Low-temperature plasma generator and method for preparing activated water

A low-temperature plasma and generating device technology, applied in the field of plasma, can solve the problems of easy damage, low preparation efficiency, limited plasma water volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

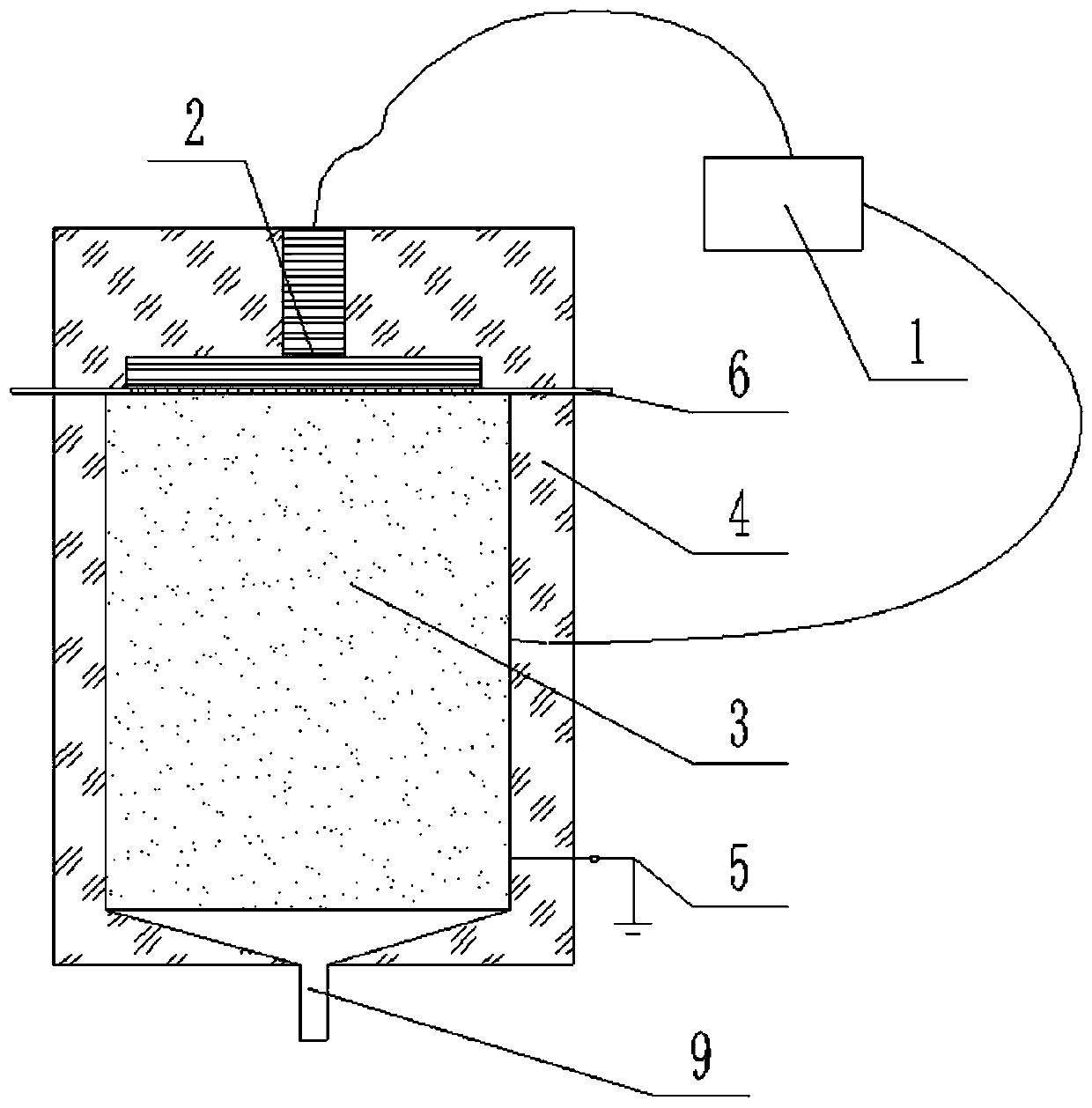

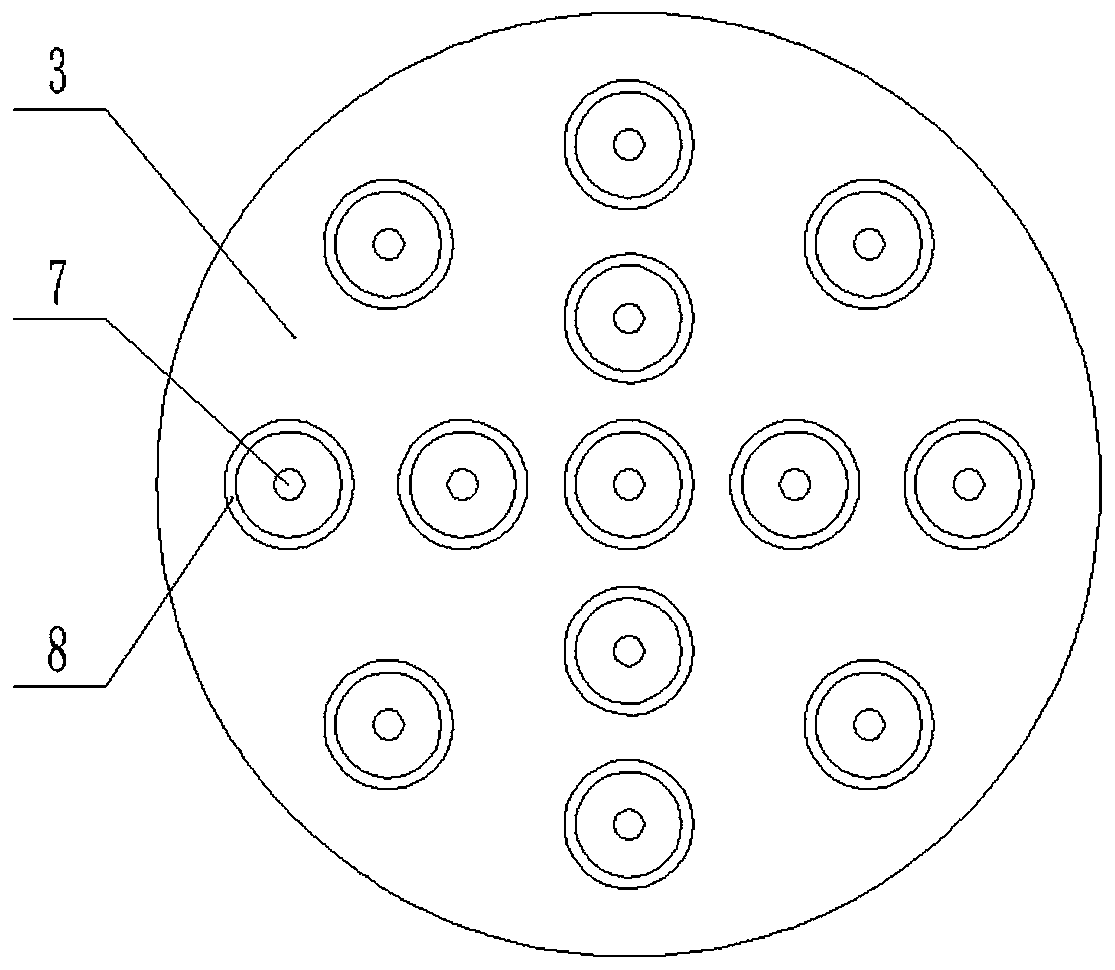

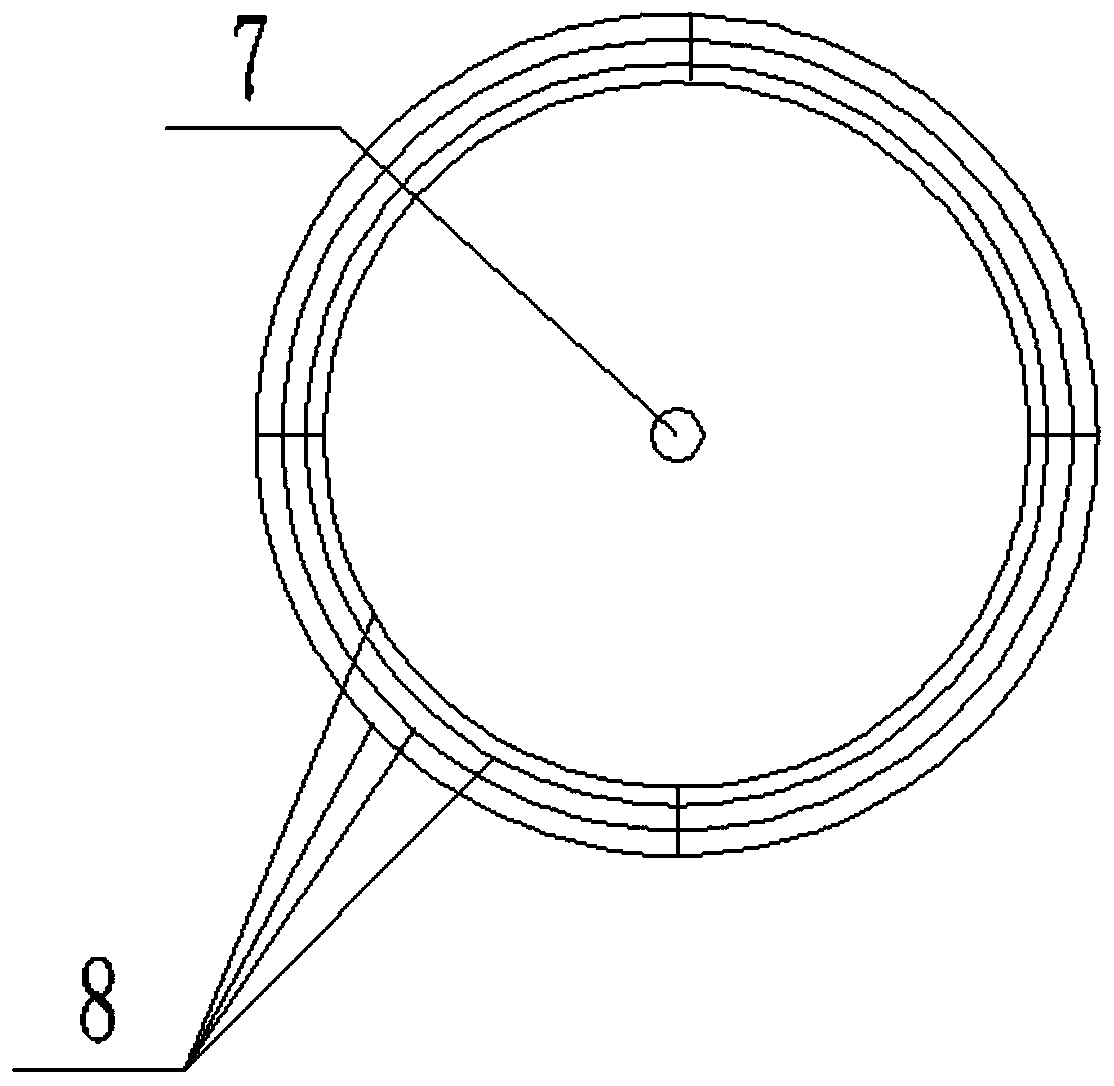

[0042] A low-temperature plasma generating device, including a power supply, an insulating container, and a plasma generating mechanism arranged inside the insulating container; the plasma generating mechanism includes an electrode array plate, a porous electrode column, and a barrier medium tube; the electrode array plate and The high-voltage output end of the power supply is connected, and the porous electrode column is connected to the low-voltage input end of the power supply and grounded through a ground wire;

[0043] The electrode array plate includes a connection plate and an electrode column array group composed of high-voltage electrode columns arranged at the bottom of the connection plate; through holes