A Multifunctional Electret Generator Based on Permanent Magnetic Levitation Gyro

A magnetic levitation gyroscope and electret technology, applied in induction generators, triboelectric generators and other directions, can solve the problems of low vibration wind speed, small contact area, easy damage of surface nanostructures, etc., to overcome stress concentration, increase Vibration frequency bandwidth, effect of increasing the rate of change of intrinsic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

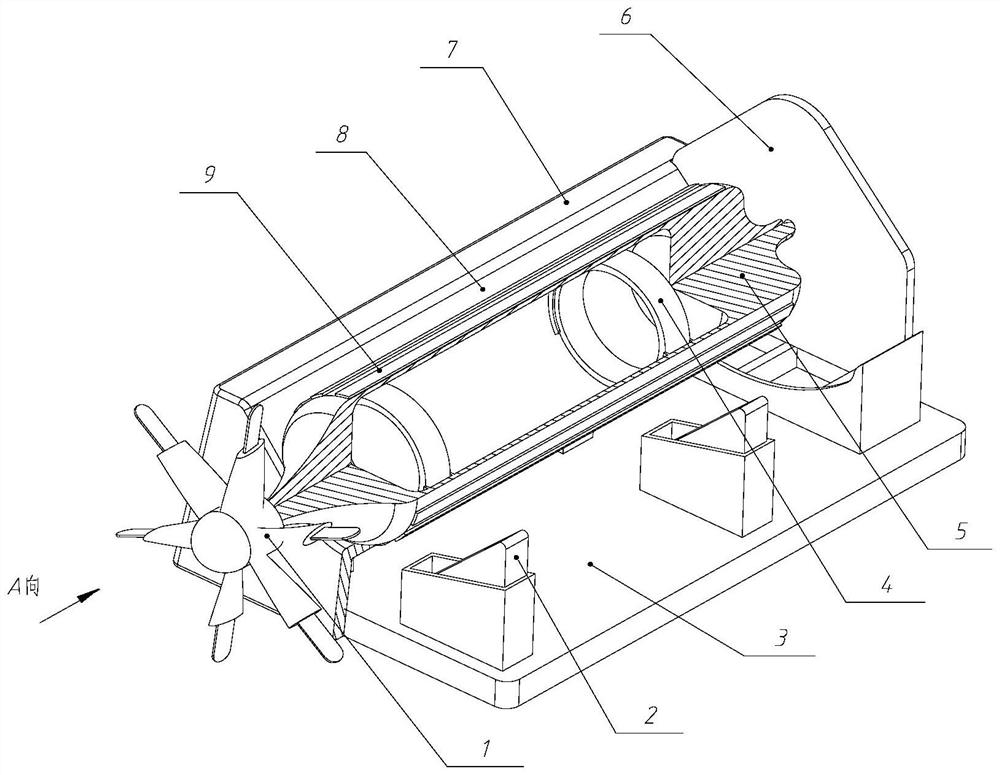

Embodiment 1

[0035] Such as Picture 1-1 As shown, the essence of this embodiment is a variable capacitor that utilizes an electret to provide a bias voltage. The multifunctional electret generator of the permanent magnetic levitation gyroscope mainly includes a blade rotor 1, a triangular permanent magnet 2, an insulating substrate 3, a ring Permanent magnet 4, vibration pickup rotor 5, positioning block 6, fixed magnet cover 7, substrate electrode 8 and electret polymer film 9, wherein: insulating substrate 3, fixed magnet cover 7, vibration pickup rotor 5 from bottom to bottom Arranged in sequence on the top, the positioning block 6 is inserted into the groove at the corresponding position of the insulating substrate. The structure composed of the triangular permanent magnet 2, the insulating substrate 3, the positioning block 6 and the fixed magnet cover 7 according to the assembly sequence is called an external fixed component. The structure composed of the blade rotor 1, the vibratio...

