A modular structure for convenient laying of floor heating pipelines

A technology of modular structure and floor heating pipes, applied in lighting and heating equipment, hot water central heating systems, heating methods, etc. The effect of fast paving, strengthening bearing strength and improving paving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

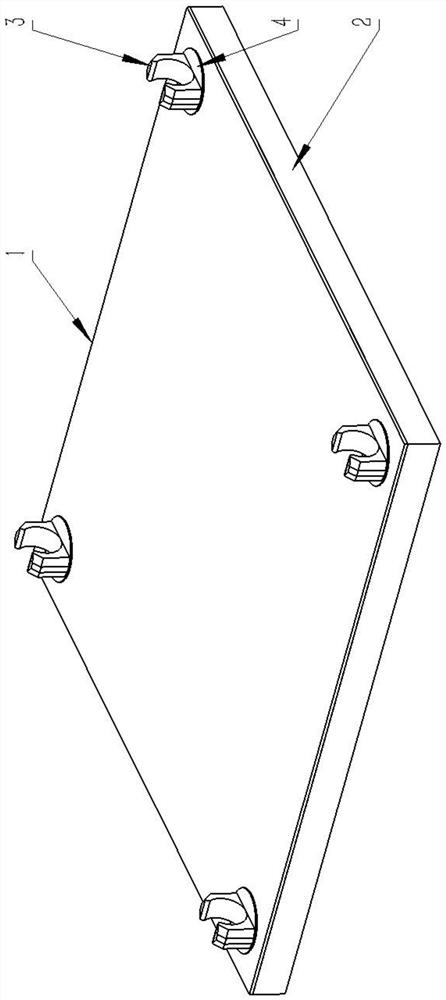

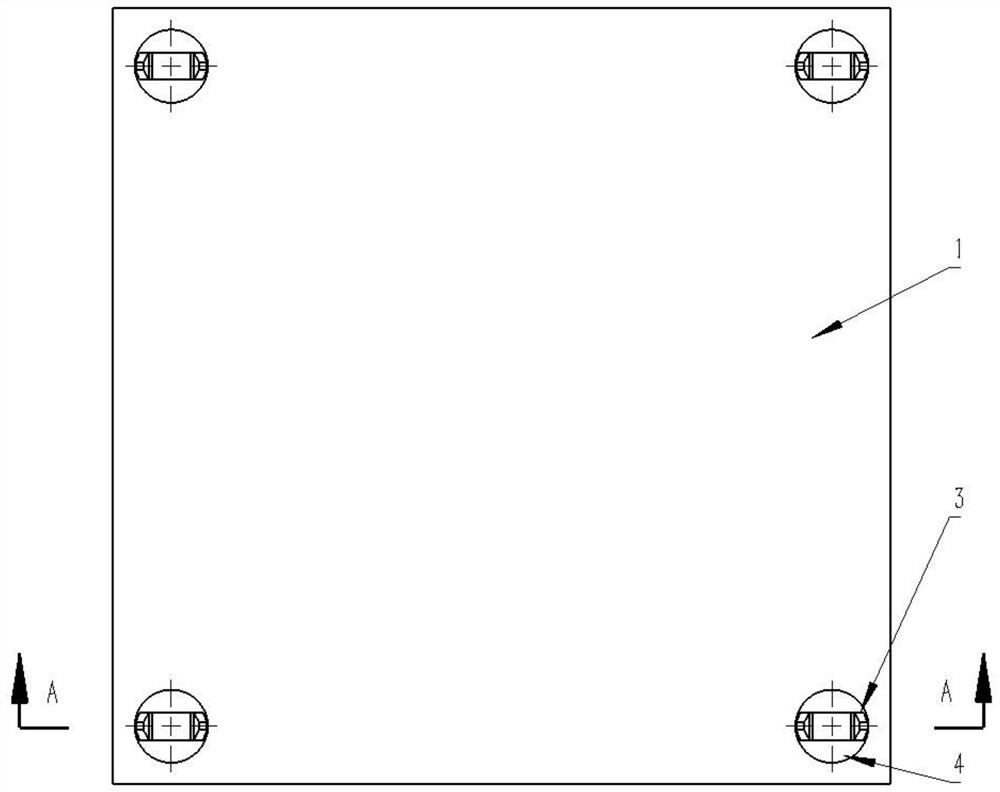

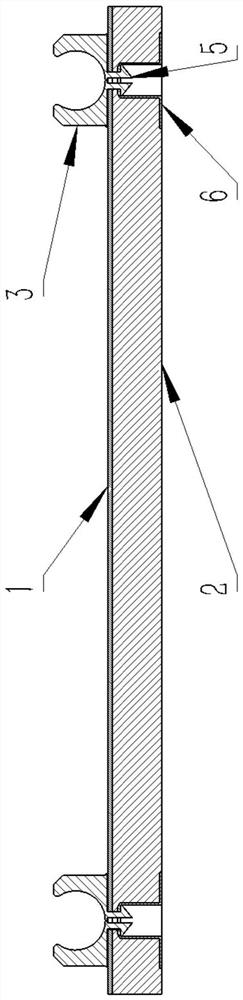

[0048] as attached figure 1 -Attached image 3 As shown, the present invention provides a modular structure for convenient laying of floor heating pipes, comprising a reflective film 1, a thermal insulation board 2 and a pipe clip 3. The thermal insulation board 2 is in the shape of a rectangular plate and the upper end surface is covered with a reflective film 1 to form a thermal insulation module , the four corners of the upper end of the heat preservation module are respectively embedded with pipe clips 3 with the opening facing upward.

[0049] Wherein, the part of the tube clip 3 abutting on the reflective film 1 is fixedly provided with a reinforced bottom plate 4, and the center of the lower end face of the reinforced bottom plate 4 is provided with an embedded block extending vertically downward. The block is a lower insert head 5 whose two lower ends are relatively expanded to form an inverted half-cone block structure and there is a gap between them.

[0050] Where...

Embodiment 2

[0052] On the basis of Example 1, as attached Figure 4 -Attached Figure 5 As shown, four steel mesh opening blocks 7 are evenly distributed at the edge of the upper end face of the reinforcing bottom plate 4, and the distance between the two steel mesh opening blocks 7 that are symmetrical about the center of the reinforcing bottom plate 4 is the same as the opposite two in the steel mesh. The spacing between the steel wires is equal, and the spacing between the adjacent pipe clips 3 of two adjacent modules is equal to an integer multiple of the mesh holes of the steel mesh, so that the steel mesh and each module structure are snapped together, which can improve the insulation board 2 The bearing strength can be improved, and the splicing strength between each module structure can be improved.

Embodiment 3

[0054] On the basis of the second embodiment, as attached Image 6 -Attached Figure 7 As shown, in order to simplify the structure of the embedded block embedded in the thermal insulation module, avoid penetrating the thermal insulation board 2 and enhance the thermal insulation effect, the joint cylinder 6 is cancelled, so that the two lower embedding heads 5 are directly embedded in the thermal insulation board 2 but do not penetrate the thermal insulation board 2. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com