Cobalt zinc bimetallic sulfide based composite electrocatalyst, and preparation method and applications thereof

An electrocatalyst and bimetallic technology, applied in the field of electrocatalysis, can solve the problems of less surface active sites and reduced specific surface area, and achieve outstanding stability, increased specific surface area, and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

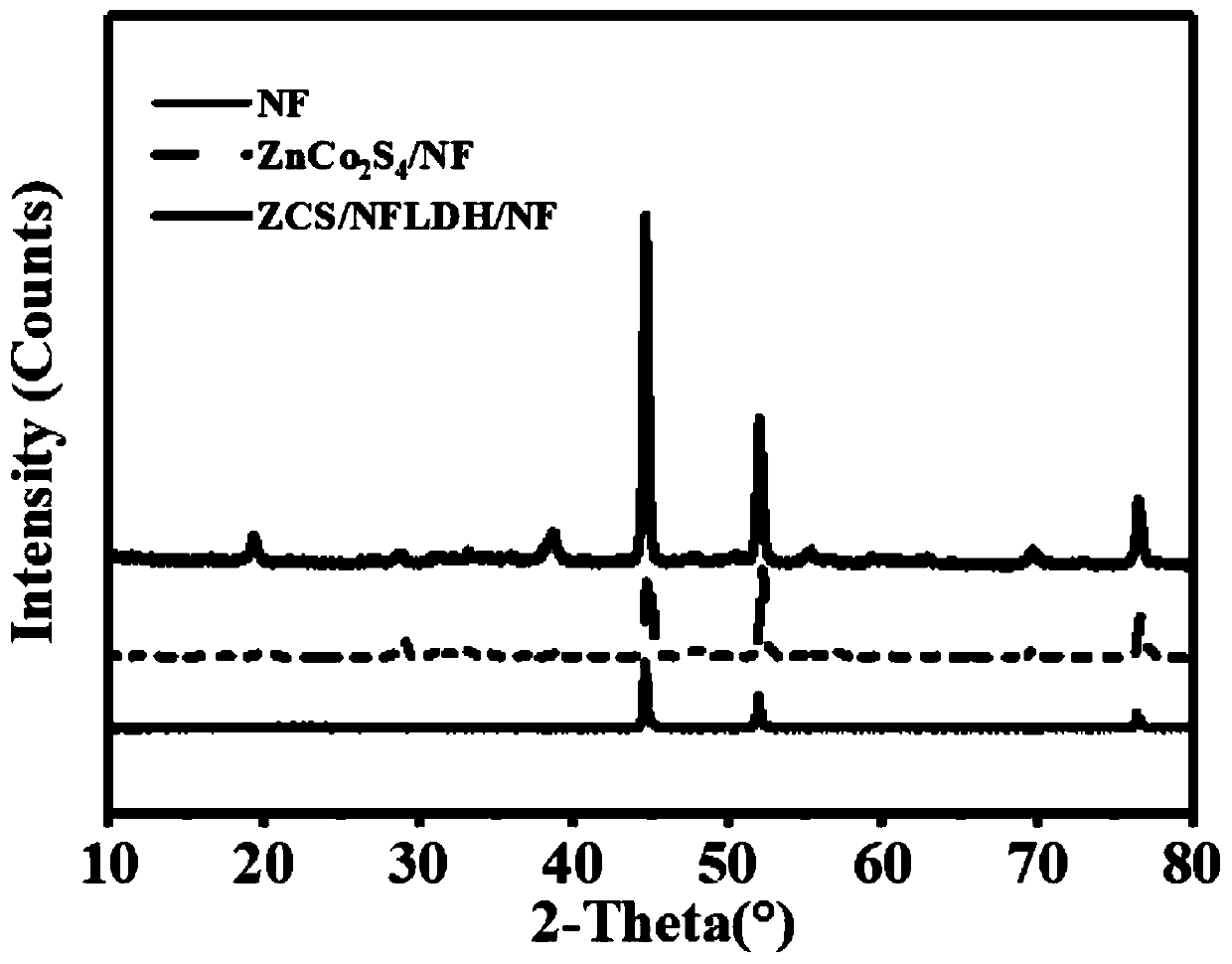

[0031]Preparation of cobalt-zinc bimetallic sulfide / nickel-iron layered double hydroxide / nickel foam electrocatalyst (ZCS / NFLDH / NF) based on nickel foam (NF):

[0032] (1) The cut nickel foam was ultrasonically cleaned with 3M hydrochloric acid, deionized water, acetone and ethanol in sequence for 30 minutes, and then vacuum-dried at 60° C. for 12 hours.

[0033] (2) Weigh 1mmol Zn(NO 3 ) 2 ·6H 2 O, 2mmol Co(NO 3 ) 2 ·6H 2 O, 2 mmol NH 4 F and 5mmol urea, add 35mL deionized water, stir for 5 minutes to a clear solution; put 2cm×5cm foam nickel into the solution, transfer to a 50mL reaction kettle, 120°C hydrothermal reaction for 5h, after the reaction is over; take out the foam Nickel A, washed with water and alcohol, dried at 60°C for 12h.

