Polyaniline/graphene capsule three-dimensional hollow hybrid structure as well as preparation method and application thereof

A graphene and polyaniline technology, applied in the field of gas sensors, can solve problems such as high working temperature, hindering commercial application, unstable chemical properties of metal oxides, etc., to achieve rapid response improvement, which is conducive to rapid response and recovery, Effect of Excellent Response Characteristics and Sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

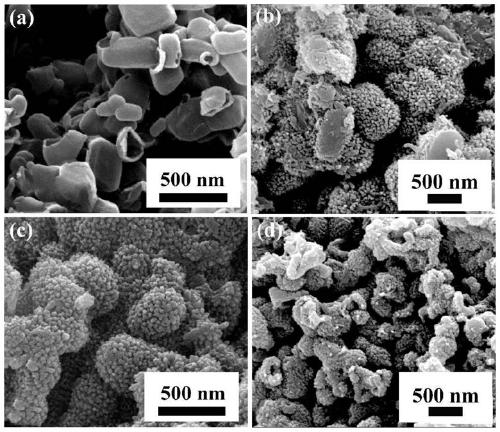

[0036] A kind of preparation method of polyaniline / graphene capsule (PANI / GCs) three-dimensional hollow hybrid structure, comprises the following steps:

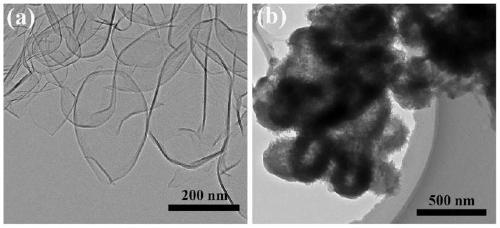

[0037]Step 1, using chemical vapor deposition (CVD), using nano-zinc oxide particles as a template, and acetylene as a carbon source to prepare graphene capsules;

[0038] 1.1. Put 20g of nano-ZnO particles into a quartz tube, place the quartz tube in a rotary CVD furnace with a rotation speed of 5 rpm, and heat it to 650 °C at a rate of 10 °C / min in an argon atmosphere. , with the gas flow rate of 30mL / min, acetylene gas was introduced as the reaction gas, and the reaction time was 30min. After the reaction was completed, it was naturally cooled to room temperature under an argon atmosphere, and the product was taken out to grow coated graphene on the surface of nano-ZnO particles. Nanolayers, resulting in graphene / zinc oxide composites;

[0039] 1.2. Soak the product obtained in step 1 in nitric acid (in nitric acid solut...

Embodiment 2

[0045] Compared with embodiment 1, this embodiment differs in that:

[0046] The specific process of step 2 is: take 3 mg of the graphene capsule GCs prepared in step 1 and disperse them in 100 mL of deionized water, and ultrasonically disperse them evenly, and place the obtained dispersion in an ice bath at 0°C.

Embodiment 3

[0048] Compared with embodiment 1, this embodiment differs in that:

[0049] The specific process of step 2 is: take 9 mg of the graphene capsule GCs prepared in step 1 and disperse them in 100 mL of deionized water, and ultrasonically disperse them evenly, and place the obtained dispersion in an ice bath at 0°C.

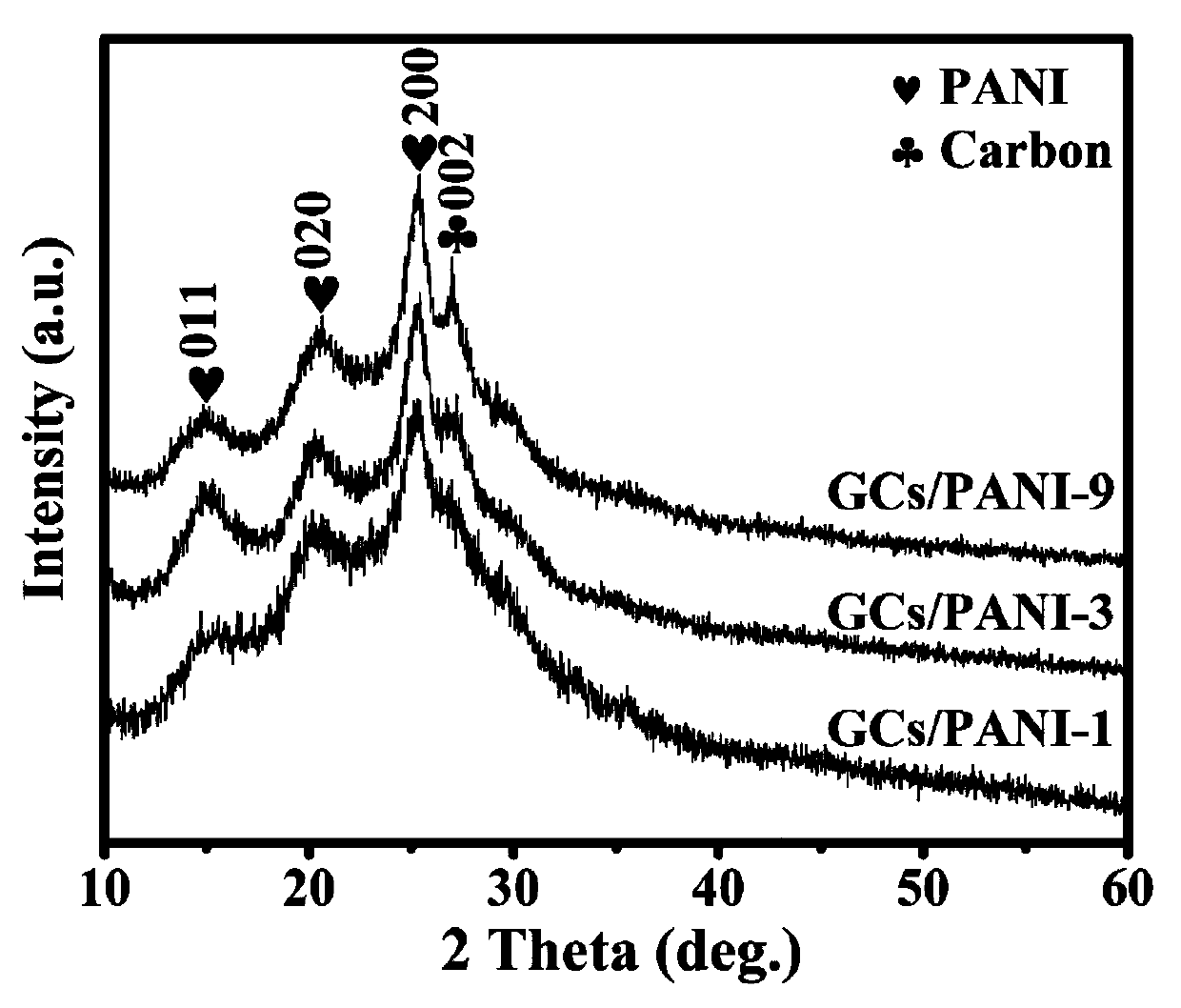

[0050] The mixed solution after the complete reaction of Example 1, Example 2 and Example 3 was washed alternately with deionized water and ethanol six times respectively. During the washing process, the centrifugal speed of the centrifuge was set to 3800r / min, so that the suspension After centrifugal separation, the obtained samples were dried at 80° C., and were respectively recorded as PANI / GCs-1 (Example 1), PANI / GCs-3 (Example 2) and PANI / GCs-9 (Example 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com