Socket type self-returning multi-section prefabricated pier and assembly method thereof

An assembly method and self-resetting technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of reduced durability, hidden safety hazards, and high requirements for construction accuracy, and achieve the effect of avoiding high-altitude operations and enhancing durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

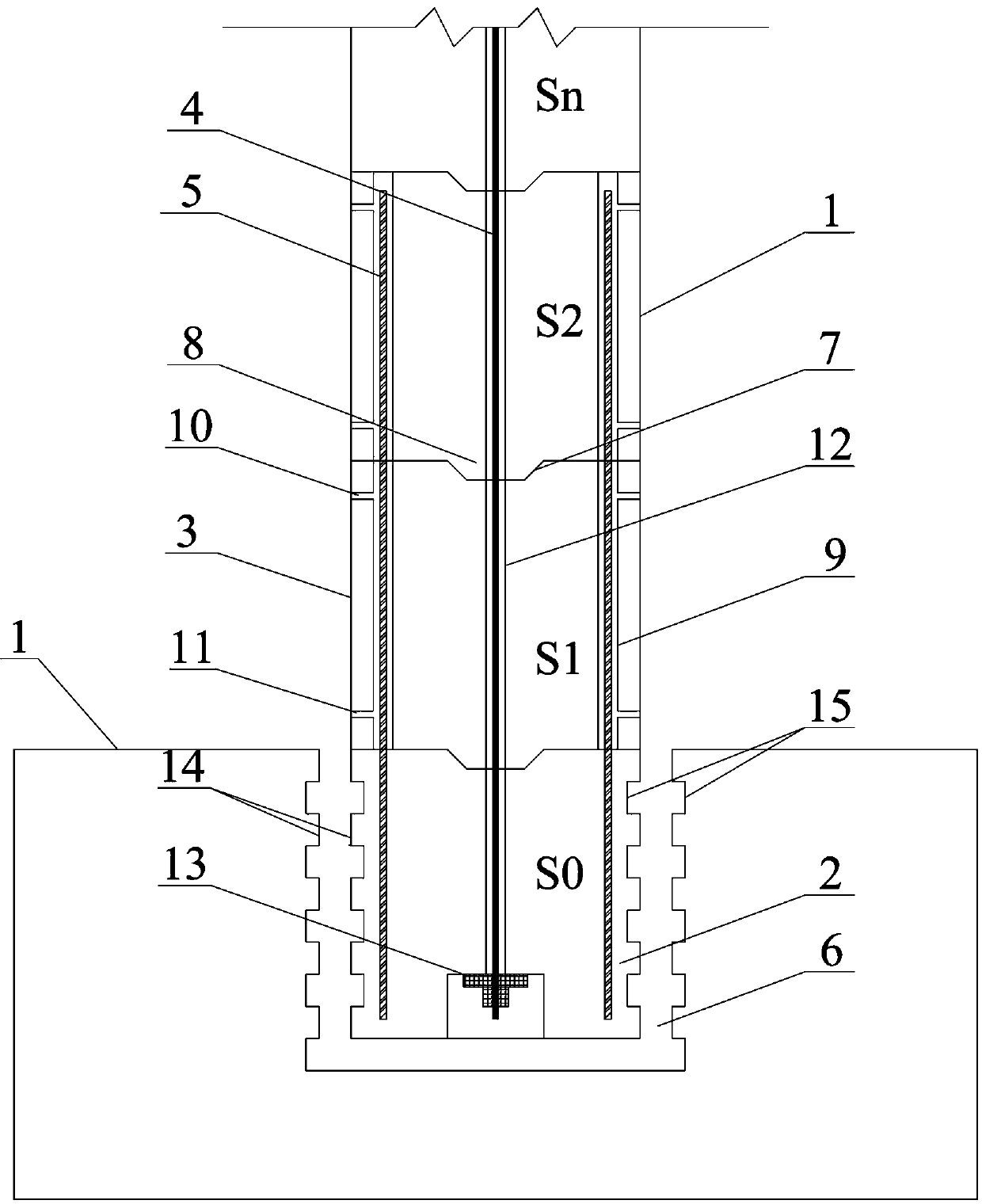

[0026] Such as figure 1 As shown, a socket-type self-resetting multi-segment prefabricated pier includes a cap 1 and a prefabricated pier. energy muscle 5;

