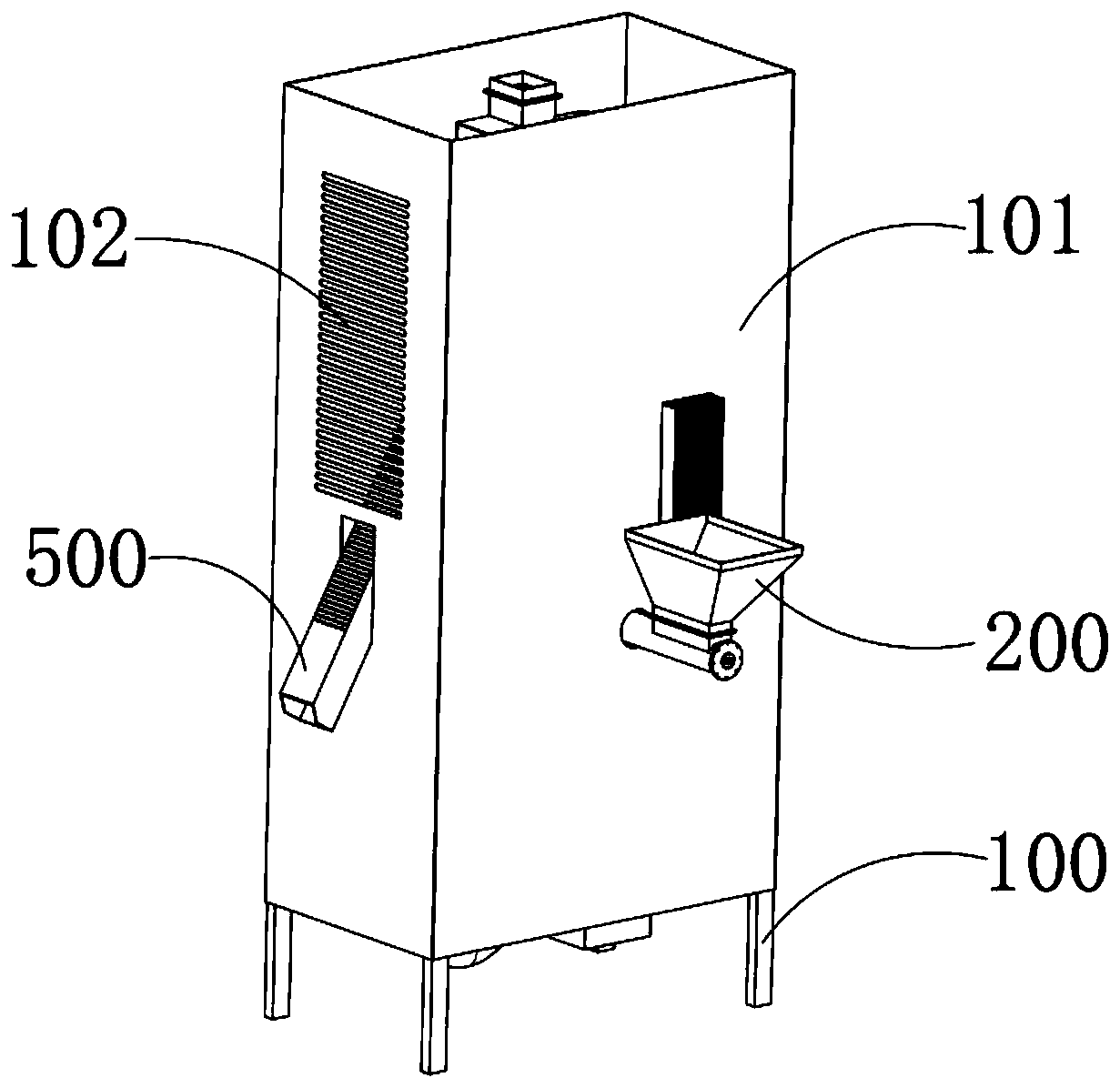

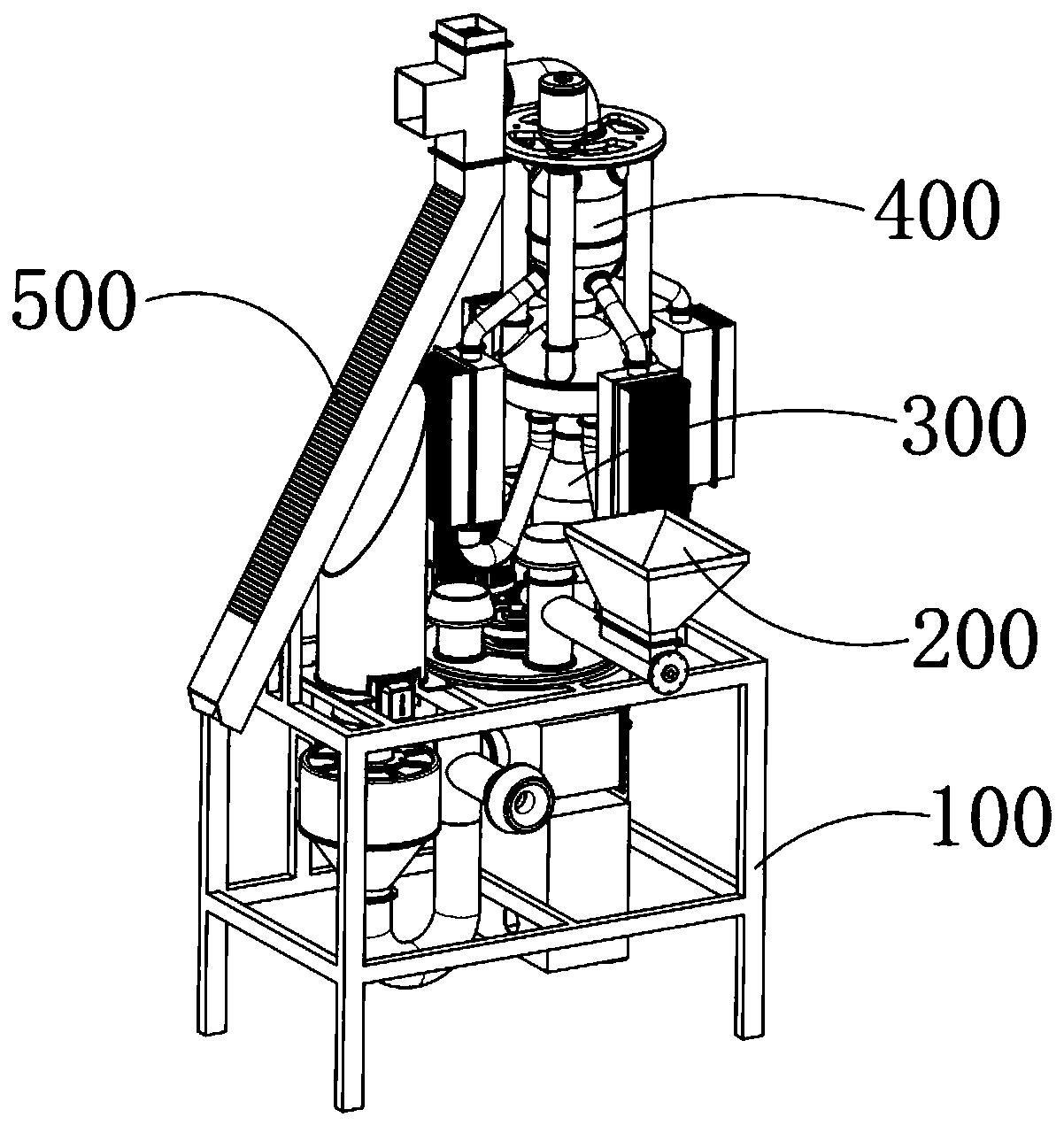

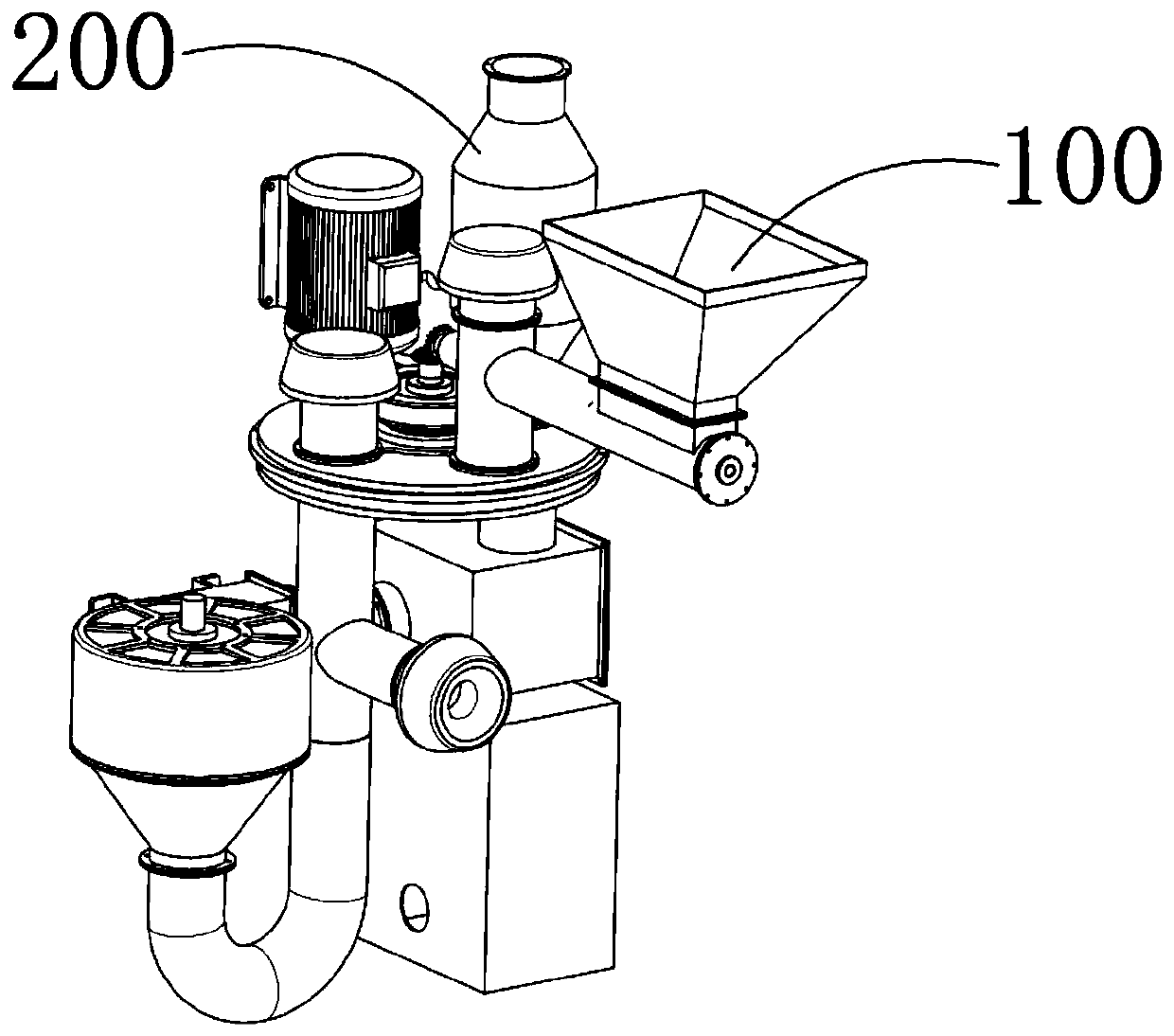

[0059] Quantitative feeding grain dryer, which includes a floor-arranged installation frame 100, on which a uniform-speed feeding mechanism 200, a drying mechanism 300, an air-drying mechanism 400, a cooling and discharging mechanism 500, and a uniform-speed feeding mechanism 200 are installed. The output end is connected to the input end of the drying mechanism 300, the output end of the drying mechanism 300 is connected to the input end of the air drying mechanism 400, and the output end of the air drying mechanism 400 is connected to the input end of the cooling discharge mechanism 500. , the output end of the cooling discharge mechanism 500 is arranged obliquely downward and points to the stacking point, the drying mechanism 300 and the air-drying mechanism 400 are arranged vertically and the air-drying mechanism 400 is located directly above the drying mechanism 300, and the uniform-speed feeding mechanism 200 is used for Accept the grain dumped by the user and transport i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com