Bean-based pudding and manufacturing method thereof

A soy-based pudding and pudding technology, applied in the field of vegetable protein products, can solve the problems of not being able to meet the requirements of normal temperature storage and transportation, not adopting sterilization treatment, easy to be spoiled and deteriorated, etc., and achieve suitable for large-scale production and application, good flavor, and excellent flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

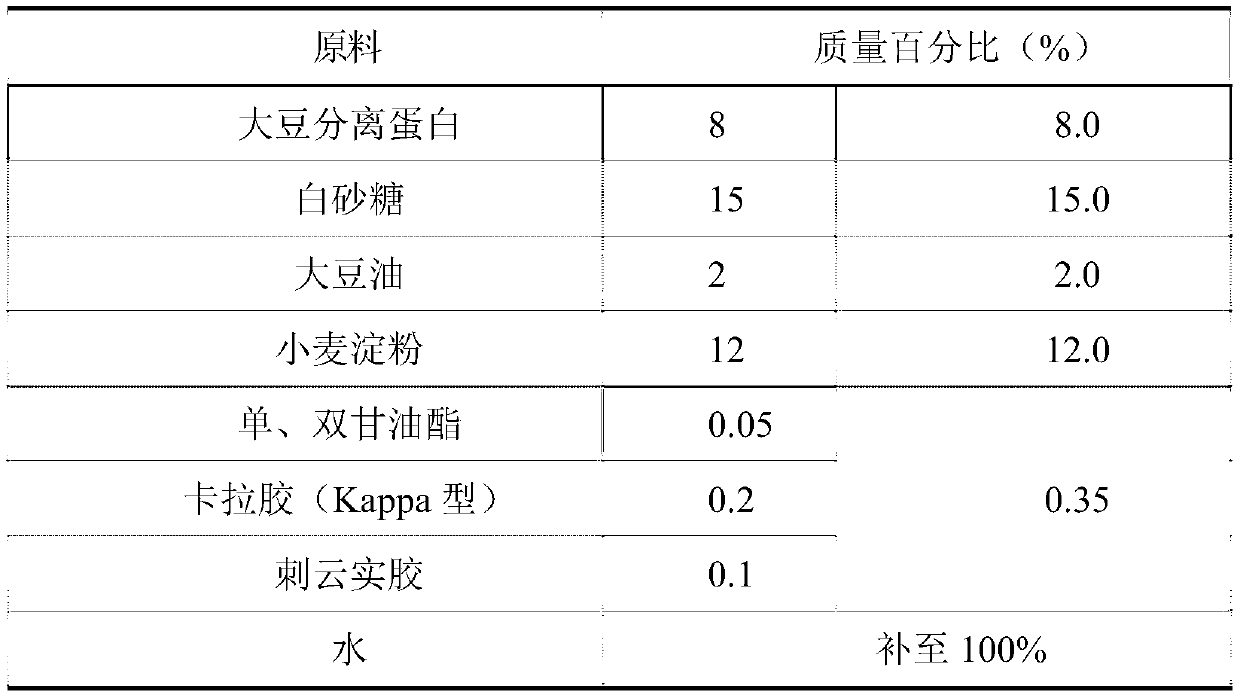

[0032] A recipe for soy-based pudding is shown in Table 1:

[0033] Table 1

[0034]

[0035] The preparation method of described soybean-based pudding comprises the following steps:

[0036] (1) Heat water to 25°C, slowly add soybean protein isolate, keep warm and stir for 30 minutes, and mix evenly to obtain mixed liquid A.

[0037] (2) Mix the mixed solution A with white granulated sugar, soybean oil, wheat starch, mono- and diglycerides, carrageenan (Kappa type), and tara gum at a mixing temperature of 25°C, and keep stirring for 30 minutes to obtain the mixed solution B .

[0038] (3) Homogenize the mixed liquid B, the homogenization condition is 15MPa, 65°C.

[0039] (4) Ultra-high temperature instantaneous sterilization of the mixed liquid obtained by homogenizing in step (3), the sterilization condition is 138° C., 4 s.

