ZSM-5 molecular sieve and preparation method thereof

A ZSM-5, molecular sieve technology, applied in nanotechnology, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of low product yield, high raw material cost, long synthesis cycle, etc. High, low cost of raw materials, short synthesis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

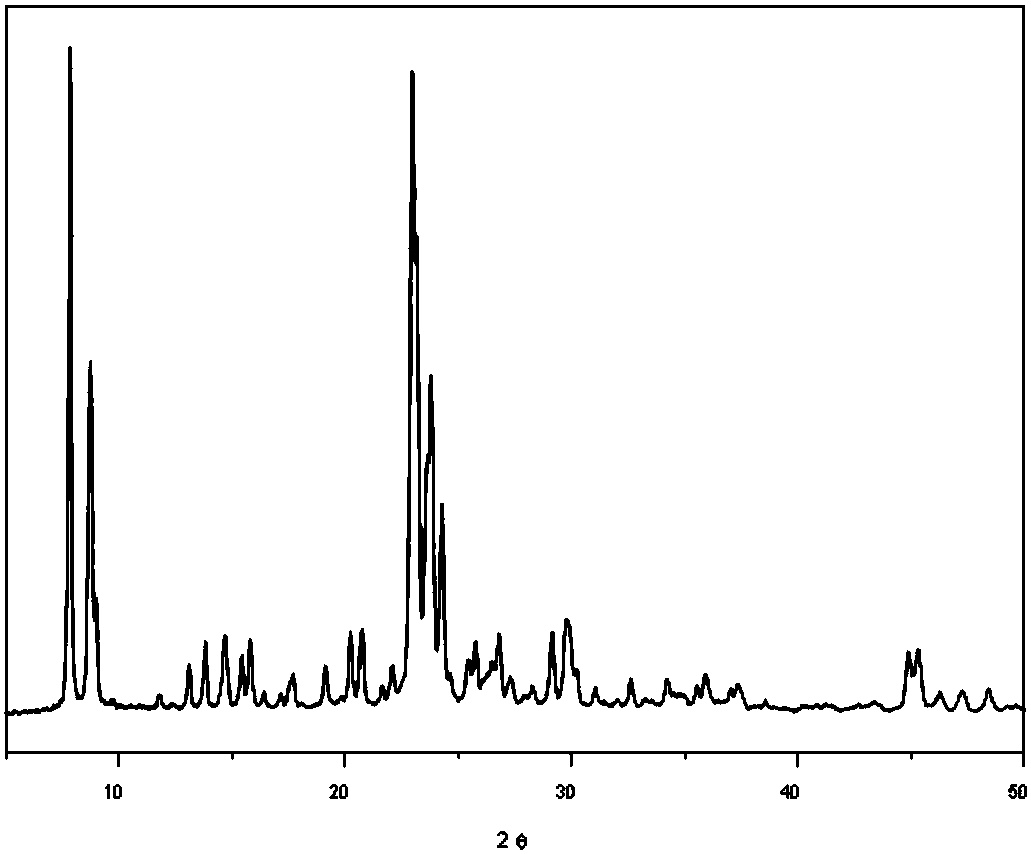

[0045] Raw material ratio is SiO 2 :Al 2 o 3 :n-Butylamine:Na 2 O:H 2 O=1:0.02:0.13:0.06:10. According to the ratio of raw materials, add 23.60g of sodium metaaluminate, 15.18g of sodium hydroxide and 166.57g of deionized water into the stainless steel crystallization kettle and stir evenly, then add 45.56g of n-butylamine and stir evenly, and finally add 300g of silica gel particles and seal the crystallization After stirring and crystallizing at 110°C for 35 hours, the remaining 666.27g of deionized water was added to the crystallization kettle through a metering pump, and then the crystallization temperature was raised to 170°C to continue crystallization for 20 hours. The product was washed, dried, and Roasting, ion exchange obtain final product, and this product has the characteristic diffraction peak of ZSM-5 through XRD characterization (see image 3 ), the SEM picture shows that the crystal grains of the ZSM-5 molecular sieve are around 150nm (see Figure 4 ).

