Shaft part inner hole quenching and pressing tool

A shaft parts and inner hole technology, which is applied in the field of shaft parts inner hole quenching, pressing and positioning tooling, can solve the problems of increasing maintenance and repair difficulty, inconvenient use and maintenance, jamming, etc., so as to improve production efficiency and product quality. Quality, improved reliability and stability, and the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

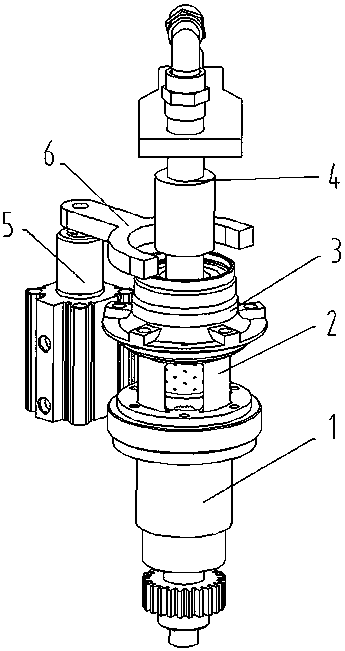

[0024] combine figure 1 As shown, a quenching and pressing positioning tool for the inner hole of shaft parts includes a spindle rotation assembly 1, a part positioning assembly 2, a rotating clamping assembly 5, a quenching coil and a spray device 4, a pressing arm and an auxiliary positioning assembly 6,

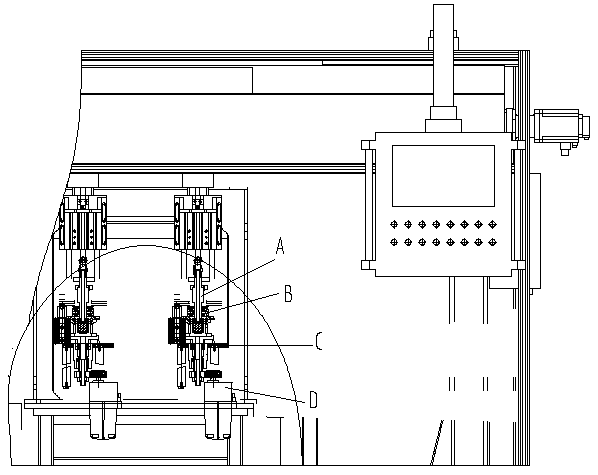

[0025] The tooling adopts a vertical structure, the axis of the parts is vertical, and it is installed on the work table of the machine tool as a whole. The lower part of the table is the spindle drive motor, which provides the rotating power of the parts;

[0026] The main shaft rotation assembly 1 meshes with the drive motor gear of the machine table to provide rotational power;

[0027] Part positioning assembly 2 is installed on the main shaft, on which adjustable axial positioning and radial positioning elements are installed. The positioning element makes the parts to be processed have the only correct position on the positioning pallet;

[0028] The quenching coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com