Liquid cooling shell vacuum brazing method

A brazing method and vacuum technology, applied in the field of metal welding, can solve problems such as clogging of water channels, reduce overflow, ensure welding tightness, and increase set temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

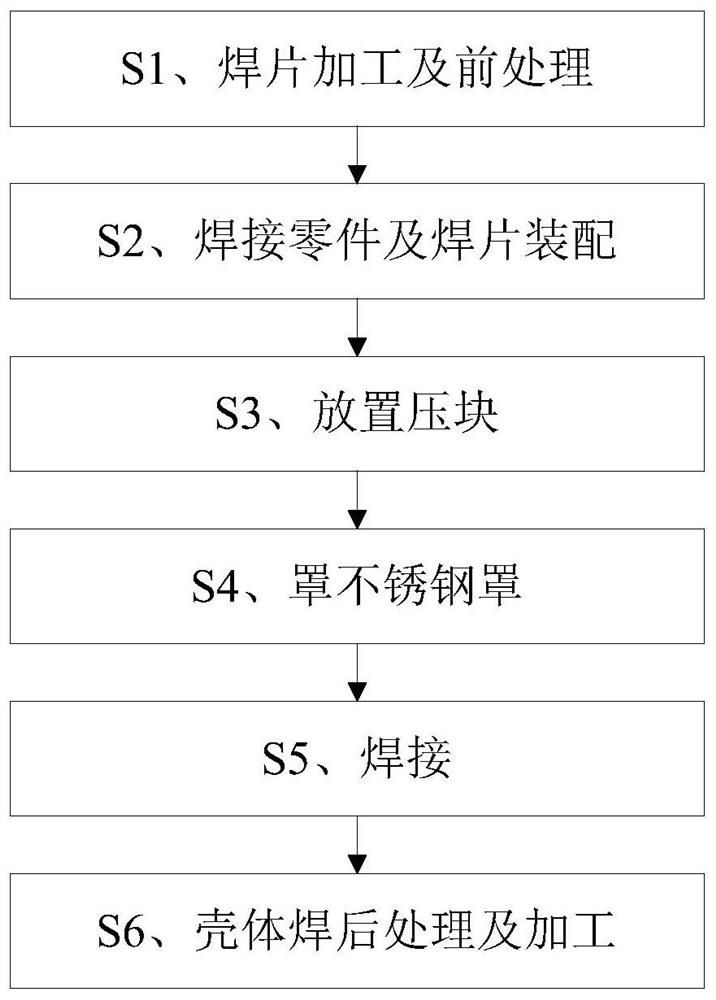

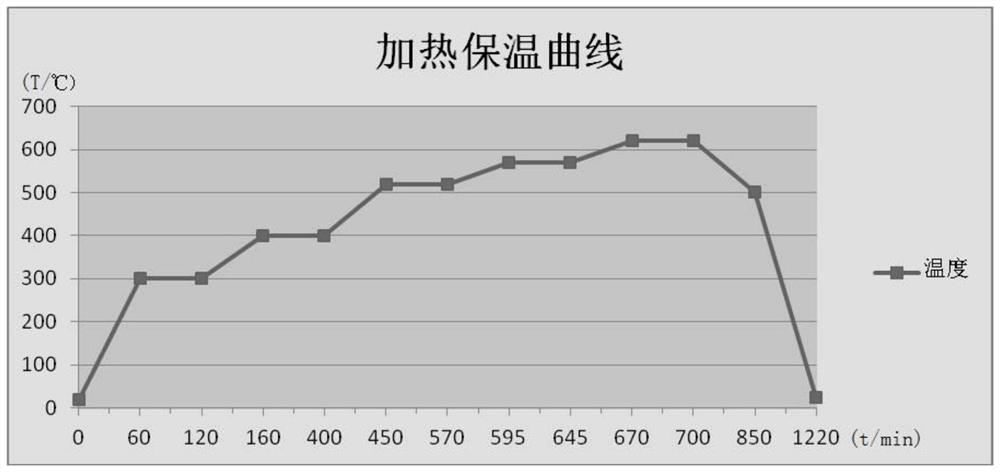

[0025] A vacuum brazing method for a liquid-cooled shell, comprising the following steps:

[0026] S1. Solder tab processing and pretreatment: Cut the solder tab according to the cross-sectional shape of the welded part, and polish the cut solder tab, and then use acetone to wipe and dry it;

[0027] The solder sheet is made of AlSiMg10-1.5 with a thickness of 0.05mm and a melting point of 559°C-591°C.

