An environment-friendly landscape electric pole and its preparation method

An environmentally friendly, electric pole technology, applied in the field of electric pole production, can solve the problems of power supply and landscape harmony difficult to reach an agreement, and cables are difficult to enter the ground, etc., to achieve the effects of low cost, extended service life and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

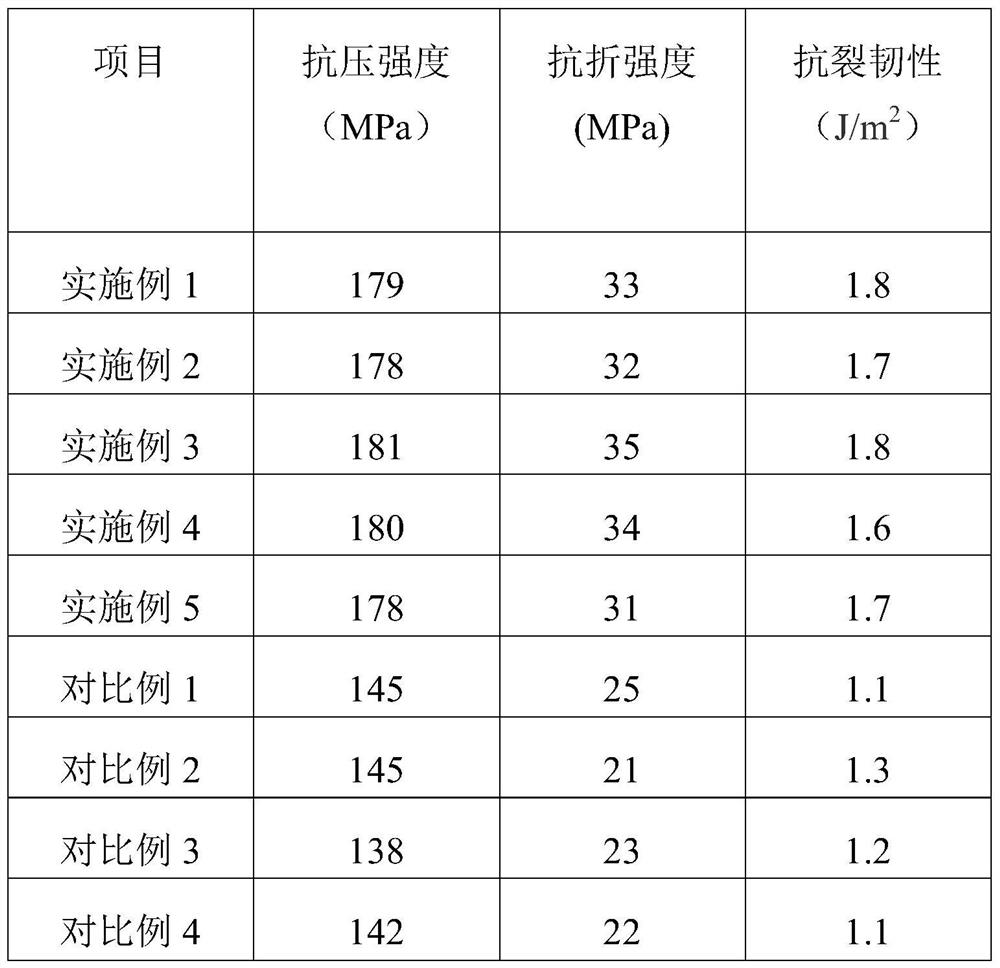

Examples

Embodiment 1

[0021] The preparation of each cubic concrete includes the following weight raw materials: 700kg of cement, 200kg of silica fume, 700kg of coarse sand, 300kg of medium sand, 150kg of fine sand, 90kg of gravel, 68 parts of steel fiber, 55kg of basalt fiber, 60kg of water reducing agent, 100kg of water, shells Powder 30kg, hornblende 28kg, glass powder 33kg, ebony powder 18kg.

Embodiment 2

[0023] The preparation of each cubic concrete includes the following weight raw materials: 800kg of cement, 300kg of silica fume, 803kg of coarse sand, 420kg of medium sand, 230kg of fine sand, 120kg of crushed stone, 83 parts of steel fiber, 86kg of basalt fiber, 80.5kg of water reducing agent, 320kg of water, Shell powder 68kg, hornblende 52kg, glass powder 50kg, ebony powder 43kg.

Embodiment 3

[0025] Prepare each cubic concrete including the following weight raw materials: 775.61kg of cement, 232.68kg of silica fume, 756.4kg of coarse sand, 380.33kg of medium sand, 174.05kg of fine sand, 114.3kg of gravel, 78.5 parts of steel fiber, 71.06kg of basalt fiber, water reducing Agent 70.5kg, water 124.4kg, shell powder 41.3kg, hornblende 32kg, glass powder 42.2kg, ebony powder 28.9kg.

[0026] Concrete preparation method: add 0.6mm coarse sand, 0.4mm medium sand, 0.2mm fine sand, and crushed stone into the mixer and stir for 2.5 minutes, then add cement and silica fume and dry mix for 3 minutes, add steel fiber and basalt fiber and stir After 6 minutes, mix half of the water and water reducer and pour it into the mixer for stirring. After 3 minutes, add the remaining water, shell powder, hornblende, glass powder, and ebony powder and stir for 6 minutes to obtain concrete;

[0027] The present invention also provides the preparation method of pole:

[0028] (1) Pour the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap