An optical device suitable for laser direct writing exposure equipment

An optical device and laser direct writing technology, applied in the field of optical systems, can solve problems such as low production capacity and processing, and achieve the effects of compact structure, convenient disassembly and installation, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

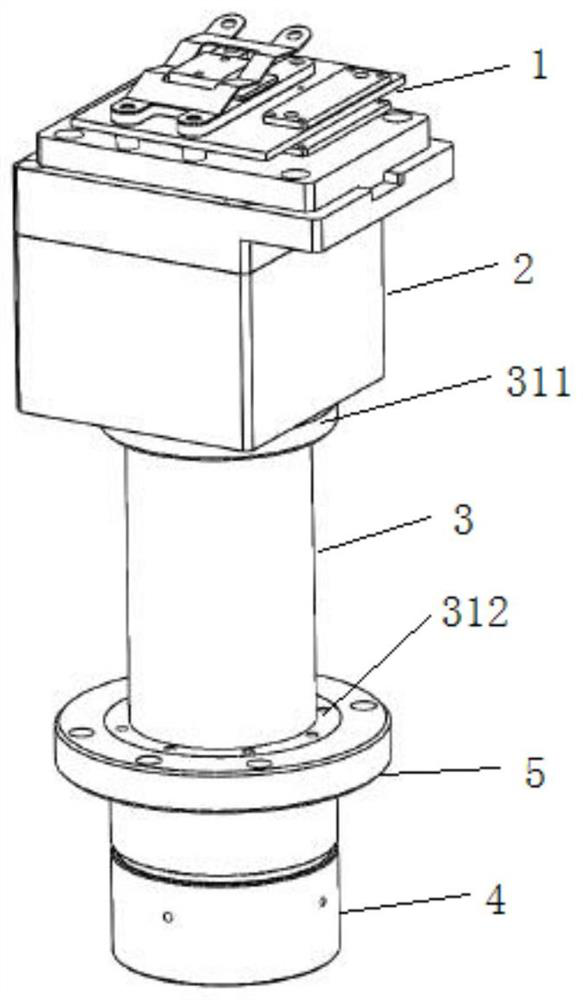

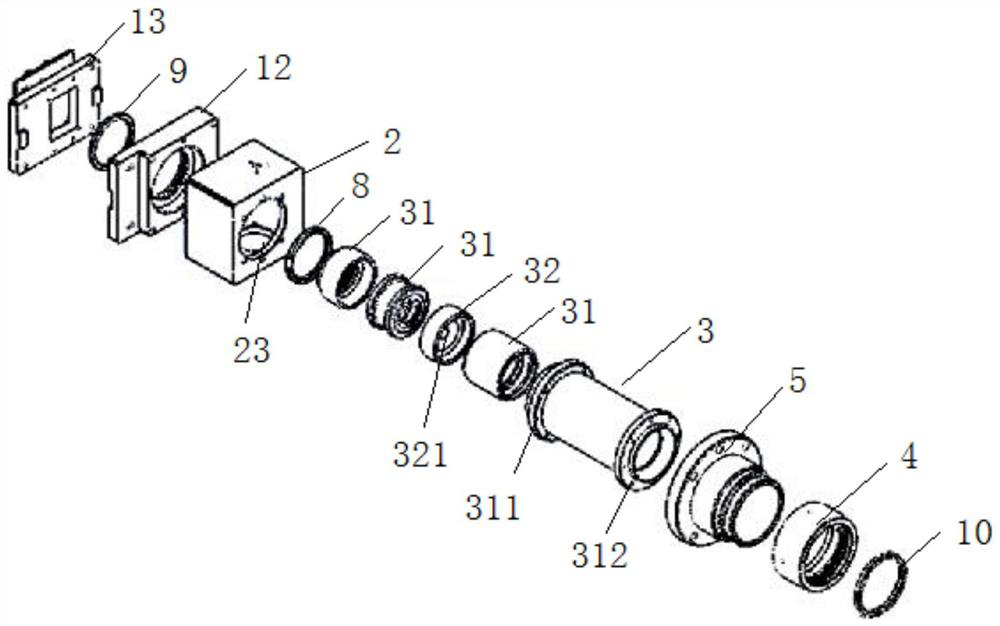

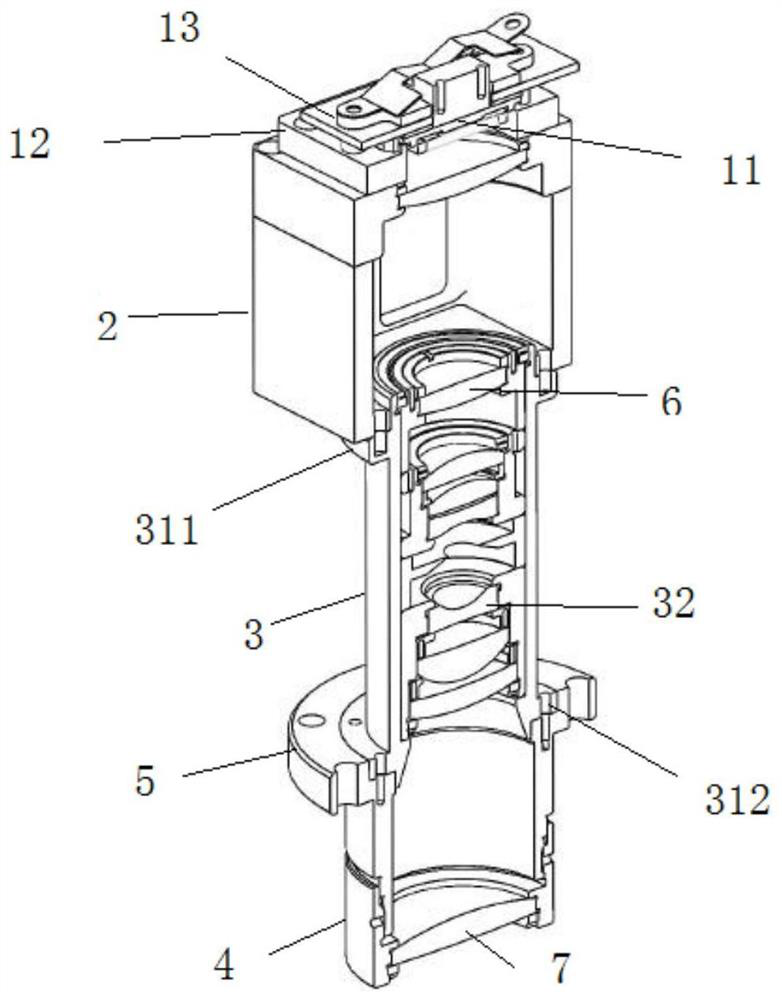

[0022] Such as Figure 1-4 As shown, the optical device suitable for laser direct writing exposure equipment in this embodiment includes an MLA assembly 1, an adapter seat 2, a lens assembly 3 and a magnification adjustment assembly 4. The MLA assembly 1 is installed on one end of the adapter seat 2, and the The other end of the socket 2 is fixedly connected to one end of the lens assembly 3 , and the other end of the lens assembly 3 is fixedly connected to the magnification adjustment assembly 4 . Various lenses are installed in the lens assembly 3 .

[0023] The MLA component 1 includes an MLA chip 11 , a fixing device 12 for fixing the MLA chip 11 and a cooling device 13 for dissipating heat from the MLA chip 11 . In actual use, the structure and size of the fixing device 12 can be set according to the adapter seat 2 , and a compression ring 9 is provided between the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com