Combined potato digging shovel

A potato and excavating shovel technology, which is applied to excavators, excavating harvesters, agricultural machinery and implements, etc., can solve the problems of increased workload, large impact of potato excavation, and missed potato collection, etc., to prevent damage and facilitate long-term use. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

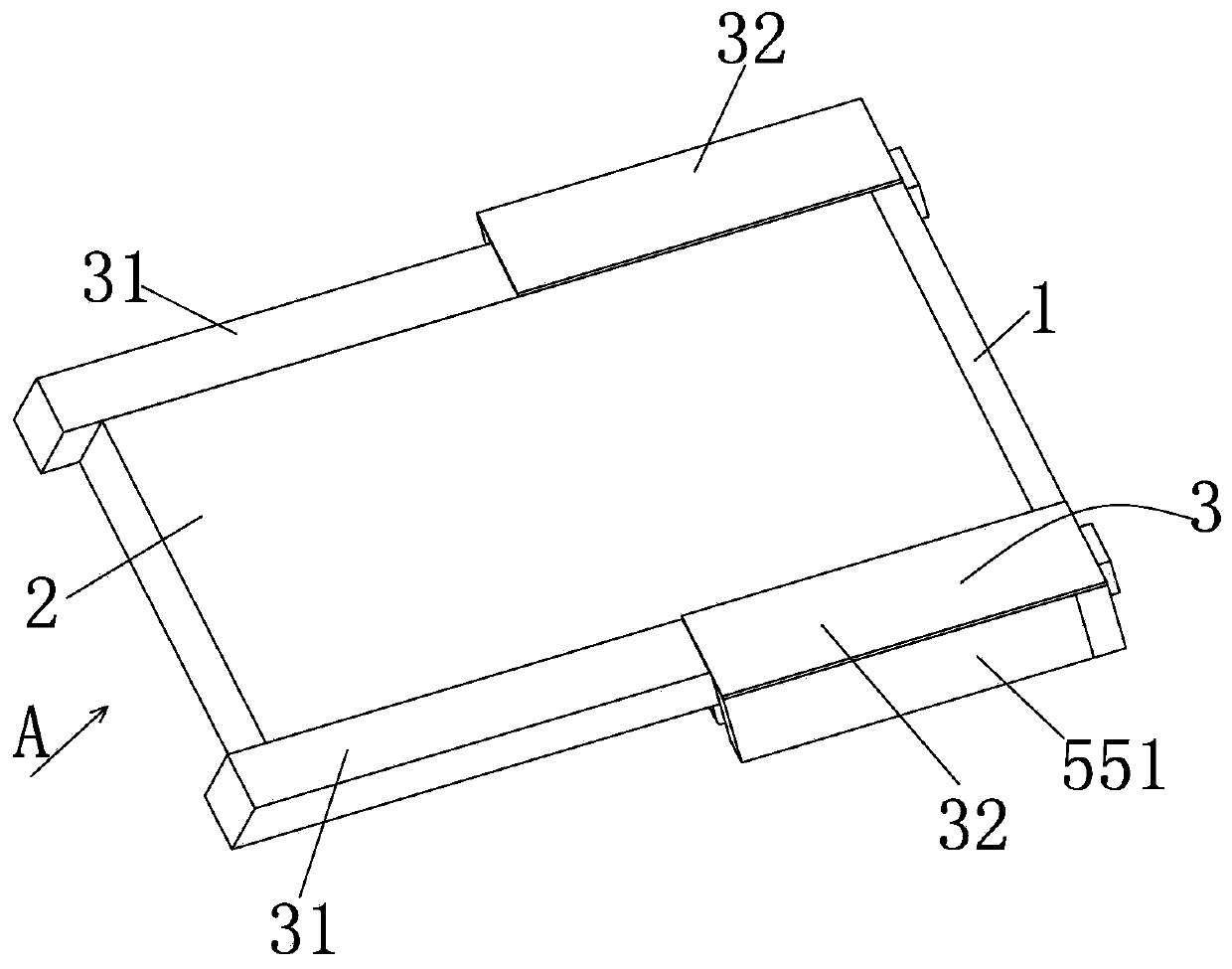

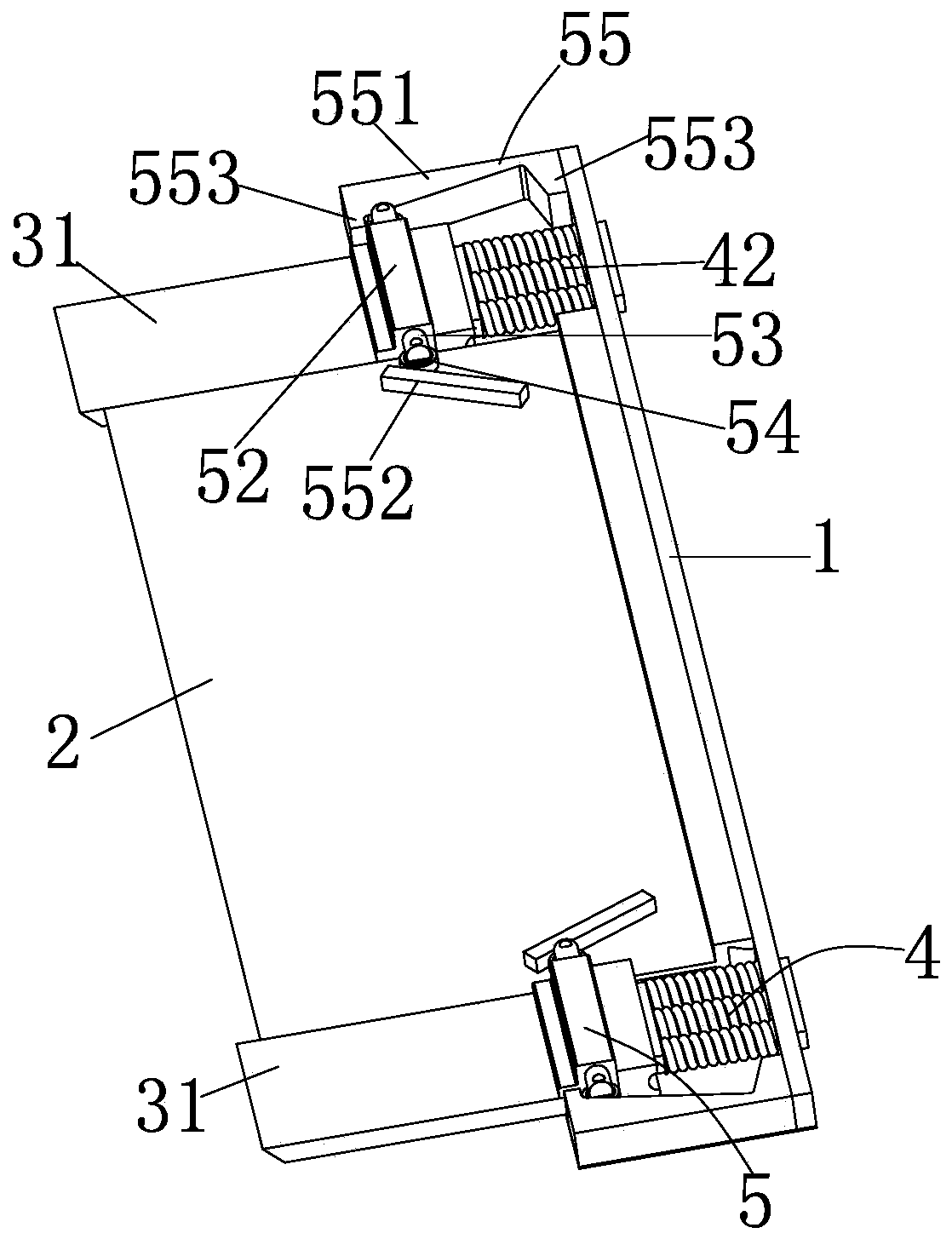