[0040] (5) Cool the mixed solution sterilized in step (4) to 50° C., then fill it, and seal it within 10 seconds after filling.

Embodiment 2

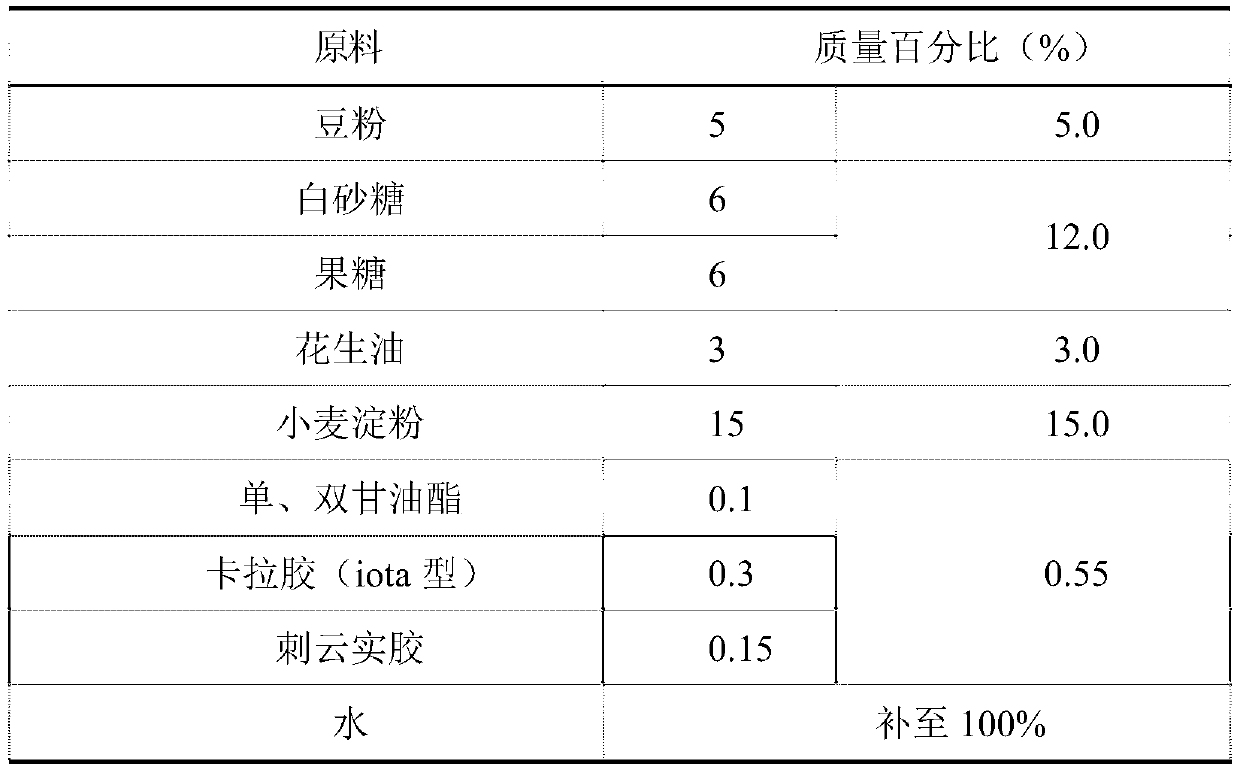

[0042] A recipe for soy-based pudding is shown in Table 2:

[0043] Table 2

[0044]

[0045] The preparation method of described soybean-based pudding comprises the following steps:

[0046] (1) Heat the water to 40°C, slowly add soybean powder, keep stirring for 20 minutes, and mix well to obtain the mixed solution A.

[0047] (2) Mix the mixed solution A with white granulated sugar, fructose, peanut oil, wheat starch, mono- and diglycerides, carrageenan (iota type), and tara gum, at a mixing temperature of 40°C, and keep stirring for 20 minutes to obtain a mixed solution b.

[0048] (3) Homogenize the mixed liquid B, the homogenization condition is 18MPa, 60°C.

[0049] (4) Sterilize the homogenized mixed solution obtained in step (3), and the sterilization condition is 139° C. for 3 s.

