Nano-porous high-entropy alloy and preparation method thereof

A nanoporous, high-entropy alloy technology, applied in the field of non-precious metal nanoporous high-entropy alloys and its preparation, to achieve the effects of reducing high-precision control, simple preparation methods, and ingenious synthesis ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

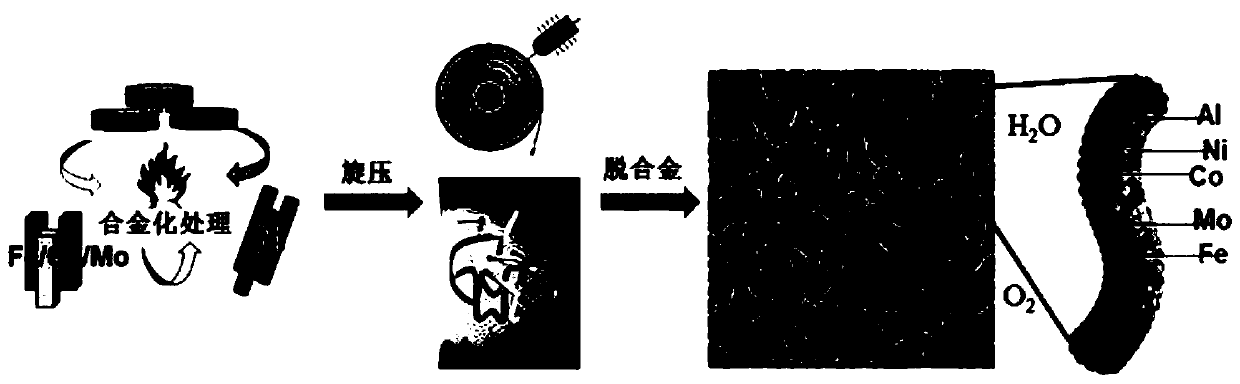

[0039] reference figure 1 The method for preparing non-precious metal nanoporous high-entropy alloys provided by the present invention is a highly controllable top-down synthesis method that combines precursor alloy design with chemical etching, combining traditional metallurgy, rapid cooling and desorption The alloy mainly includes the following steps:

[0040] Step 1. Preparation of Al-based metal block: select high-purity Al, Ni, Co, Fe and X (X: Mo, Cu, Mn, Cr, V, Zr, Nb) metals as raw materials, and the quality and purity of the five elements are all > 99.9wt.%; Then configure the five metals required according to the target composition, for example: Al 97 Ni 1.5 Co 0.5 Fe 0.5 X 0.5 , Or configure the six metals required according to the target composition, for example: Al 96.5 Ni 1.5 Co 0.5 Fe 0.5 Cu 0.5 Mo 0.5 The marked composition is in atomic percentage; the mixed metal raw materials are placed in a vacuum melting furnace and fully smelted under the protection of argon (...

Embodiment 1

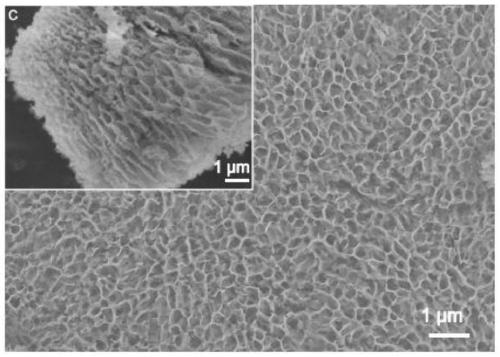

[0046] figure 2 It is a scanning electron microscope (SEM) image of the nanoporous high-entropy alloy AlNiCoFeMo prepared in Example 1 of the present invention. In the preparation process, after selective etching of Al, the pure Al phase is removed and Al is selectively etched 3 Ni-phase (e.g. Al 3 NiCoFeMo) to form nanoporous structured Al-Ni-Co-Fe-Mo. It can be seen from the figure that the dealloyed five-element Al 97 Ni 1.5 Co 0.5 Fe 0.5 Mo 0.5 The SEM image of the alloy shows a macroporous channel layer with a size range of 200-300nm and a thin solid wall layer. Among them, such as figure 2 As shown, the nanopore channel passes through the entire sample, and some smaller nanopores are distributed on the thin wall.

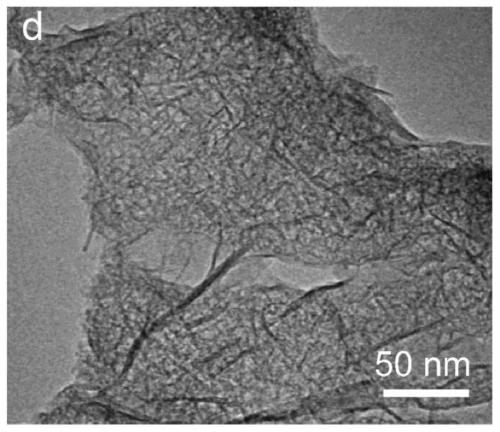

[0047] image 3 It is a low-power transmission electron microscope (TEM) image of the AlNiCoFeMo nanoporous high-entropy alloy AlNiCoFeMo prepared in this embodiment. It further confirmed the existence of smaller nanopores in the thin wall, the size of which w...

Embodiment 2

[0053] The difference from Example 1 is that the nanoporous high-entropy alloy is a six-element nanoporous high-entropy alloy AlNiCoFeCuMo, and according to the target composition Al 96.5 Ni 1.5 Co 0.5 Fe 0.5 Cu 0.5 Mo 0.5 The six metals required for the configuration are indicated in atomic percentages.

[0054] Picture 9 It is a scanning electron microscope (SEM) image of the nanoporous high-entropy alloy AlNiCoFeCuMo prepared in this example. Picture 10 It is a low-power transmission electron microscope (TEM) image of the nanoporous high-entropy alloy AlNiCoFeCuMo prepared in this example. Picture 11 It is a high-resolution transmission electron microscope (HRTEM) image of the nanoporous high-entropy alloy AlNiCoFeCuMo prepared in this example. Picture 12 It is a scanning transmission electron microscope-energy spectrometer (STEM-EDS) map of the AlNiCoFeCuMo nanoporous high-entropy alloy AlNiCoFeCuMo prepared in this embodiment. For the six-element nanoporous high-entropy al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com