Embodiment 2

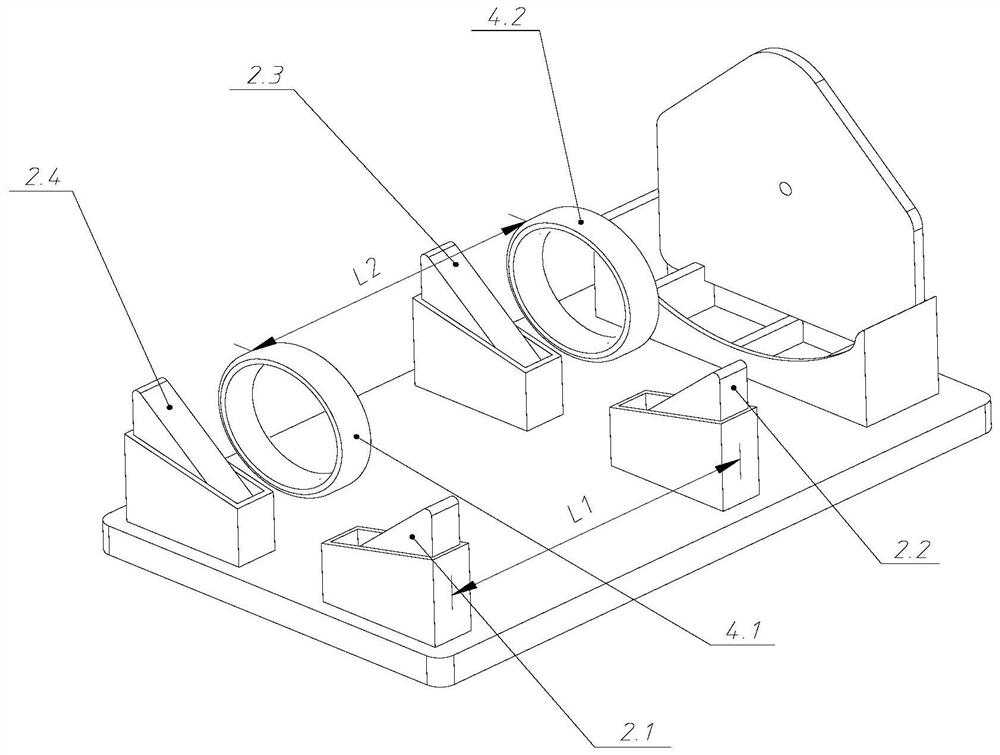

[0047] A multifunctional electret energy harvester composed of upper and lower external fixed components

[0048] Such as figure 2 As shown, it is a multi-functional electret energy harvester composed of upper and lower external fixed components, and the rest of the structural principle is the same as that of embodiment 1, and a triangular permanent magnet 2 of the same size is installed on the upper insulating substrate 3 , the polarity selection is the same as in Example 1. In this way, the two external fixed components can make the operation of the vibration pickup rotor assembly more stable. At the same time, because the two fixed substrate electrodes 8 output electric energy at the same time, the output electric energy is further increased, and the outer cylindrical surface of the vibration pickup rotor 5 is fully utilized. The electret thin film material makes it rotate in the same revolution and the power generation is twice that of Example 1.

Embodiment 3

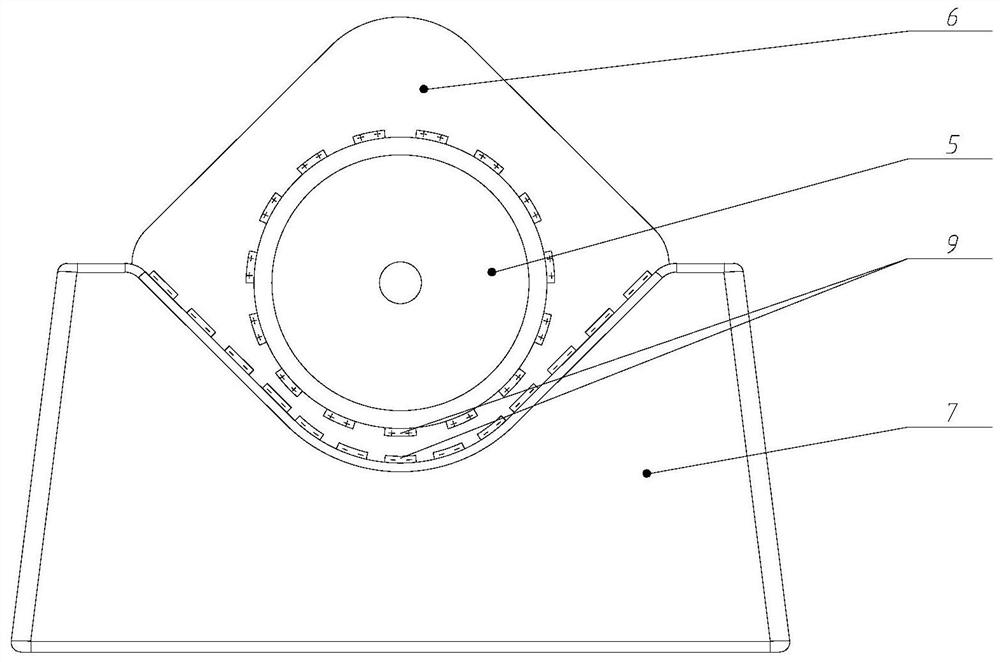

[0050] Such as image 3 As shown, in this example, the blade rotor 1 that bears wind force is replaced with blades that can receive wind and collect hydraulic energy, which further broadens the form of energy collection and expands the application occasions of the generator.

[0051] The hydraulic collecting blade 1 is composed of 6 bowl-shaped blades, the diameter of the part bearing the wind force is 16mm, and the length is 28mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com