Pneumatic guide device for lifting of reactor internals as well as assembling use method thereof

A technology of guiding devices and internal components, applied in the direction of reactor fuel elements, reactors, reducing greenhouse gases, etc., can solve the problems of insufficient length, increase the time of the main line, manpower and material resources, and cannot be hoisted by the top cover of the pressure vessel, so as to reduce radiation exposure The effect of reducing the dose, shortening the hoisting period, and simplifying the maintenance workflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

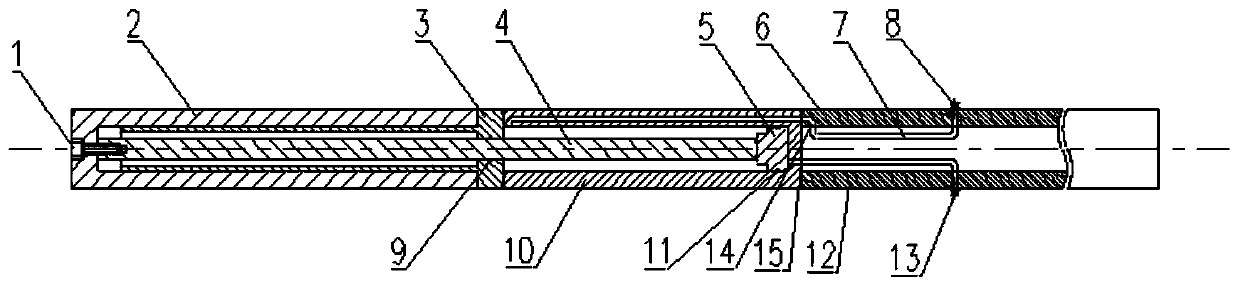

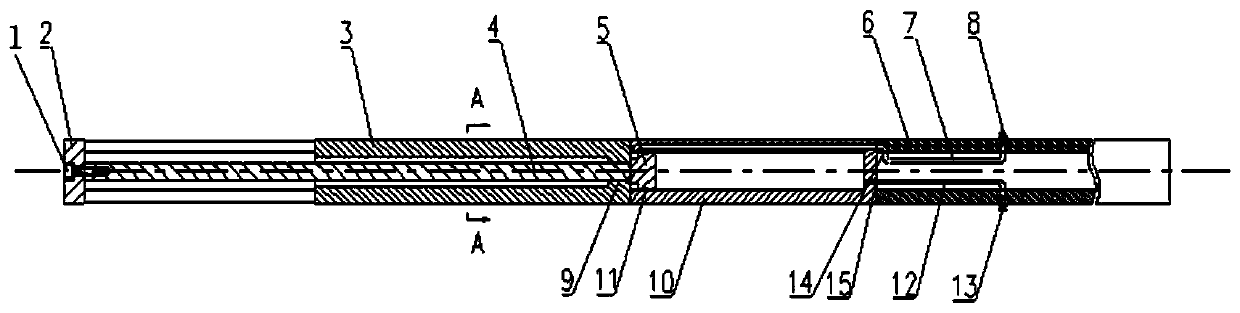

[0044] A pneumatic guiding device for hoisting internal components of a reactor pressure vessel, such as figure 1 As shown, it includes fixing screw 1, which is located on the top of the device and is used to connect the telescopic head 2 and the piston rod 4;

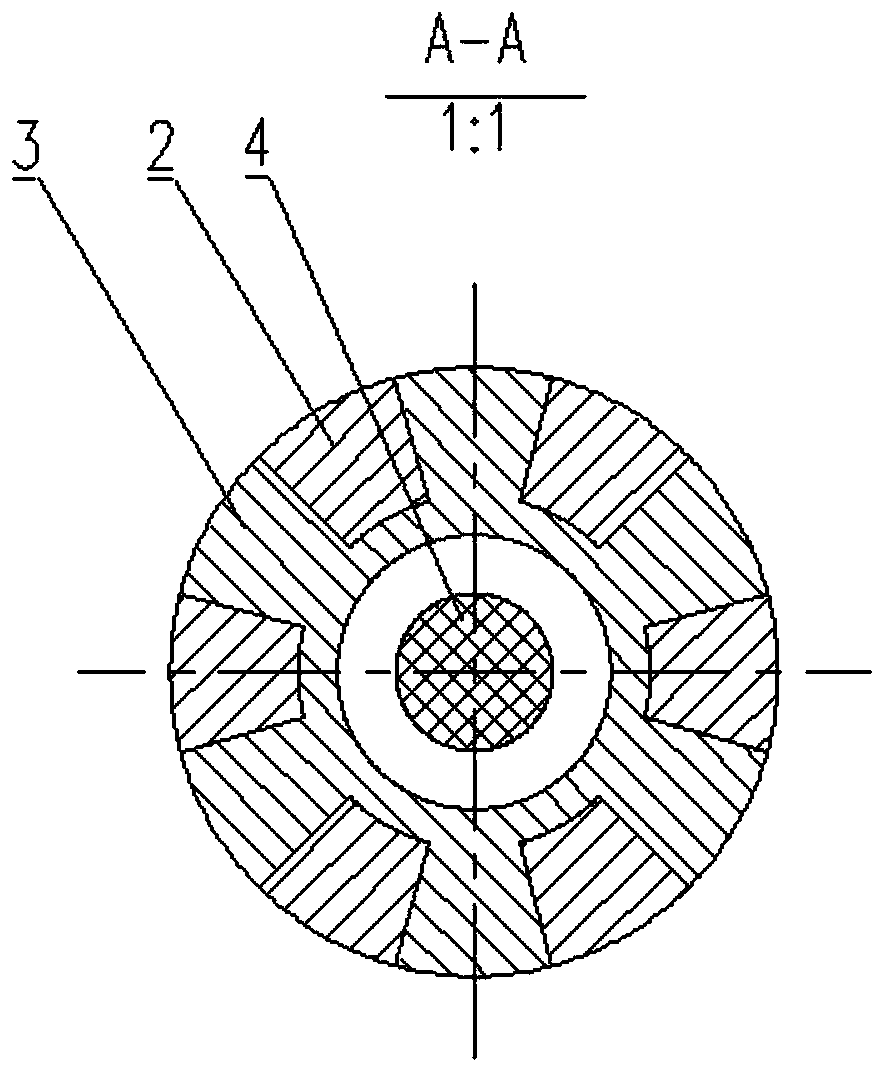

[0045] The telescopic head 2 is placed outside the fixed column 3 of the telescopic head, and the telescopic head 2 slides radially with the fixed column 3 of the telescopic head under the action of the piston rod 4. The cross-section of the mating surface is as follows: figure 2 shown;

[0046] The bottom of the telescopic head fixing column 3 is welded to the top of the cylinder 10, and the bottom of the cylinder 10 is welded to the top of the guide rod seat 6;

[0047] The lower part of the piston rod 4 is welded to the piston 5, and the piston 5 is placed inside the cylinder 10;

[0048] The upper part of the intake pipe 7 is welded with the cylinder air inlet 14 of the guide rod seat 6, and the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com