Combined firework structure inner barrel and launching barrel without being covered with circular paper cover for sealing

A combination of fireworks and inner cylinder technology, applied in pyrotechnics, offensive equipment, weapon types, etc., can solve the problems of potential safety hazards, lower launch height of effective drugs, and incomplete sealing of paper cakes and paper cylinders, etc., to increase friction , good launch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] In order to understand the improvement of the present invention more easily, this example firstly explains the launch tube of the existing cylindrical fireworks.

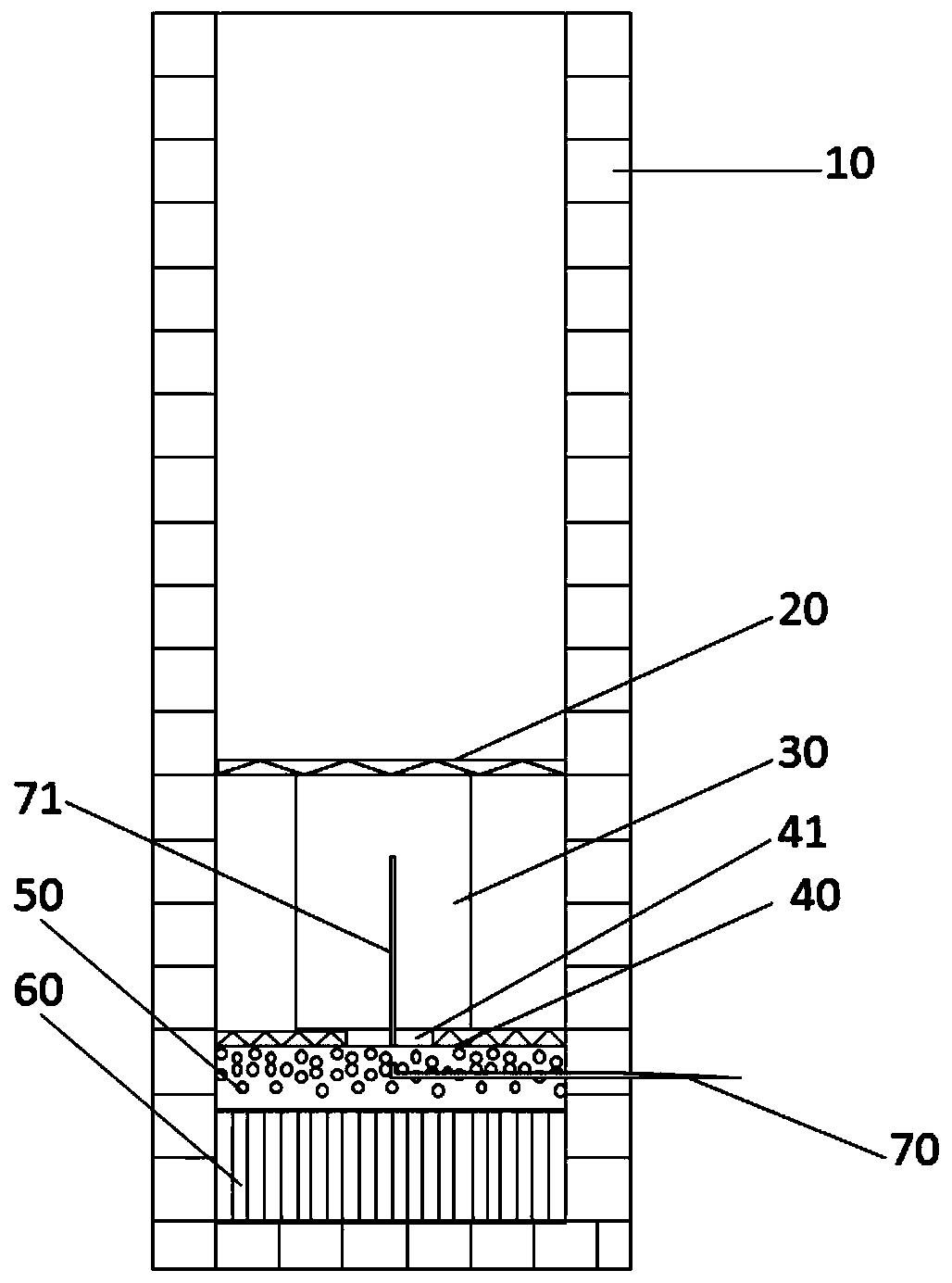

[0067] Such as figure 1 Shown is a single launching tube of the existing cylindrical fireworks, wherein the launching tube 10 is equipped with an inner cylinder body 30, the upper end of the inner cylinder body 30 is covered with a circular paper cake 20, and the lower end of the inner cylinder body 30 is cushioned with a lower cardboard 40, There is a lower cardboard ignition hole 41 in the center of the lower cardboard 40. The