Ende staged gasification system for dry cleaning treatment of fly ash

A gasification system, Ender's technology, applied in the field of Ender graded gasification system, can solve the problems of large water consumption, difficult black water treatment, increased cost, etc., and achieve the effect of less ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

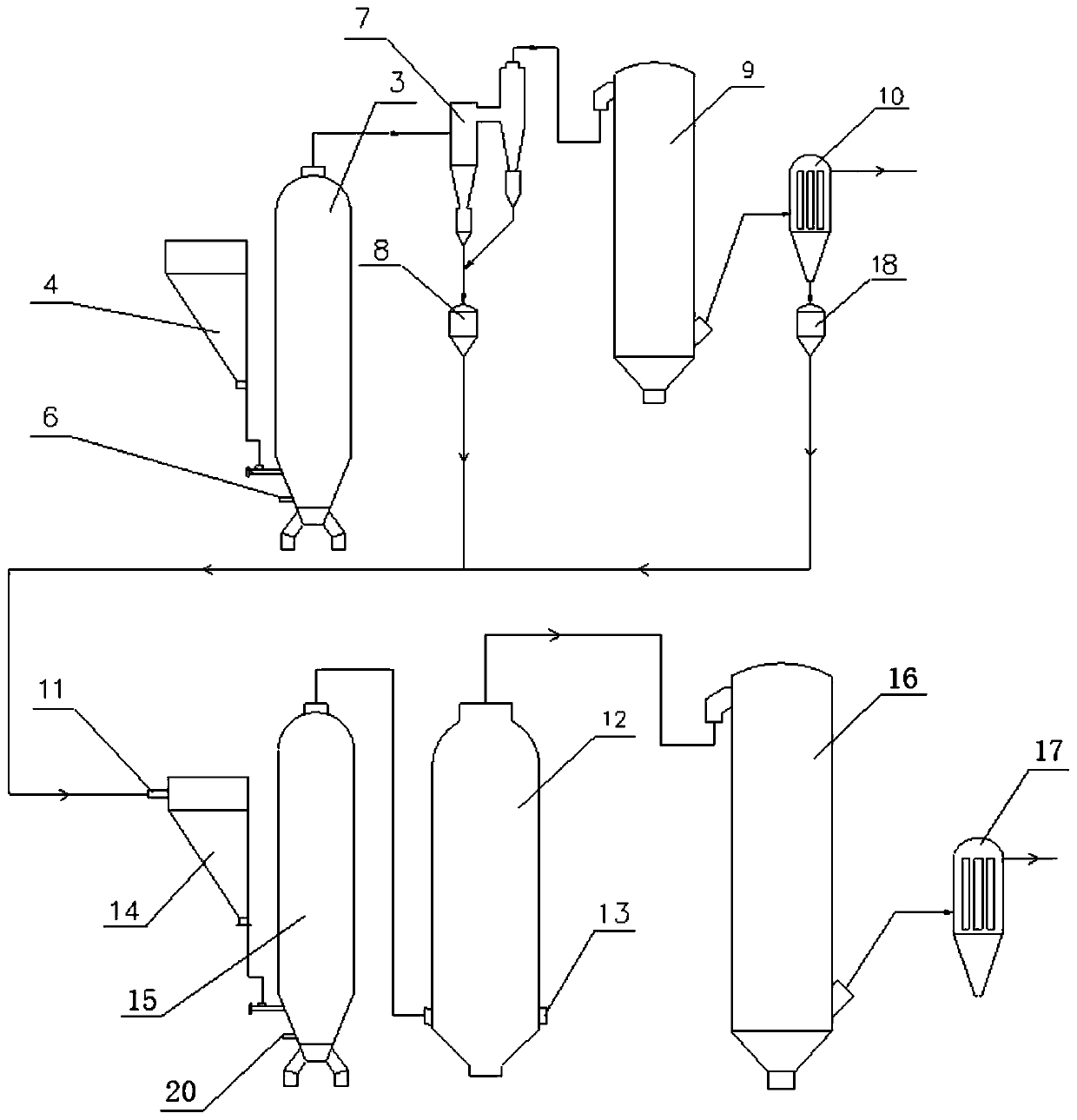

[0027] Specific implementation mode one: combine figure 1 To illustrate this embodiment, the Ender classified gasification system for fly ash dry cleaning treatment in this embodiment includes a first coal storage bin 4, a first Ender gasifier 3, a cyclone dust collector 7, a first ash hopper 8, a first waste Heat boiler 9, first multi-stage bag filter 10, second ash hopper 18, second coal storage bunker 14, second Ender gasifier 15, entrained flow gasifier 12, second waste heat boiler 16 and second Multi-stage bag filter 17,

[0028] The outlet of the first coal storage bunker 4 communicates with the entrance of the first Ende gasifier 3, and the top of the first Ende gasifier 3 communicates with the cyclone dust collector 7. The top of the dust collector 7 communicates with the first waste heat boiler 9, the outlet of the first waste heat boiler 9 is connected with the first multi-stage bag filter 10, and the lower part of the first multi-stage bag filter 10 is provided wit...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the first coal storage bunker 4 is also provided with a first coal feeder 1 and a first spiral coal feeder 2, and the first coal feeder 1 passes through the first coal feeder. A coal screw conveyor 2 is connected with the first coal storage bunker 4 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the second coal storage bunker 14 is also provided with a second coal feeding hopper 21 and a second screw coal feeder 22, and the second coal feeding hopper 21 passes through the second coal feeding hopper. Two spiral coal feeders 22 are connected with the second coal storage bunker 14 . Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com