[0028] S2. Assembly of welded parts and solder tabs: evenly place a number of solder tabs between two welded parts, and place them on a cleaned welding plate after assembly; the welded plate is also cleaned with acetone;

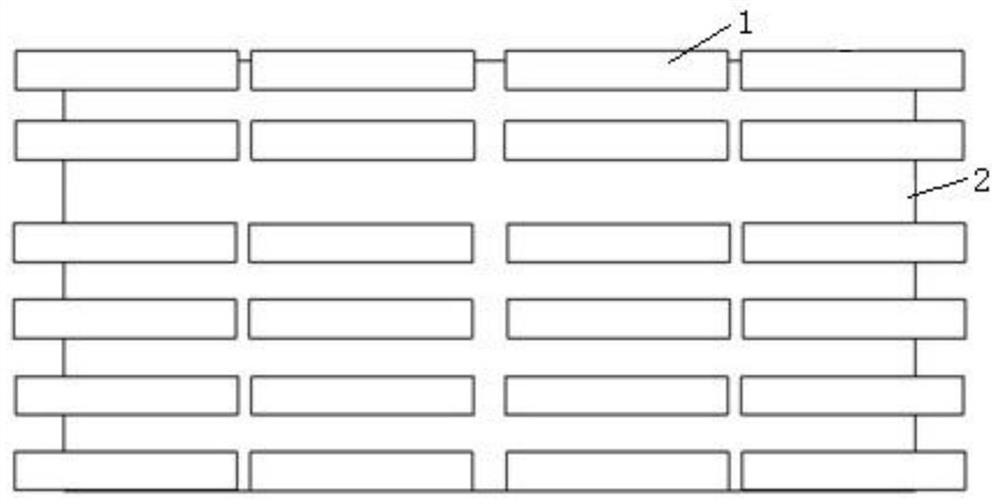

[0029] S3. Placing the briquetting block: adopt the single-piece briquetting block 1, and compact it on the surface of the workpiece 2 according to the placement position of the welding piece;

[0030] combine figure 2 , the quantity of the briquettes 1 is 24, and the weight of a single briquette 1 is 1.37kg. The placement positions of the pressing block...

Embodiment 2

[0037] A vacuum brazing method for a liquid-cooled shell, comprising the following steps:

[0038] S1. Solder tab processing and pretreatment: Cut the solder tab according to the cross-sectional shape of the welded part, and polish the cut solder tab, and then use acetone to wipe and dry it;

[0039] The solder sheet is made of AlSiMg10-1.5 with a thickness of 0.07mm and a melting point of 559°C-591°C.

[0040] S2. Assembly of welded parts and solder tabs: evenly place a number of solder tabs between two welded parts, and place them on a cleaned welding plate after assembly; the welded plate is also cleaned with acetone;

[0041] S3. Placing the briquetting block: adopt the single-piece briquetting block 1, and compact it on the surface of the workpiece 2 according to the placement position of the welding piece;

[0042] The quantity of the briquettes 1 is 28, and the weight of a single briquette 1 is 1.23kg. The placement position of the pressing block 1 corresponds to the ...

Embodiment 3

[0049] A vacuum brazing method for a liquid-cooled shell, comprising the following steps:

[0050] S1. Solder tab processing and pretreatment: Cut the solder tab according to the cross-sectional shape of the welded part, and polish the cut solder tab, and then use acetone to wipe and dry it;

[0051] The solder sheet is made of AlSiMg10-1.5 with a thickness of 0.1mm and a melting point of 559°C-591°C.

[0052] S2. Assembly of welded parts and solder tabs: evenly place a number of solder tabs between two welded parts, and place them on a cleaned welding plate after assembly; the welded plate is also cleaned with acetone;

[0053] S3. Placing the briquetting block: adopt the single-piece briquetting block 1, and compact it on the surface of the workpiece 2 according to the placement position of the welding piece;

[0054] The quantity of the briquette 1 is 32 pieces, and the weight of a single briquette 1 is 1.08kg. The placement position of the pressing block 1 corresponds to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com