circular paper cake 20 forms a closed space between the inner cylinder 30 and the lower cardboard 40. The lower cardboard 40 is filled with a propellant layer 50. The medicine clay head seal layer 60, and the ignition lead wire 70 passes through the propellant powder layer 50 and is drawn out of the launch tube. After the propellant layer 50 is ignited by the ignition lead wire 70, t...

Embodiment 2

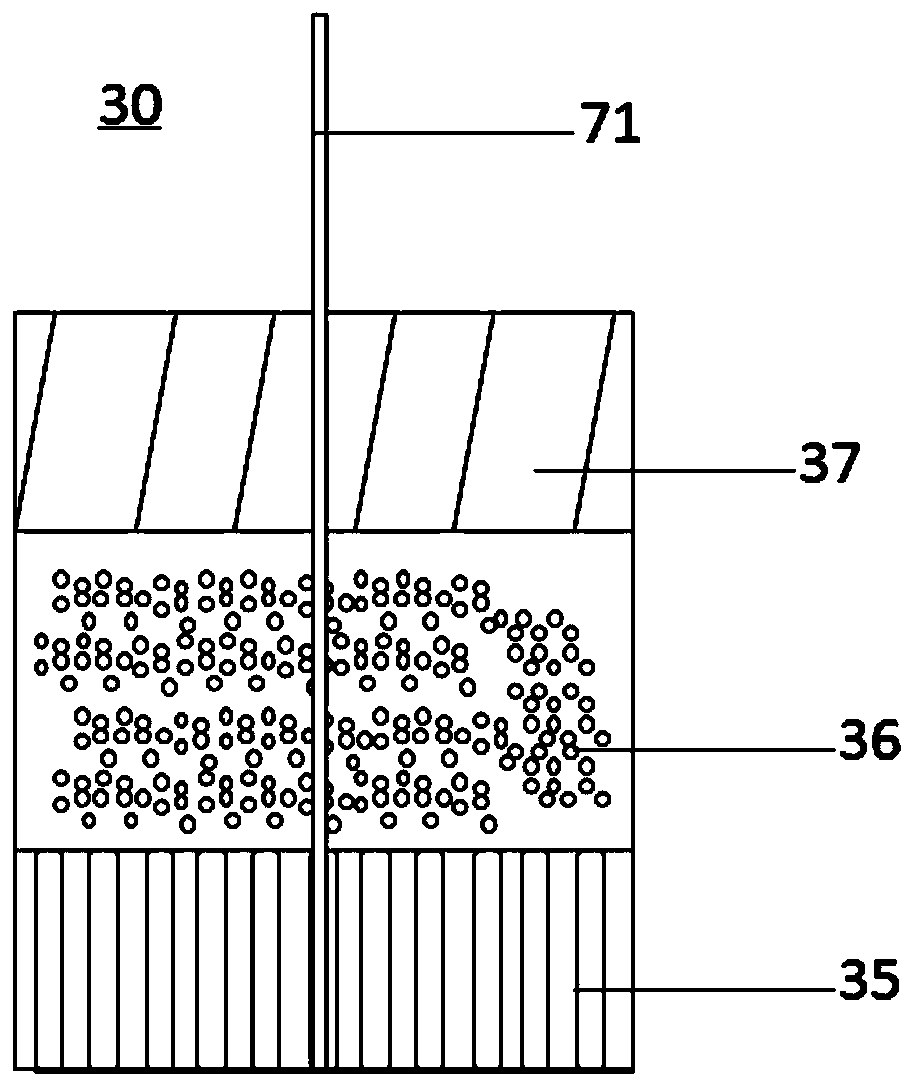

[0072] In order to solve the problems existing in the launch tube of the existing cylindrical fireworks in Example 1, the embodiment of the present invention provides a combined fireworks structure inner cylinder 30 that does not need to be covered with paper and sealed, such as Figure 4 As shown, the inner cylinder 30 has upper and lower ends, and a cylinder wall 33 connected to the upper and lower ends;

[0073] The upper end 31 of the inner cylinder is a closed structure, and the lower end 32 of the inner cylinder is an open structure;

[0074] The shape of the inner cylinder 30 is cylindrical or conical;

[0075] A supporting mechanism 34 is disposed on the cylinder wall 33 .