Embodiment 2

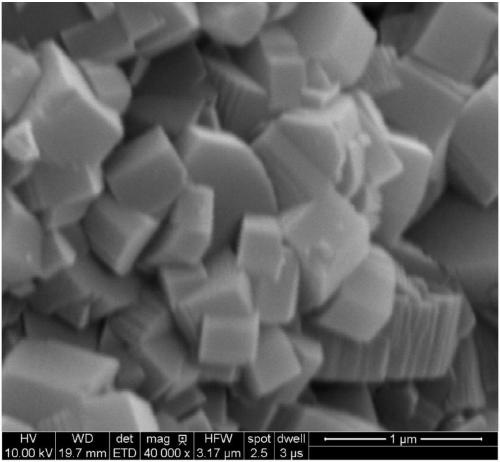

[0047] Raw material ratio is SiO 2 :Al 2 o 3 :n-Butylamine:Na 2 O:H 2 O=1:0.01:0.25:0.10:12. According to the ratio of raw materials, add 10.22g of sodium metaaluminate, 29.60g of sodium hydroxide and 261.82g of deionized water into the stainless steel crystallization kettle and stir evenly, then add 75.93g of n-butylamine and stir evenly, and finally add 260g of silica gel particles and seal the crystal After stirring and crystallizing at 110°C for 40 hours, the remaining 610.91 g of deionized water was added to the crystallization kettle through a metering pump, and then the crystallization temperature was raised to 160°C to continue crystallization for 25 hours. The product was washed, dried, and Roasting, ion exchange obtain final product, and this product has the characteristic diffraction peak of ZSM-5 through XRD characterization (see Figure 5 ), the SEM picture shows that the grains of the ZSM-5 molecular sieve are between 100 and 300nm (see Image 6 ).

Embodiment 3

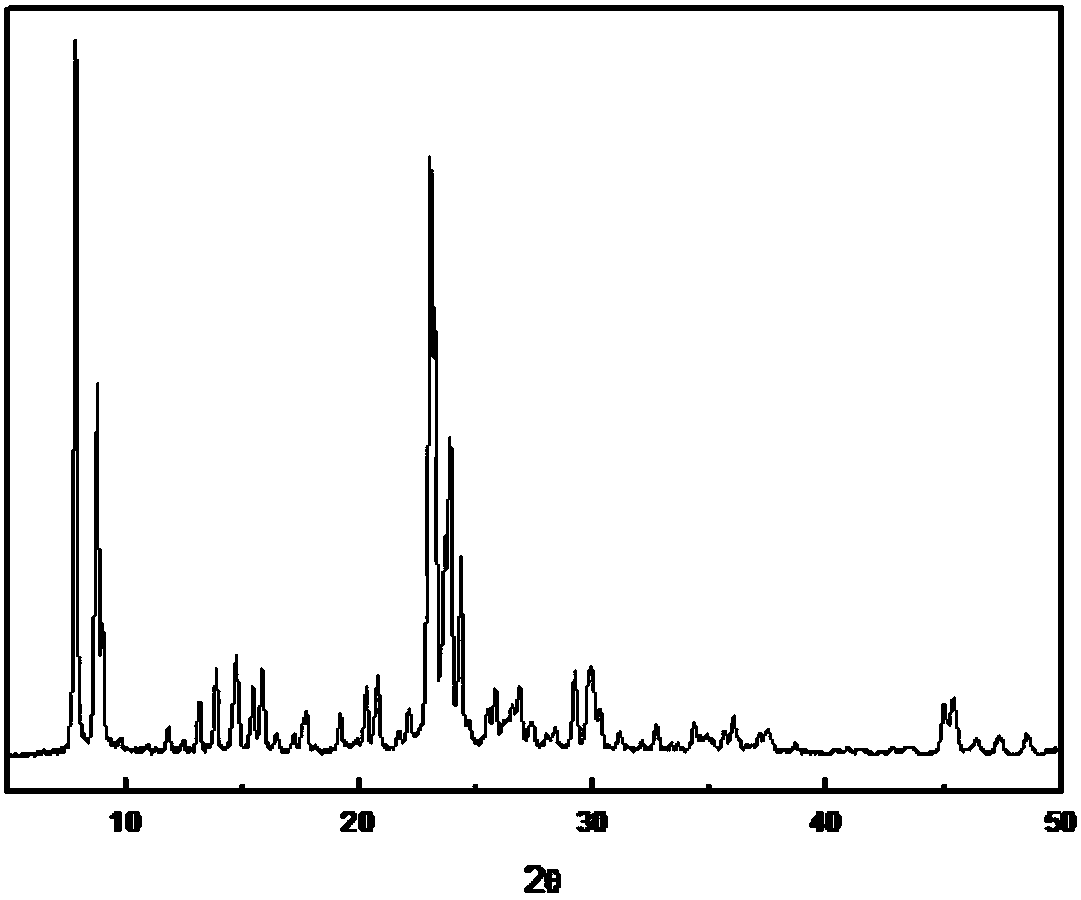

[0049] Raw material ratio is SiO 2 :Al 2 o 3 :n-Butylamine:Na 2 O:H 2 O=1:0.006:0.360:0.120:15. Add 6.60g of sodium metaaluminate, 40.38g of sodium hydroxide and 472.25g of deionized water into the stainless steel crystallization kettle according to the ratio of raw materials and stir evenly, then add 117.77g of n-butylamine and stir evenly, and finally add 280.05g of silica gel particles and seal Crystallization kettle, after stirring and crystallizing at 110°C for 50h, add the remaining 708.37g of deionized water into the crystallization kettle through a metering pump, and then raise the crystallization temperature to 170°C to continue crystallization for 15h, and the product is washed and dried , roasting, and ion exchange to obtain the final product, which has the characteristic diffraction peak of ZSM-5 through XRD (see Figure 7 ), the SEM picture shows that the grains of the ZSM-5 molecular sieve are between 100 and 200nm (see Figure 8 )

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com