Manual sample injector capable of controlling sample injection volume and sample injection method and application thereof

A technology of manual injection and injection volume, applied in chemical instruments and methods, laboratory containers, instruments, etc., can solve the problems of complex equipment and large volume, reduce volume and complexity, and increase convenience , The effect of preventing sample overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This example is used to illustrate the injection of a sample of known volume.

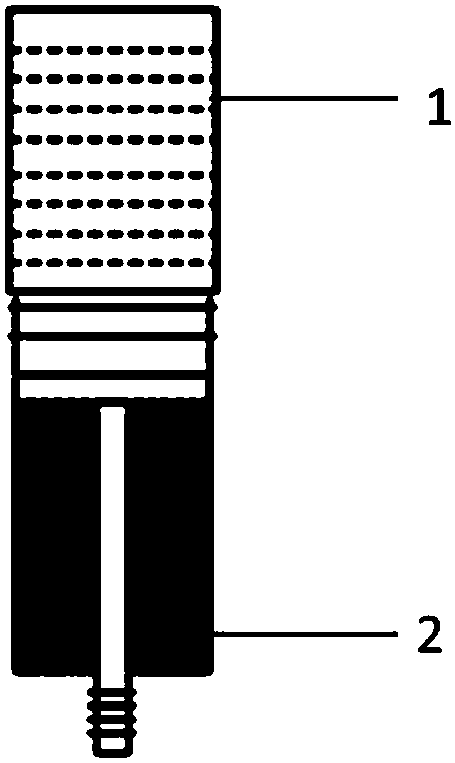

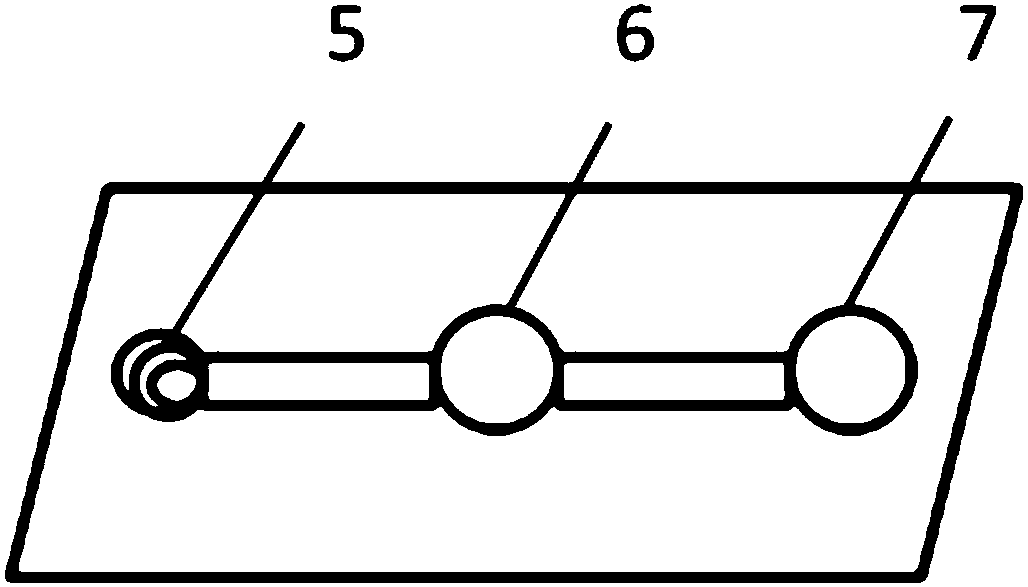

[0058] use as Figure 1-2 The manual sampler with controllable injection volume shown, the manual sampler includes a sample cell 2, a sample cell cover 1 and a sample outlet part 3; the sample cell cover 1 and the sample cell 2 are both cylindrical , transparent glass material, and detachably screwed to form a sleeve structure so as to seal and form a sample cavity with a volume of 100 μL. The sample outlet 3 is located on the opposite side of the sample cell 2 to the sample cell cover 1, through The movement of the sample cell cover 1 can change the volume of the sample chamber, and the sample in the sample chamber is pressed out through the sample outlet 3, the sample outlet 3 includes a straight tubular sample outlet channel 8, and one end of the sample outlet channel is The sample cell is connected, and the other end is used as a sample outlet, and an external thread is provided at the ...

Embodiment 2

[0063] This example is used to illustrate sample injection of unknown volume.

[0064] The same manual injector and microfluidic chip as in Example 1 were used.

[0065] Before starting the process, first add the sample into the manual injector, then seal the sample cell 2 with the sample cell cover 1, and make the lower end of the sample cell cover coincide with the 0 scale line of the sample cell. Then screw the external thread of the sample outlet 3 to the internal thread at the sampling port 5 of the microfluidic chip, so that the manual injector is connected to the microfluidic chip, and rotate the sample cell cover 1 to move the sample cell cover 1 downward. , the volume of the sample chamber decreases and the pressure increases. Under the action of the pressure, the sample enters the microfluidic chip through the sample outlet channel 8, observes the reading of the scale while injecting the sample, and stops when the sample cell cover coincides with the scale 2 of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com