Cement-based electromagnetic developing composite material, preparation method and application thereof

A composite material and cement-based technology, which is applied in the field of detection and engineering geophysical prospecting, can solve the problems of insufficient detection depth and detection accuracy, poor detection effect, high dielectric constant, etc., achieve excellent electromagnetic performance, improve dielectric constant, dielectric constant, etc. Constant high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

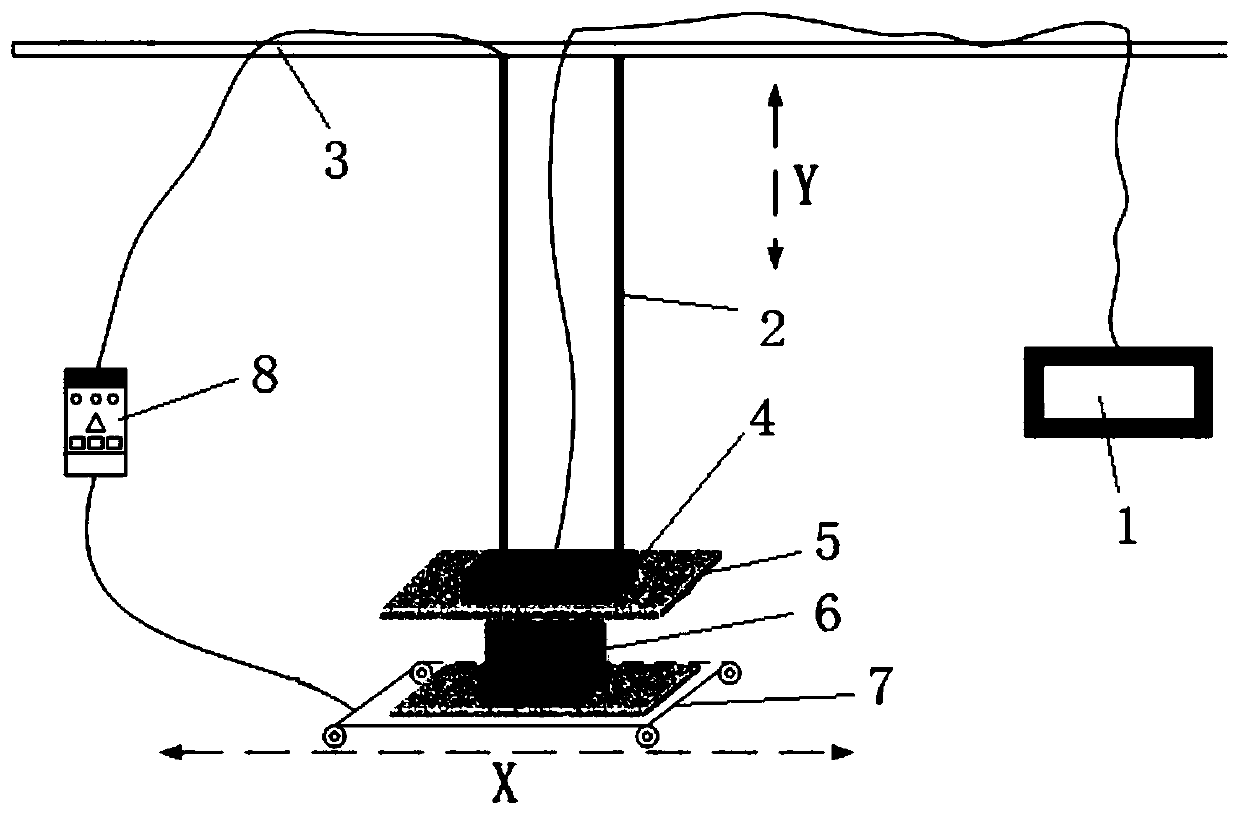

Image

Examples

Embodiment approach 1

[0038] The cement-based electromagnetic imaging composite material provided by this method, in parts by weight, the composite material consists of 100 parts by weight of Portland cement, 0.4 parts by weight of double-layer nano-graphene, nano-Fe 3 0 4 It consists of 0.4 parts by weight of powder and 0.1 parts by weight of sodium tripolyphosphate, wherein the water-cement ratio of Portland cement is 0.6.

[0039] The preparation method of the above-mentioned cement-based electromagnetic imaging composite material comprises the following steps:

[0040] Get 100 parts by weight of Portland cement, 0.4 parts by weight of nano-graphene, nano-Fe 3 0 40.4 parts by weight of powder and 0.1 parts by weight of graphene dispersant, under the action of a magnetic field with a magnetic field strength of 1.3T, 0.4 parts by weight of nano-graphene and 0.4 parts by weight of nano-Fe are respectively mixed into 100 parts by weight of Portland cement 3 0 4 The powder and 0.1 parts by weight...

Embodiment approach 2

[0042] The cement-based electromagnetic imaging composite material provided by this method is calculated in parts by weight, and the composite material consists of 100 parts by weight of Portland cement, 0.6 parts by weight of four-layer nano-graphene, nano-Fe 3 0 4 It consists of 0.6 parts by weight of powder and 0.5 parts by weight of sodium lauryl sulfate, wherein the water-cement ratio of Portland cement is 0.4.

[0043] The preparation method of the above-mentioned cement-based electromagnetic imaging composite material comprises the steps of: taking 100 parts by weight of Portland cement, 0.6 parts by weight of nano-graphene, and 0.6 parts by weight of nano-Fe 3 0 4 0.6 parts by weight of powder and 0.5 parts by weight of polyacrylamide, under the action of a magnetic field with a magnetic field strength of 1.7T, 0.6 parts by weight of nano-graphene and 0.6 parts by weight of nano-Fe are respectively mixed into 100 parts by weight of Portland cement 3 0 4 The powder a...

Embodiment approach 3

[0045] The cement-based electromagnetic imaging composite material provided by this method, in parts by weight, the composite material consists of 100 parts by weight of Portland cement, 0.5 parts by weight of single-layer nano-graphene, nano-Fe 3 0 4 0.5 parts by weight of powder and 0.3 parts by weight of graphene dispersant, wherein the water-cement ratio of Portland cement is 0.5.

[0046] The preparation method of the above-mentioned cement-based electromagnetic imaging composite material comprises the steps of: taking 100 parts by weight of Portland cement, 0.5 parts by weight of nano-graphene, and 0.5 parts by weight of nano-Fe 3 0 4 0.5 parts by weight of powder and 0.3 parts by weight of graphene dispersant, under the action of a magnetic field with a magnetic field strength of 1.5T, 0.5 parts by weight of nano-graphene and 0.5 parts by weight of nano-Fe are respectively mixed into 100 parts by weight of Portland cement 3 0 4 The powder and 0.3 parts by weight of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com