Continuous composite molding light photovoltaic module and continuous composite molding equipment thereof

A photovoltaic module and composite molding technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as degumming, deformation, creep, and bubbling, and achieve the effect of ensuring lamination quality, high yield rate, and smooth and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

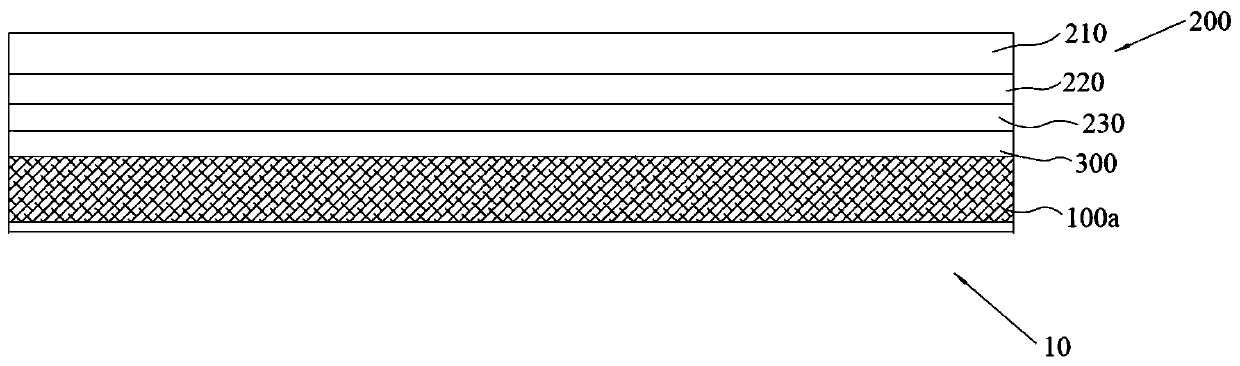

[0050] Example 1: see image 3 As shown, a continuous composite molding lightweight photovoltaic module 10 includes a photovoltaic laminate 200 and a lightweight photovoltaic backplane 100a, and a hot melt adhesive film layer is provided between the photovoltaic laminate 200 and the lightweight photovoltaic backplane 100a 300. The photovoltaic laminate 200 includes a front flexible encapsulation layer 210, a battery sheet layer 220, and a back flexible encapsulation layer 230 that are laminated and packaged as one. Specifically, preferably, in this embodiment, the front flexible encapsulation layer includes a flexible The front composite layer and the front adhesive film layer prepared from composite materials, the composite layer specifically adopts acrylic thermosetting powder coating composite fiber cloth, and its specific technical scheme can be directly referred to CN201610685536.0; the back flexible packaging layer 230 includes EVA adhesive film layer and PET , and other...

Embodiment 2

[0059]Embodiment 2: The rest of the technical solution of this embodiment 2 is the same as that of embodiment 1, the only difference is that: in this embodiment 2, the lightweight photovoltaic backplane adopts the lightweight photovoltaic backplane of Reference 2.

Embodiment 3

[0060] Embodiment 3: The rest of the technical solution of this embodiment 2 is the same as that of embodiment 1, the only difference is that: in this embodiment 3, the lightweight photovoltaic backplane adopts the lightweight photovoltaic backplane of Reference 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com