Insulation structure of fermentation tank for warm room biogas preparation

A fermentation tank and warm room technology, applied in the field of thermal insulation structure of fermentation tanks for biogas production in greenhouses, can solve problems such as inability to produce gas, low gas production, and inability to meet winter heat preservation requirements, and achieve strong practicability, simple structure, and guaranteed yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

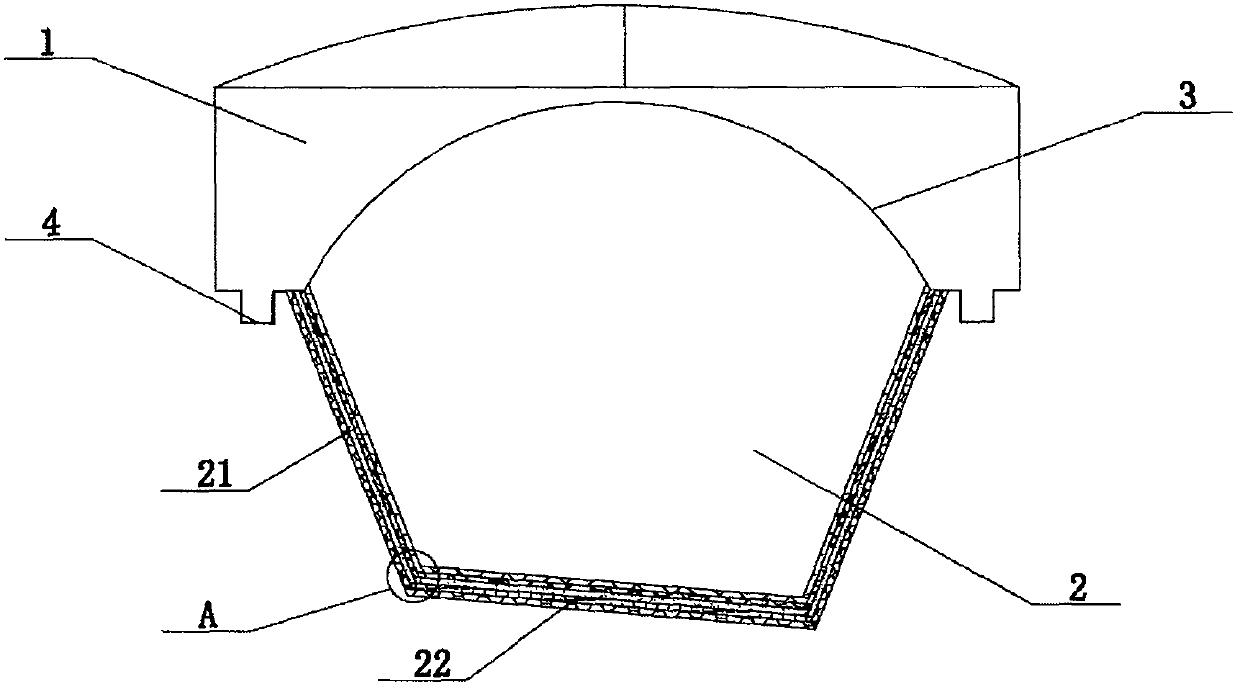

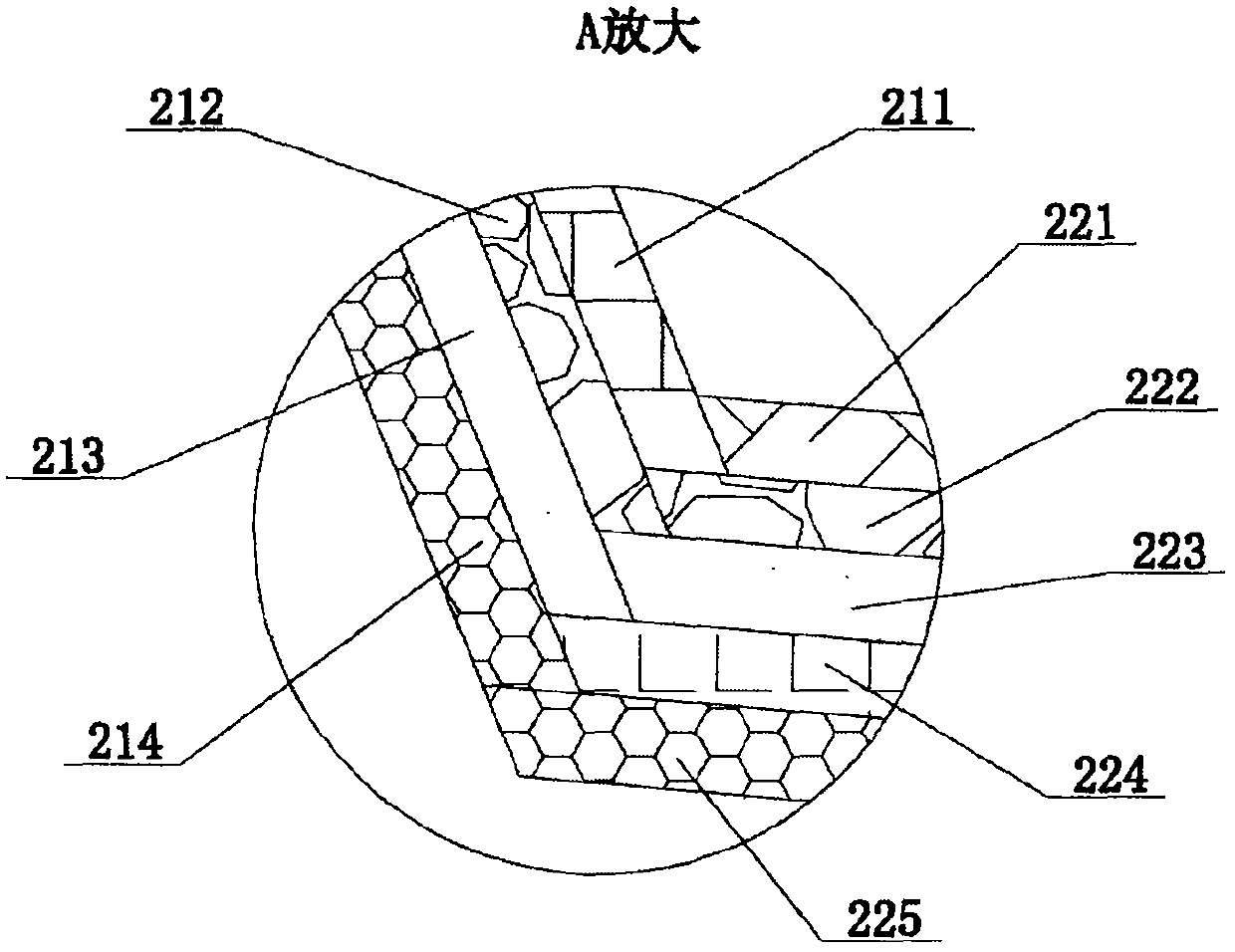

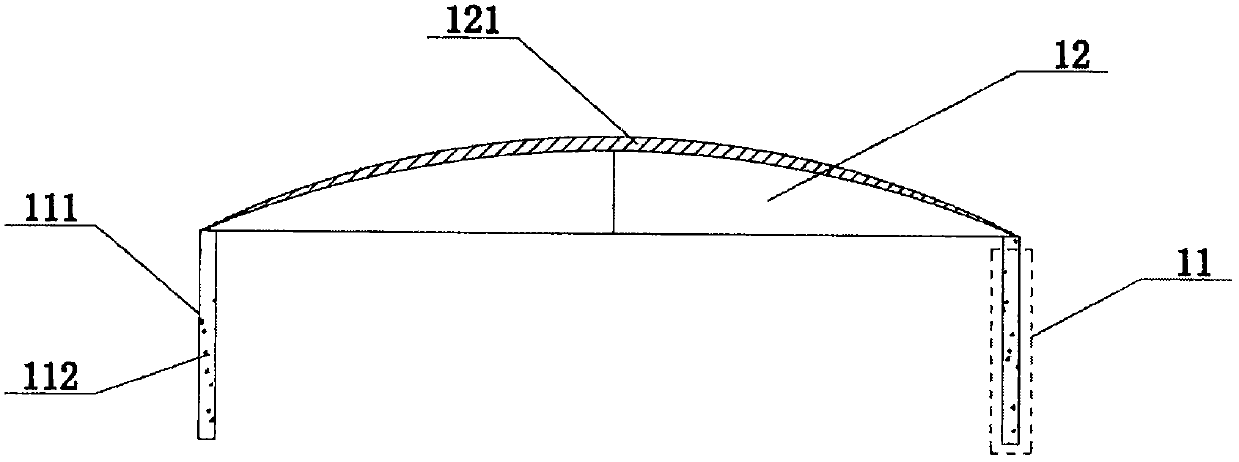

[0021] see Figure 1-Figure 3 As shown, the technical solution adopted in this specific embodiment is: it includes a warm room 1, a fermentation tank 2, and an HDPE film 3. The warm room 1 wraps the fermentation tank 2 inside, and the fermentation tank 2 includes a pool wall 21 , pool bottom 22, described pool wall 21, pool bottom 22 form cross-section to be trapezoidal structure, described HDPE film 3 is arranged on the pool wall 21 of fermentation tank 2, pool bottom 22 and upper opening and forms airtight structure, described The pool wall 21 comprises a first thermal insulation layer 211, a concrete layer 212, a second thermal insulation layer 213, and a first cushion layer 214, and the first thermal insulation layer 211, the concrete layer 212, the second thermal insulation layer 213, and the first cushion layer 214 are composed of Set up in sequence from inside to outside, the pool bottom 22 includes a third insulation layer 221, a concrete layer 222, a fourth insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com