Waterproof rubber jacketed flexible cable

A flexible cable and rubber sheath technology, applied in the field of rubber sheathed flexible cables, can solve the problems that rubber insulation or sheath is not waterproof, the service life of ordinary rubber sheathed cables is reduced, etc., and achieves excellent radial waterproof performance and overall structural arrangement. Reasonable and strong waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

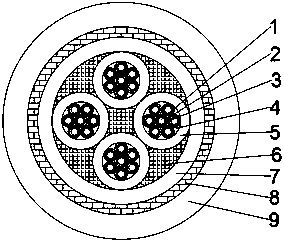

[0019] Such as figure 1 As shown, a kind of waterproof rubber-sheathed flexible cable according to the present invention includes a conductor monofilament 1, and a tin-plated layer 2 and a waterproof layer 3 are arranged outside the conductor monofilament 1, which form a conductor, at least two conductors Stranded, with waterproof filler I4 in the twisted gap, an insulating layer 5 is extruded outside the stranded conductor and waterproof filler I4, which form a core, at least two cables are twisted into a cable, and there is a cable in the twisted gap Waterproof filling II6, they form a cable core, an inner sheath 7 is extruded outside the cable core, a radial waterproof layer 8 is arranged outside the inner sheath 7, and a radial waterproof layer 8 is extruded outside the radial waterproof layer 8 There is an outer sheath 9; the conductor monofilamen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com