Horizontal type closed strong-drying device for town waste

A technology of urban garbage and drying device, which is applied in the directions of garbage drying, drying gas layout, non-progressive dryer, etc. High problems, to achieve the effect of improving heat energy utilization efficiency, high dryness and high drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

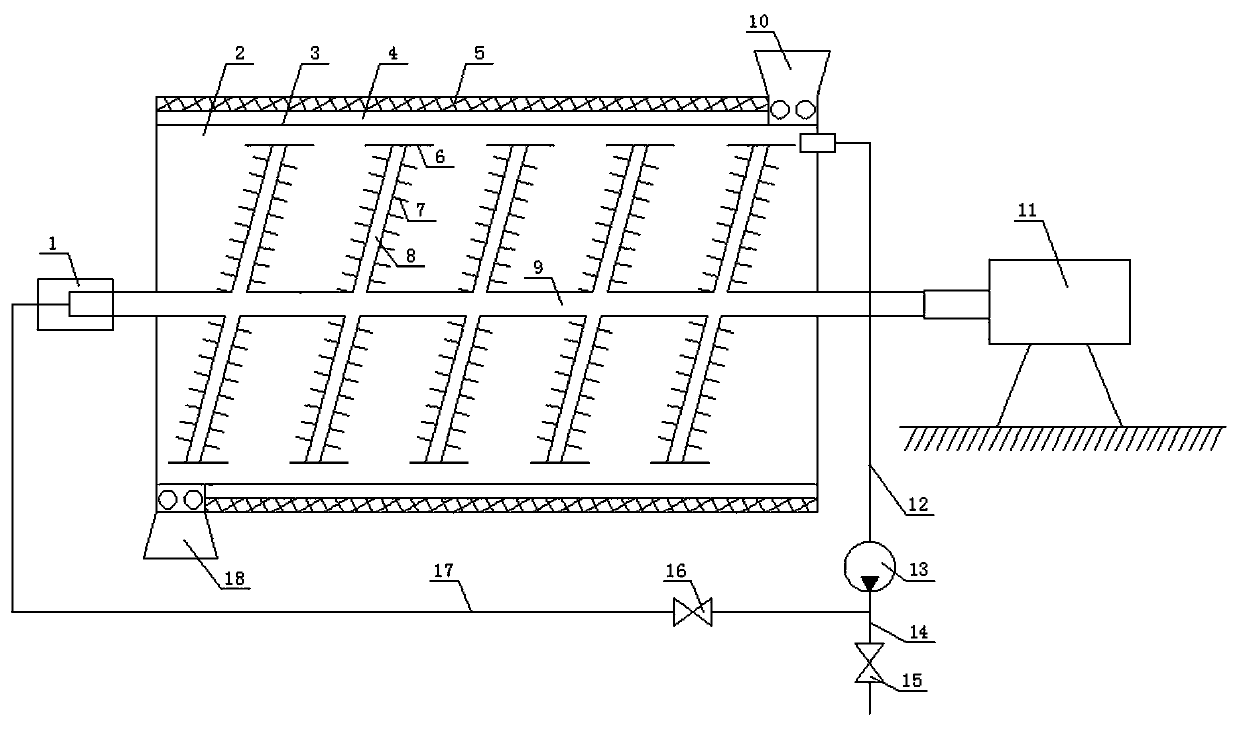

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 Shown, the present invention comprises airtight drying casing 2, is provided with airtight feeder 10 at the top of drying casing 2, is provided with airtight discharger 18 at the bottom of drying casing 2, in drying casing 2 simultaneously The shaft is rotatably connected with a hollow stirring shaft 9, and a plurality of hollow stirring rods 8 are evenly arranged on the stirring shaft 9, and the hollow cavity in the stirring rod 8 is connected with the hollow cavity in the stirring shaft 9. A plurality of air nozzles 7 are evenly arranged on the top, and both ends of the stirring shaft 9 are stretched out of the drying box 2, and one end of the stirring shaft 9 is connected with a motor 11 for driving the stirring shaft 9 to rotate, and the other end of the stirring shaft 9 One end is sealed and rotatably connected with an air valve 1, and a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com