A self-sealing pressure test joint

A self-sealing and pressure testing technology, applied in the direction of pipe/pipe joint/fitting, sleeve/socket connection, using liquid/vacuum degree for liquid tightness measurement, etc., it can solve the problem of pressure test joint or pipe damage, pipe bending and sealing parts damage etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

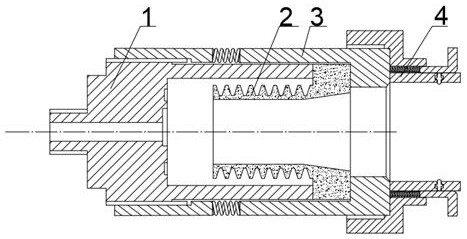

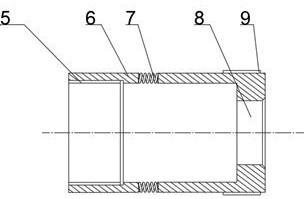

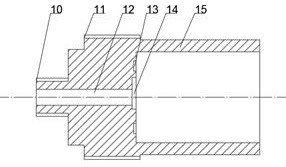

[0028] Such as figure 1 As shown, a self-sealing pressure test joint includes a sleeve 3, the bottom of the sleeve 3 is provided with a through hole 8, the sealing gasket 2 is arranged on the inner side of the bottom of the sleeve 3, and the inner side of the sleeve 3 A sleeve internal thread 5 is provided, and a terminal external thread 11 is provided on the outside of the terminal 1, and the sleeve 3 and the terminal 1 are connected through the sleeve internal thread 5 and the terminal external thread 11, so One end of the end head 1 is connected to the sealing gasket 2, the diameter of the through pipe hole 8 is larger than the opening of the sealing gasket 2, and it also includes a clamping centering device 4, and the outer side of the bottom of the sleeve 3 passes through the external thread 9 of the sleeve. Connect with clamping centering device 4.

[0029] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com