[0034] Weigh 0.3g Na 2 S·9H 2 O, add 60ml of deionized water, stir for 10min to a clear solution, add the above-mentioned nickel foam A, transfer the solution to a 100mL reactor, and conduct a hydrothermal reaction at 180°C for 6...

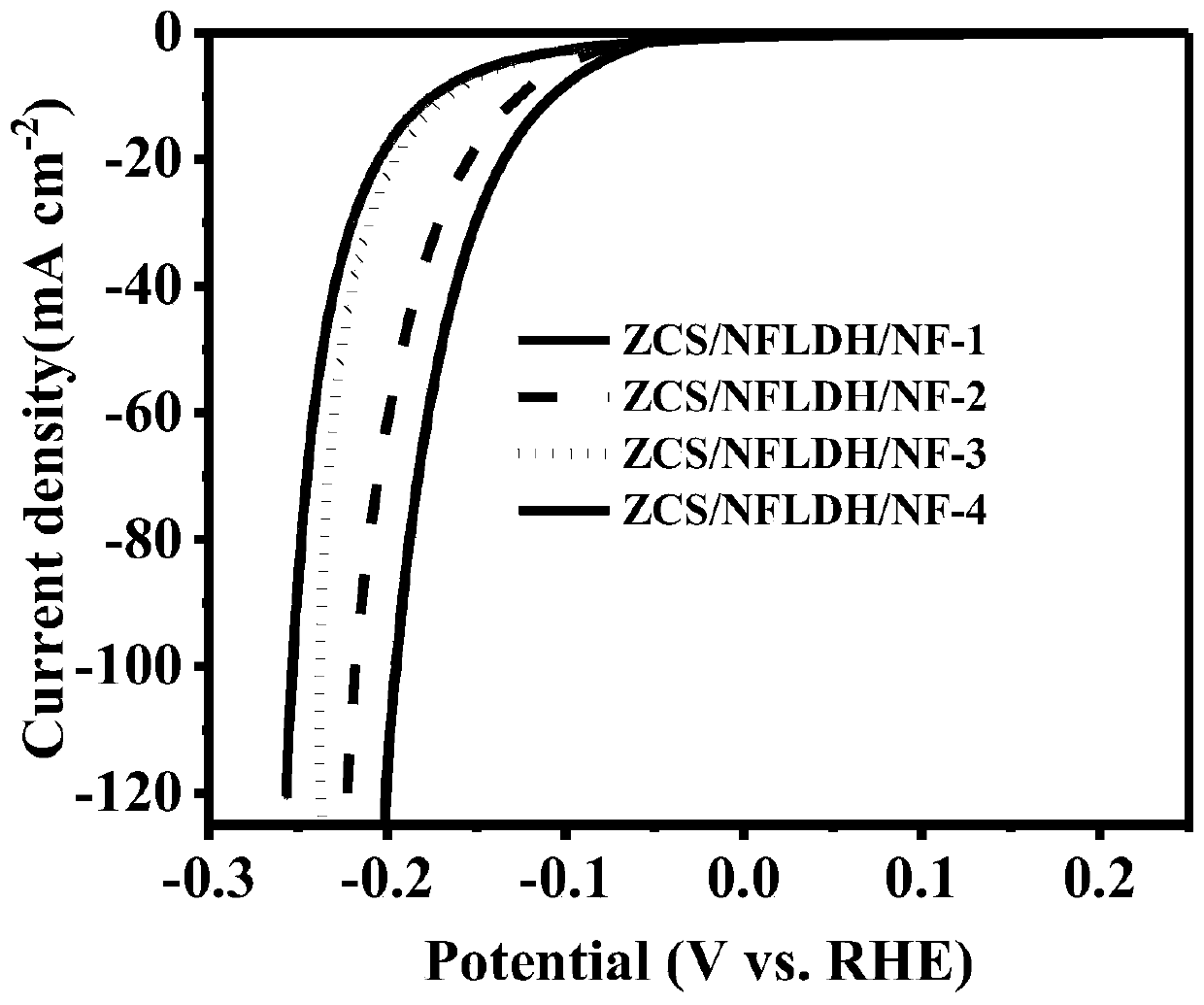

Embodiment 2

[0037] The preparation method of the electrocatalytic material is basically the same as in Example 1, except that the hydrothermal time in step (3) is changed to 36 h. The rest of the conditions remain unchanged. The material is named ZCS / NFLDH / NF-2.

Embodiment 3

[0039] The preparation method of the electrocatalytic material is basically the same as that of Example 1, the difference is that the Ni(NO 3 ) 3 9H 2 O was changed to 6 mmol. The rest of the conditions remain unchanged. The material is named ZCS / NFLDH / NF-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com