Anaerobic digestion device for enhancing biogas production by utilizing self-sustaining air floatation

A technology for anaerobic digestion and biogas production, which is used in biochemical cleaning devices, enzymology/microbiology devices, gas production bioreactors, etc. , to avoid insufficient degradation, high degree of automation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

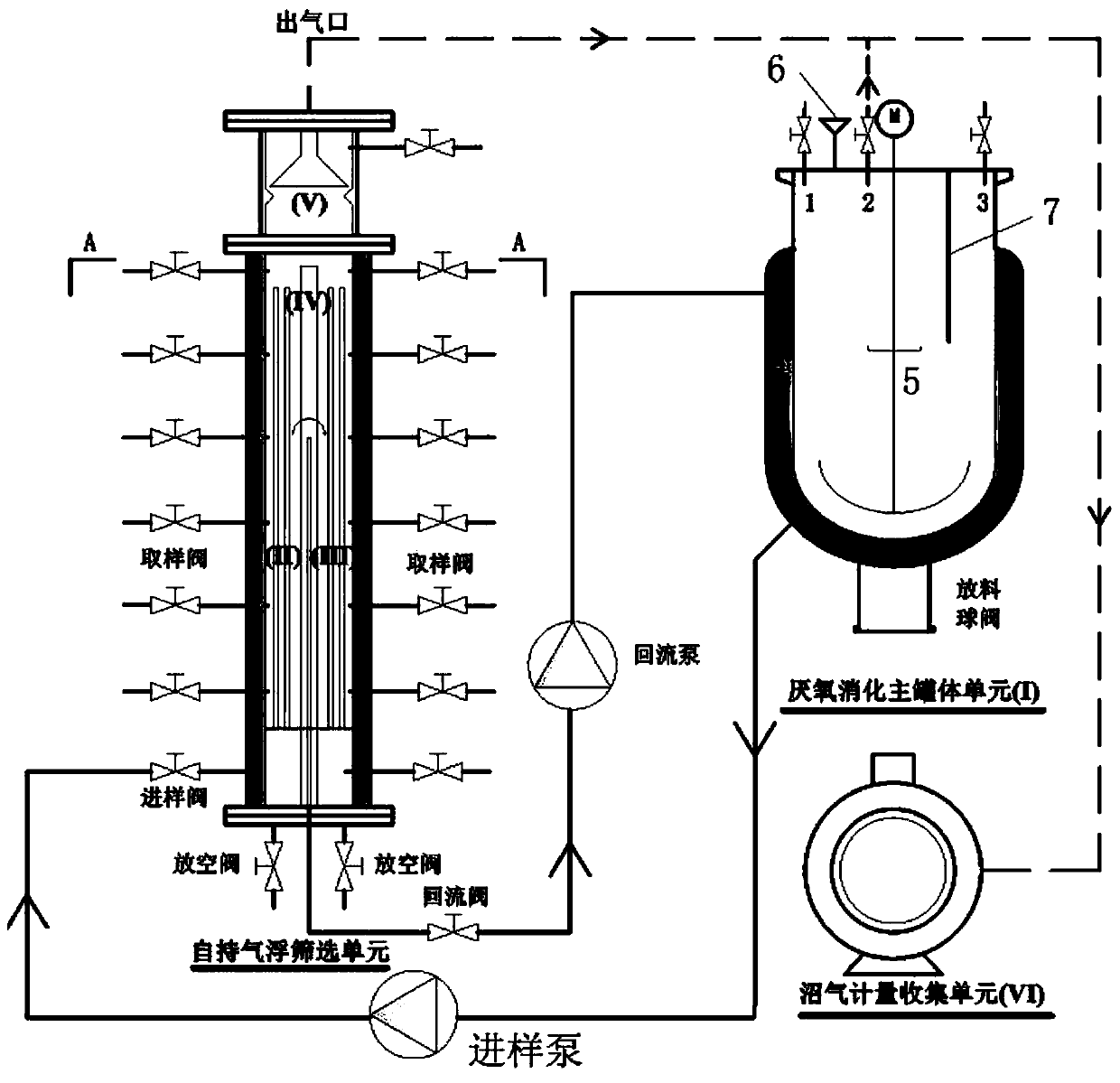

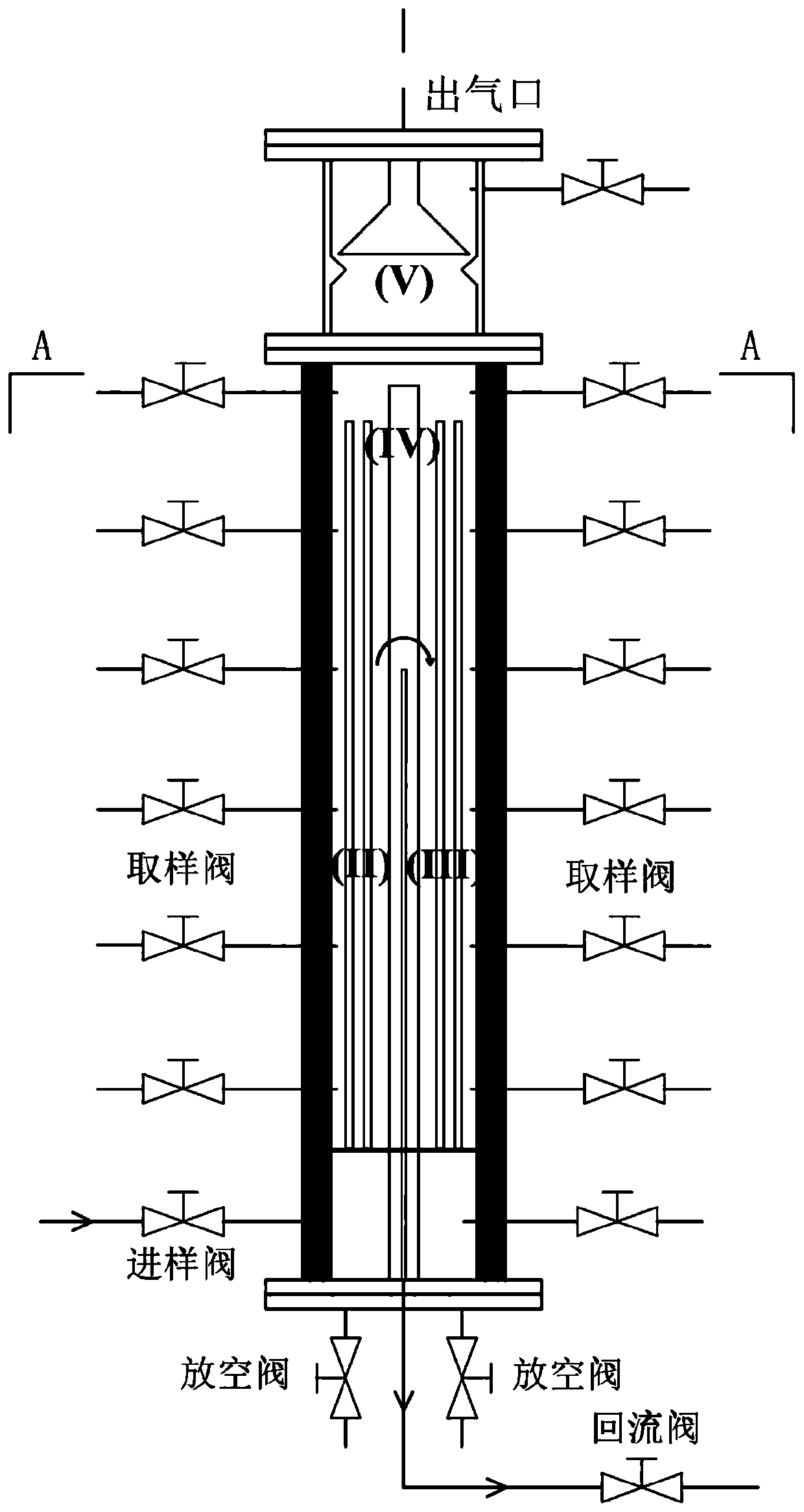

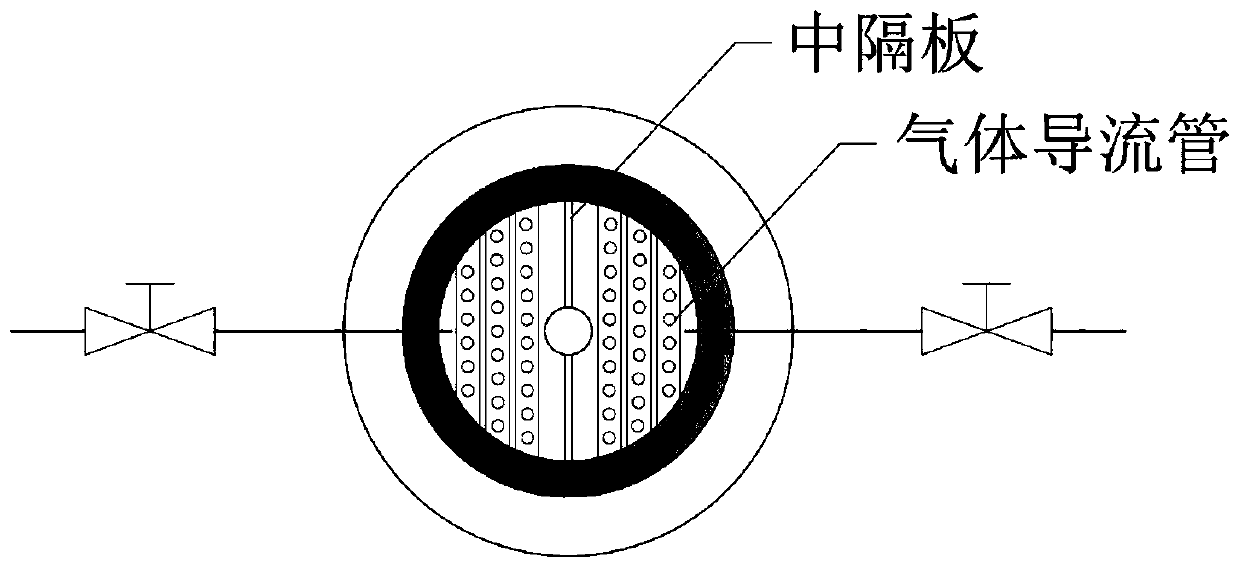

[0038] Such as figure 1 As shown, the anaerobic digestion device using self-sustained air flotation to strengthen biogas production in this embodiment includes anaerobic digestion main tank unit I, self-sustained air flotation screening unit and biogas metering, taking the fully mixed anaerobic reactor (CSTR) as an example The collection unit VI, wherein the self-sustaining air flotation screening unit is a four-part integrated type, specifically includes the air flotation screening part II, the material sedimentation part III, the active reflux part IV and the three-phase separation part V. The digested material in the anaerobic digestion main tank unit I is municipal sludge, which is pumped into the air flotation screening part II by the peristaltic sampling pump. The air flotation screening unit continuously feeds materials, and the light and highly active microorganisms are screened through the air flotation screening part II and the material sedimentation part III, and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com