Method for processing stable and reliable roll gap measuring signals of aluminum alloy cold rolling

A processing method and technology for measuring signals, applied in rolling force/roll gap control, metal rolling, metal rolling, etc., can solve the problems of weakened signal anti-interference ability, poor aluminum plate shape, roll inclination, etc. The effect of avoiding equipment accidents and product quality accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

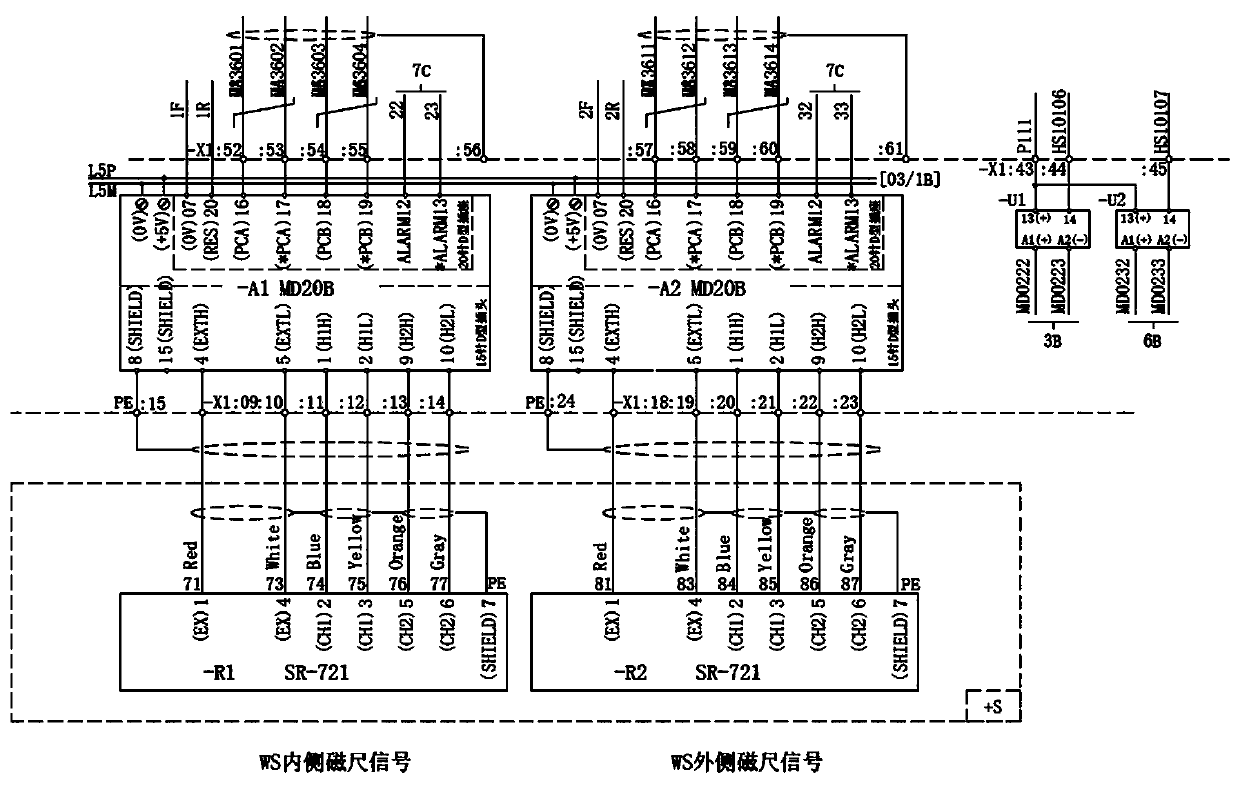

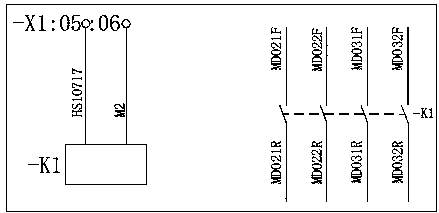

[0024] Such as Figure 1-2 As shown, a method for processing a stable and reliable roll gap measurement signal for cold rolling of aluminum alloy is used to convert the alarm signal sent by the roll gap signal sensor through a transmitter into an alarm signal during the cold rolling of aluminum alloy. Access to the switch signal S of the automation control system; the automation control system judges the switch signal S to filter false alarms, and evaluates whether the roll gap signal sensor is stuck or whether the sensor signal has excessive deviation.

[0025] The transmitter is an MD20B transmitter; the roll gap signal sensor is a magnetic ruler of the hydraulic roll gap control system of a rolling mill;

[0026] The processing method includes the following aspects:

[0027] Step A1. Automatically filter and reset the MD20B instant alarm according to the switch signal S, so that the magnetic scale signal can truly reflect the size of the roll gap in real time;

[0028] Step A2: De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com