Novel epoxy resin bicycle lane thin-layer pavement structure

A technology of epoxy resin and bicycle lanes, which is applied in the direction of epoxy resin glue, epoxy resin paint, coating, etc., can solve the problems of poor adhesion and poor impermeability between pavement and road panels, and achieve open traffic The effect of short time, super waterproof ability and high slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

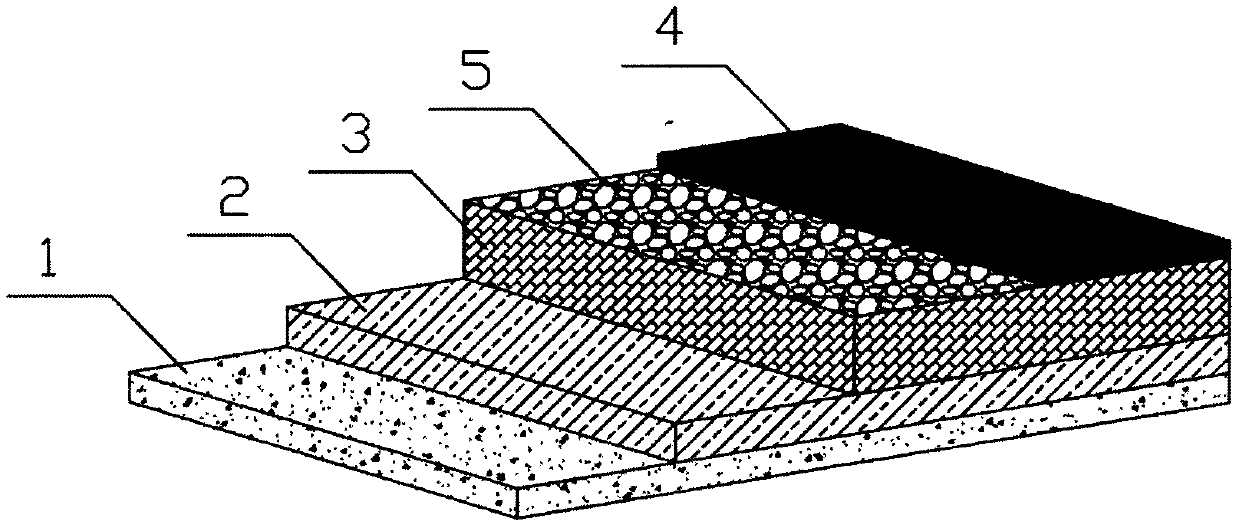

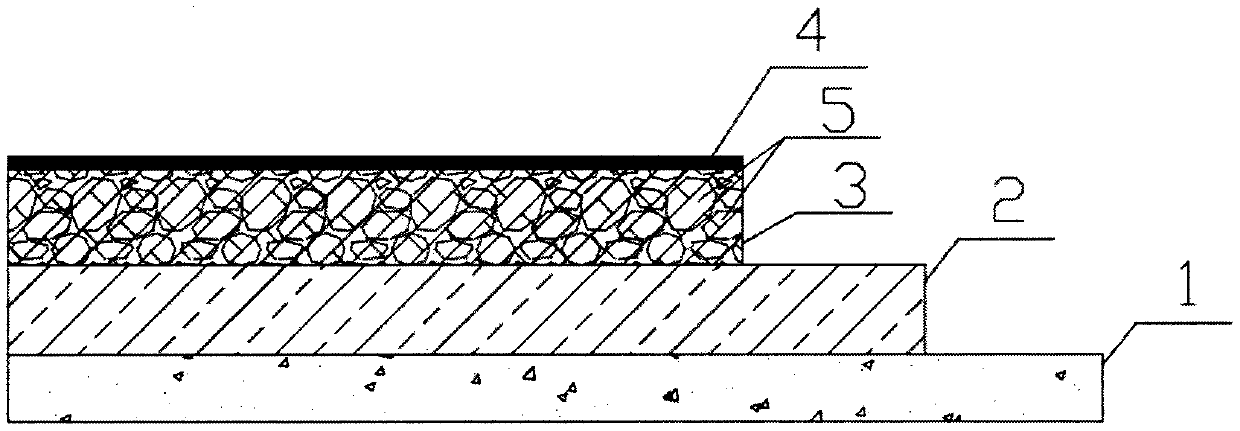

[0017] Such as figure 1 As shown, a novel epoxy resin bicycle path thin-layer pavement structure provided by the present invention is sequentially laid with a cement concrete road panel 1, an anti-seepage bonding layer 2, an anti-skid and wear-resistant layer 3, and a sealing layer 4 from bottom to top. . Such as figure 2 As shown, the anti-seepage bonding layer 2 is prepared from polyurethane modified epoxy resin, the anti-skid and wear-resistant layer 3 is prepared from polyurethane modified epoxy resin, quartz sand mixture and ceramic particles 5, and the sealing layer is made of polyurethane Prepared from modified epoxy resin. The thickness of the impervious adhesive layer 2 is 2 mm; the thickness of the anti-skid and wear-resistant layer 3 is 4 mm.

[0018] The laying steps of a novel epoxy resin bicycle path thin-layer pavement structure p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com