[0050] (5) Cool the mixed solution sterilized in step (4) to 40° C., then fill it, and seal it within 10 seconds after filling.

Embodiment 3

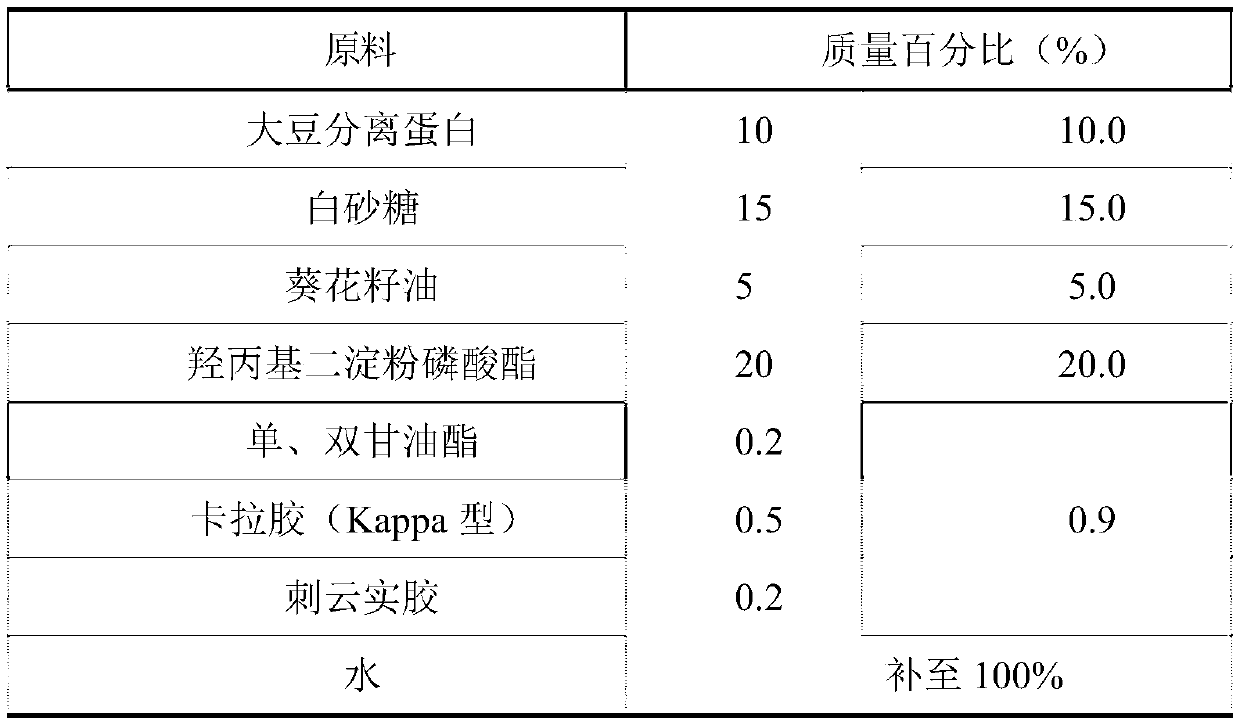

[0052] A recipe for soy-based pudding is shown in Table 3:

[0053] table 3

[0054]

[0055] The preparation method of described soybean-based pudding comprises the following steps:

[0056] (1) Heat water to 60°C, slowly add soybean protein isolate, keep warm and stir for 15 minutes, and mix well to obtain mixed solution A.

[0057] (2) Mix the mixed liquid A with white granulated sugar, sunflower oil, hydroxypropyl distarch phosphate, mono- and diglycerides, carrageenan ((Kappa type), tara gum, the mixing temperature is 60°C, and keep warm Stir for 15 min to obtain mixed solution B.

[0058] (3) Homogenize the mixed liquid B, the homogenization condition is 22MPa, 55°C.

[0059] (4) Sterilize the homogenized mixed solution obtained in step (3), and the sterilization condition is 140° C. for 3 s.

[0060] (5) Cool the mixed solution sterilized in step (4) to 60° C., then fill it, and seal it within 10 seconds after filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com