Side part support variable amplitude mixing pile pressing integrated machine and construction method thereof

A construction method and integrated machine technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of low construction efficiency, reduced bearing capacity of pile composite foundation, large construction space, etc., to improve construction quality and efficiency , the effect of expanding the horizontal angle and improving the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Embodiments of the present invention will be described in detail below.

[0052] A construction method of a side-supported luffing-type pile-stirring integrated machine, the method comprising the following steps:

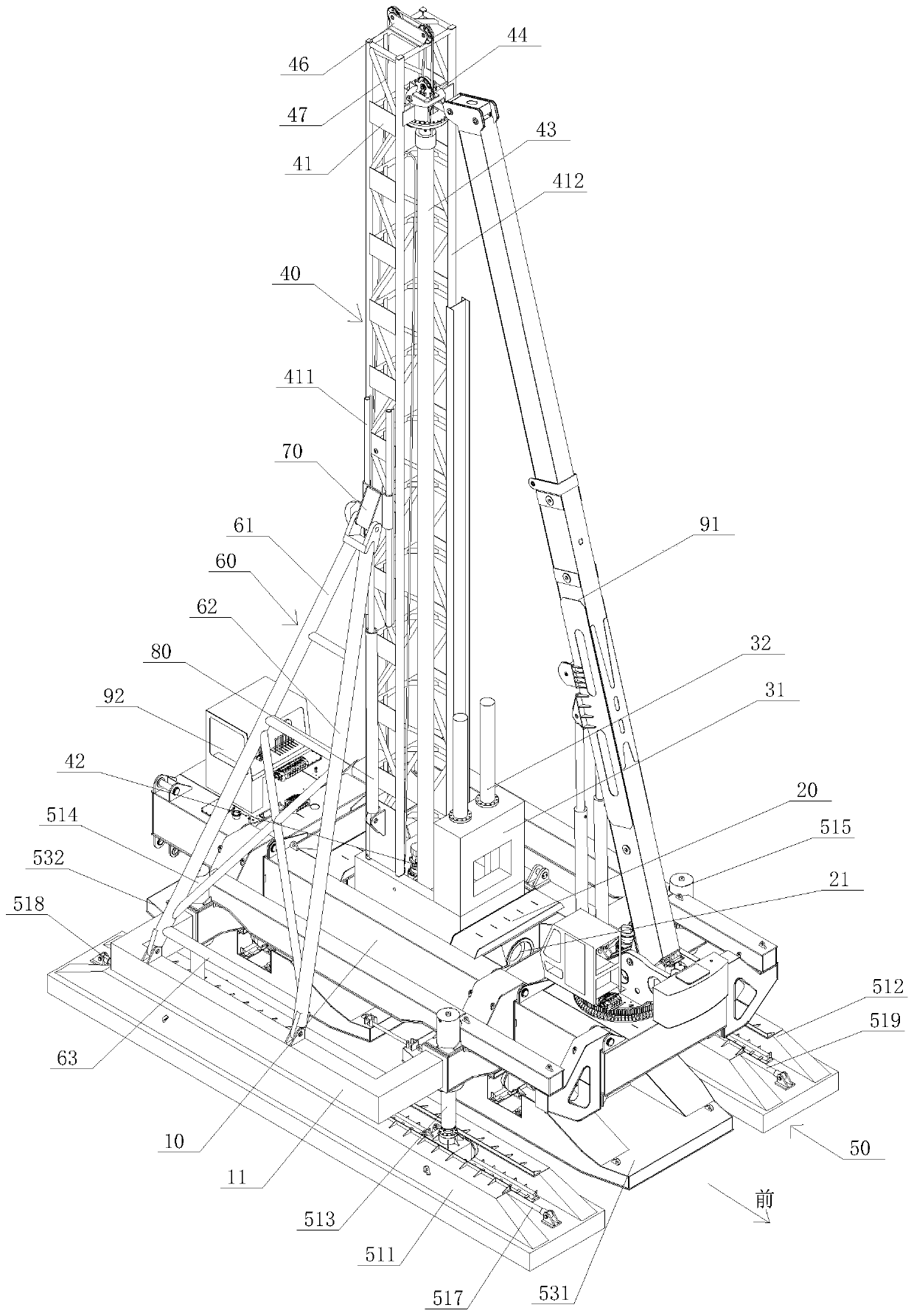

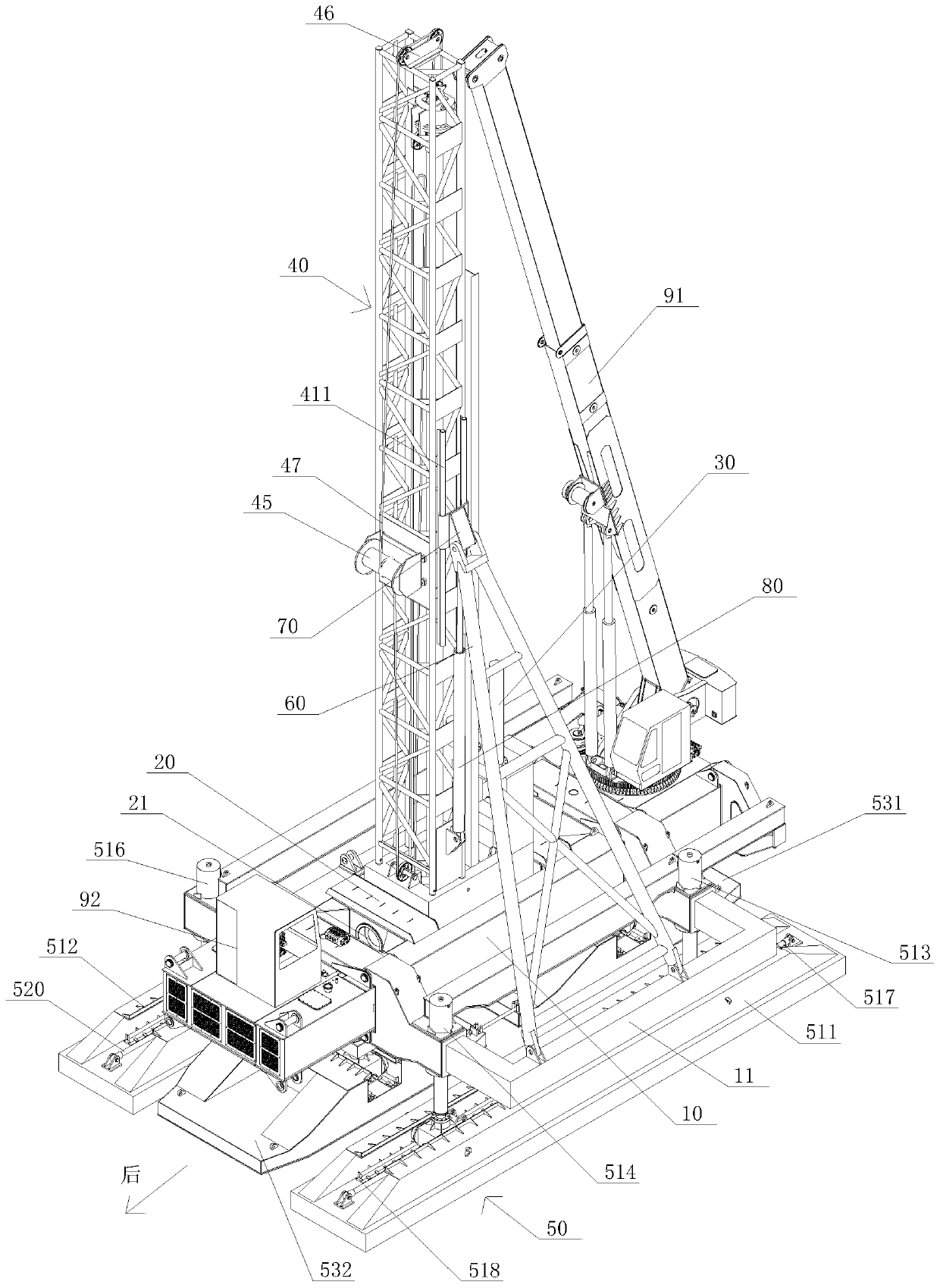

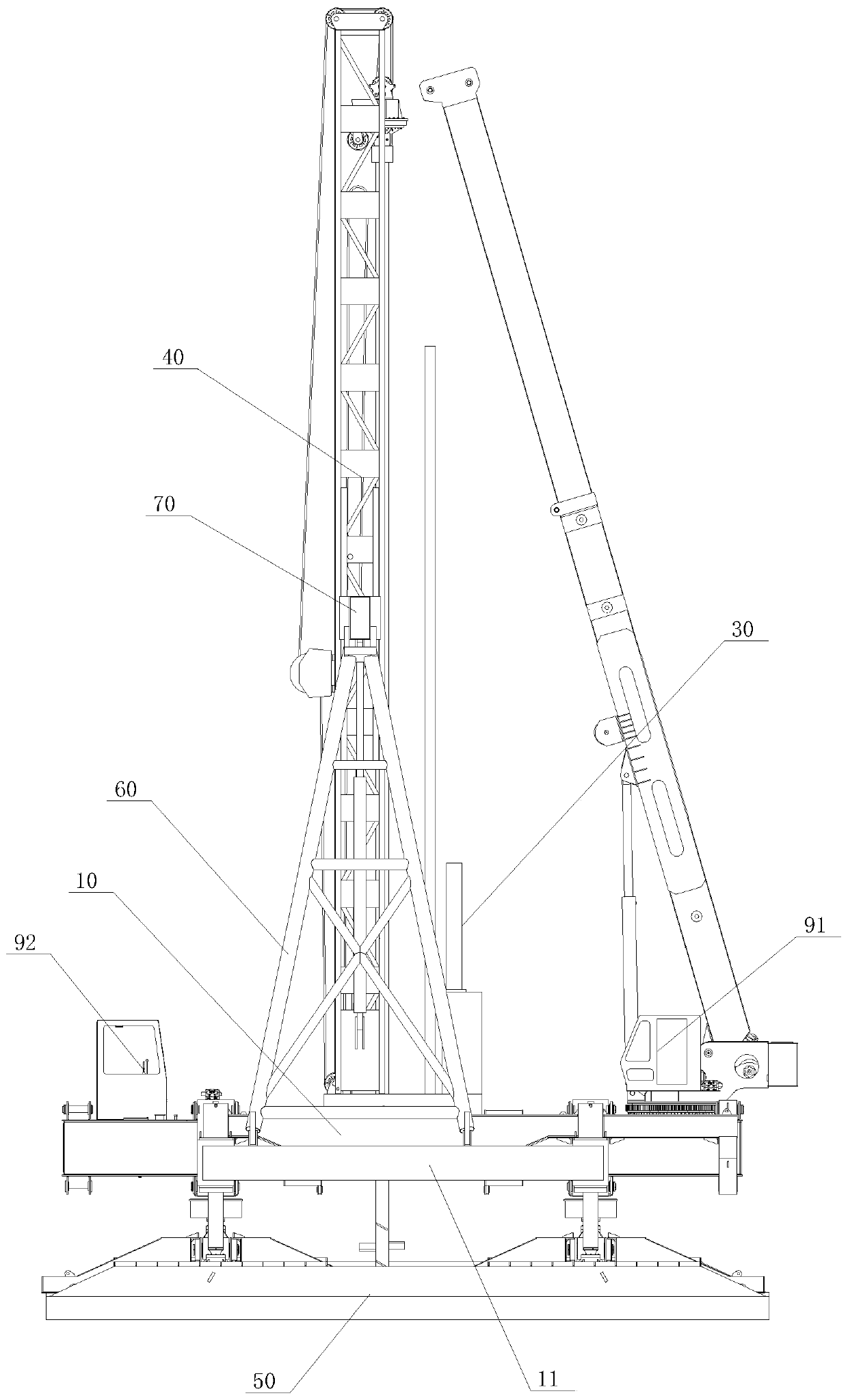

[0053] Step 1 pile driver is in place, its hydraulic pressure pile mechanism 30, stirring pile drilling mechanism 40 are installed on its host platform 10 rotating support 20 respectively; The side of host platform 10 is provided with supporting fixed beam 11 and support frame 60; The side support luffing type agitating and piling integrated machine is moved to the area to be constructed, and the drilling center of the side supporting luffing type agitating piling integrated machine is located directly above the pile position of the pile foundation to be constructed;

[0054] Step 2 Adjust the tilt angle, drive the sliding seat 70 to slide towards the upper or lower end of the tower 41, adjust the distance from the sliding seat 70 to the lower end of the towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com