[0027] The pier installation hole 6 is set in the vertical direction of the cap 1, the prefabricated pier is inserted into the pier installation hole 6 through the insertion cap segment 2, and a plurality of the pier body segments 3 are stacked installed on the insertion cap segment 2;

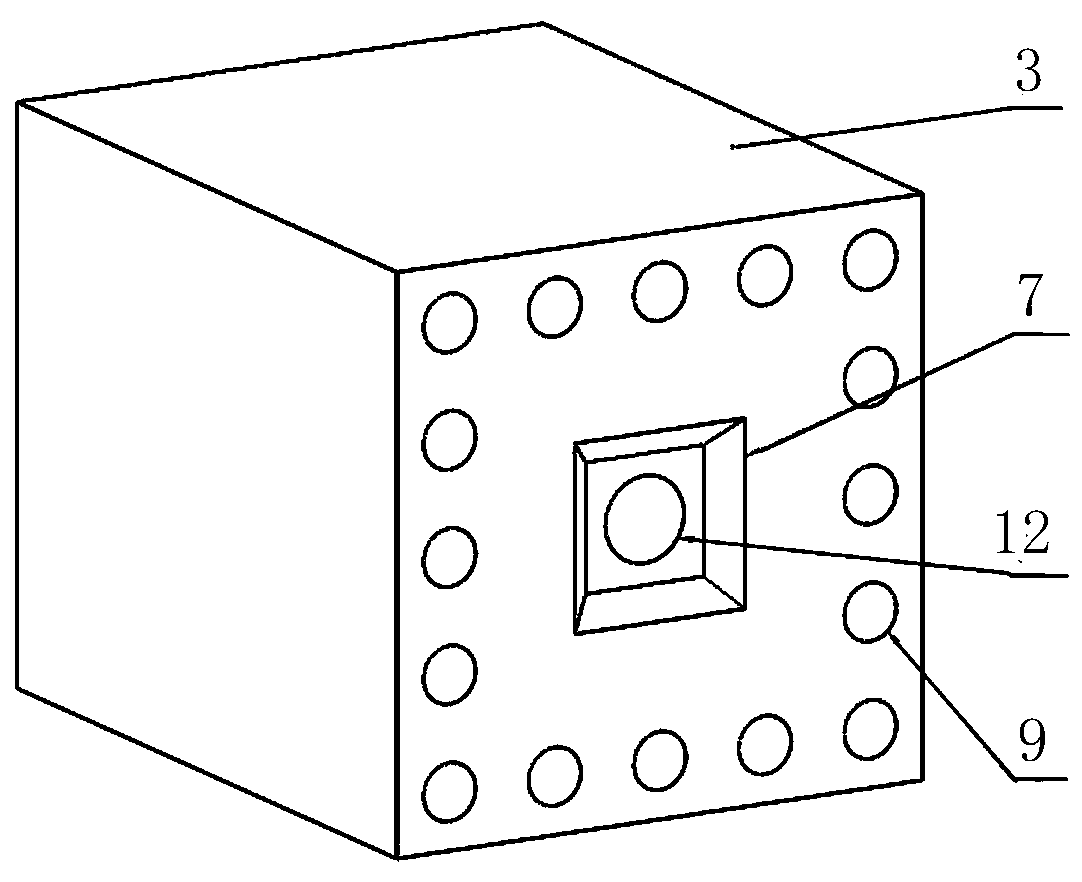

[0028] The top surface of the insertion cap segment 2 and the top surface of the pier body segment 3 are provided with a shear key groove I7, and the bottom of the pier body segment 3 is provided with a shear key I8. The size of the force key I8 is adapted to the shear key groove I7;

[0029] The prefabricated pier is provided with a pier grouting sleeve 9 for embedding energy dissipation tendons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com