suitable for high-voltage electrode columns are distributed in the porous electrode columns, and the through holes A barrier medium pipe is arranged between the hole and the high-voltage electrode column; at least two inlet holes for loading working gas are arranged ...

Embodiment 2

[0053] A low-temperature plasma generating device, including a power supply, an insulating container, and a plasma generating mechanism arranged inside the insulating container; the plasma generating mechanism includes an electrode array plate, a porous electrode column, and a barrier medium tube; the electrode array plate and The high-voltage output end of the power supply is connected, and the porous electrode column is connected to the low-voltage input end of the power supply and grounded through a ground wire;

[0054] The electrode array plate includes a connection plate and an electrode column array group composed of high-voltage electrode columns arranged at the bottom of the connection plate; through holes suitable for high-voltage electrode columns are distributed in the porous electrode columns, and the through holes A barrier medium pipe is arranged between the hole and the high-voltage electrode column; at least two inlet holes for loading working gas are arranged ...

Embodiment 3

[0064] A low-temperature plasma generating device, including a power supply, an insulating container, and a plasma generating mechanism arranged inside the insulating container; the plasma generating mechanism includes an electrode array plate, a porous electrode column, and a barrier medium tube; the electrode array plate and The high-voltage output end of the power supply is connected, and the porous electrode column is connected to the low-voltage input end of the power supply and grounded through a ground wire;

[0065] The electrode array plate includes a connection plate and an electrode column array group composed of high-voltage electrode columns arranged at the bottom of the connection plate; through holes suitable for high-voltage electrode columns are distributed in the porous electrode columns, and the through holes A barrier medium pipe is arranged between the hole and the high-voltage electrode column; at least two inlet holes for loading working gas are arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com