Deep hole presplitting water coupling blasting explosive charging structure and construction method

A water-coupling and charging technology, applied in blasting and other directions, can solve the problems of difficult sealing of water-bearing formations and difficulty of sealing by charging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

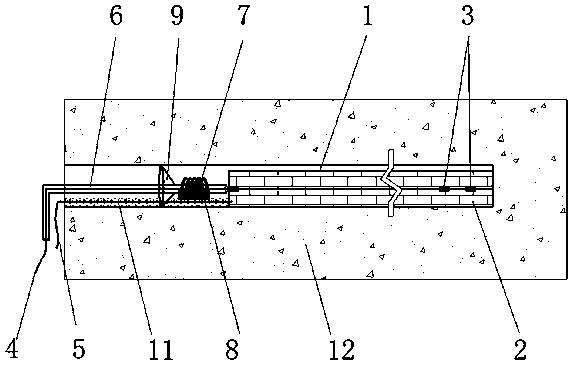

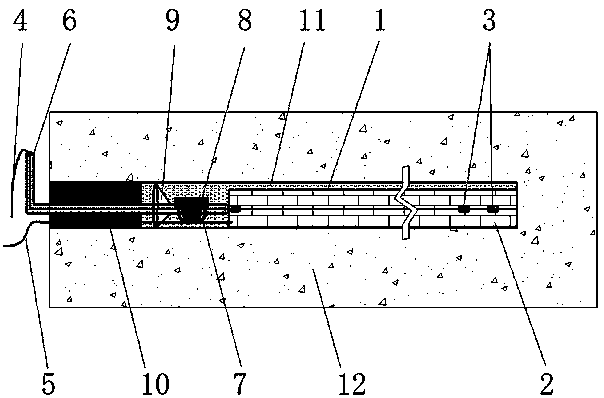

[0029] The invention relates to a charge structure for deep hole pre-split water coupled blasting, which includes a plugging section and a charge section.

[0030] The charging section is connected by a multi-section PVC charging pipe 1, the diameter of which is slightly smaller than the diameter of the blast hole, and the explosives 2 are staggered in the pipe; two rolls of explosives 2 at the bottom of the charge are respectively inserted into the electric detonator 3, and a roll of explosives 2 at the top of the charge is The electric detonator 3 is inserted, and the detonator connection wire 4 is drawn out of the hole; the three electric detonators 3 are connected in series; the PVC charging tube 1 at the end is bound with an iron wire 5, and is drawn out of the hole.

[0031] The blocking section is provided with a flow-limiting blocking device, which includes a flow-limiting water pipe 6, an expansion water stop strip 7, waterproof tinfoil 8 and a tapered sleeve 9, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com