A safety interlocking device and control method for electrode connection platform of lf refining furnace

A technology of safety interlocking and electrodes, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve problems such as personal and equipment accidents, safety hazards, electrode arcing, etc., to achieve reasonable device structure, avoid personal and equipment accidents, and control The method is simple and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

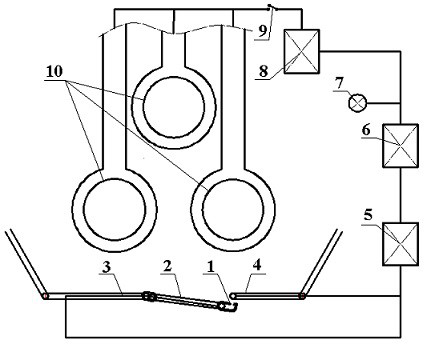

[0012] A safety interlocking device for an LF refining furnace connected to an electrode platform, including an electrode isolation door lock 1, an electrode isolation door 2, an electrode isolation fence 3, a signal transmission line 4, an interlocking device PLC control cabinet 5, a computer 6, an indicator light 7, and an electrode PLC control Cabinet 8, power switch 9, three-phase electrodes 10; the isolation door 2 is installed on the isolation fence 3, and the isolation fence 3 is provided with a signal transmission line 4, and the electrode isolation door lock 1 is installed on the isolation door 2, and is isolated from one end The column 3 matches; the two ends of the electrode isolation door lock 1 are respectively connected to the signal transmission line 4 in the isolation column 3, the signal transmission line 4 is connected to the interlocking device PLC control cabinet 5, the interlocking device PLC control cabinet 5 is connected to the computer 6, and the computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com