[0076] The material of the inner cylinder 30 is plastic material, preferably recycled plastic.

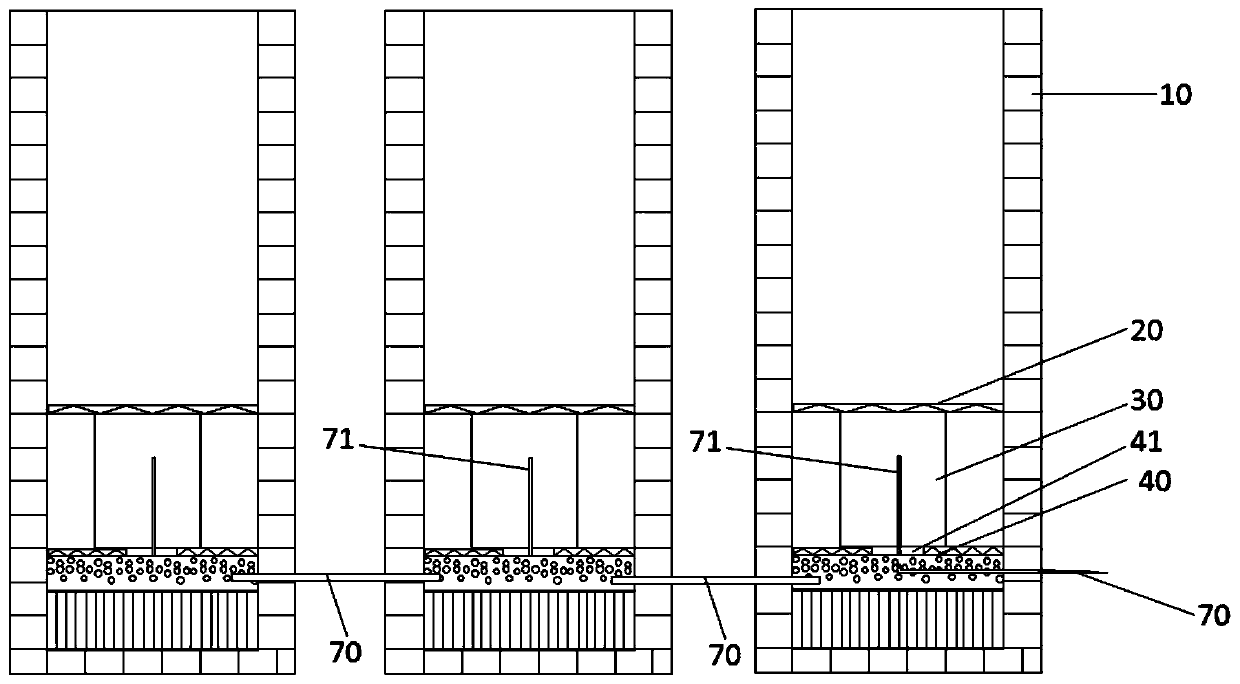

[0077] Adopt the combination firework of above-mentioned technical scheme to use inner cylinder 30, when filling, as Figure 5 As shown, the inner cylinder body 30 is first turned upside down, the in...

Embodiment 3

[0088] This example provides a kind of combined firework structure launching tube that does not need to be sealed with paper cakes, such as Figure 13 As shown, the launch tube includes

[0089] The inner cylinder 30 of Embodiment 2; and

[0090] The launch tube 10 matched with the inner cylinder 30;

[0091] The upper end of the launch tube 10 is an opening, and the bottom of the launch tube 10 is provided with an ignition hole 11 communicating with the inside and outside of the launch tube 10;

[0092] A firing chamber 80 filled with propellant is formed between the bottom of the firing cylinder 10 and the lower opening 32 of the inner cylinder;

[0093] When the inner cylinder 30 is pressed into the launch tube 10, the inner wall of the launch tube 10 is deformed under the action of the support mechanism 34, so that the inner cylinder 30 is blocked in the launch tube 10, and the outer diameter of the inner cylinder 30 0.2-3.0 mm smaller than the inner diameter of the lau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com