Fixing device for production and processing of liquid crystal display module

A liquid crystal display module and fixing device technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of wasted processing time, trouble, increase processing time, etc., to avoid offset shaking, simple operation steps, clamping stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

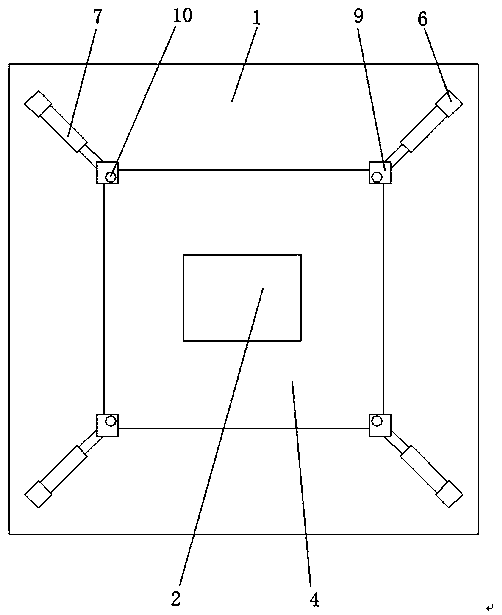

[0021] As an embodiment of the present invention, a rubber pad is fixedly connected to the lower end of the fixed rod 10 , and the rubber pad is used for buffering the mounting plate 4 and increasing friction between the mounting plate 4 and the mounting plate 4 .

[0022] As an embodiment of the present invention, the rope 12 is a nylon rope, which makes it more durable and improves the service life of the rope 12 .

[0023] As an embodiment of the present invention, the outer surface of the fixing foot 3 has a threaded structure.

[0024] As an embodiment of the present invention, the bump 5 has a hemispherical structure, and the bump 5 is made of silica gel. When placing the mounting plate 4, the bump 5 made of silica gel can be well Play the role of cushioning, reduce the vibration damage to the liquid crystal display module body 2.

[0025] As an embodiment of the present invention, the electric telescopic rod 7 is connected to the 51 single-chip microcomputer through wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com