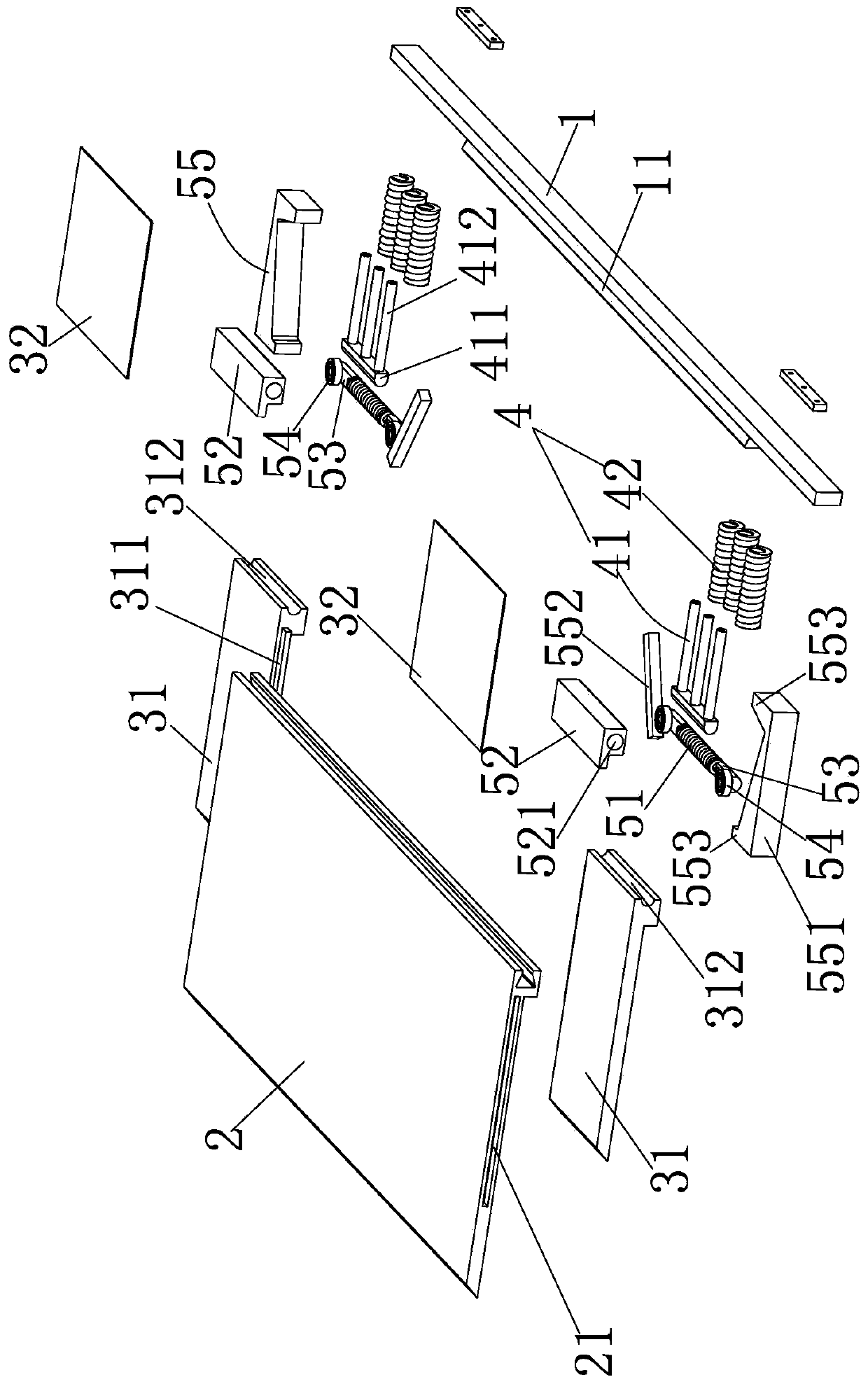

[0036] This embodiment discloses a combined potato digging shovel, such as Figure 1 to Figure 3As shown, the mounting part 1 and the middle shovel 2 installed on the shovel frame; the mounting part 1 is provided with a first transverse rail 11; the middle shovel 2 is installed on the first transverse rail 11; both sides of the middle shovel 2 are equipped with automatic adjustment Assembly 3, the automatic adjustment assembly 3 includes two balance shovels 31, the balance shovels 31 are respectively located on both sides of the middle shovel 2; when the two balance shovels 31 receive different resistances, push the middle shovel 2 along the first transverse track 11 Move left and right to two balance shovels 31 stressed balances. The automatic adjustment assembly 3 includes a longitudinal adjustment mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com