Method for preparing carbonate powder by smelting wastes by using stainless steel

A stainless steel and waste technology, which is applied in the field of carbonate powder preparation, can solve the problems of waste of resources, environmental pollution, metallurgical waste gas and waste acid environmental impact, and achieve the effect of increasing added value and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

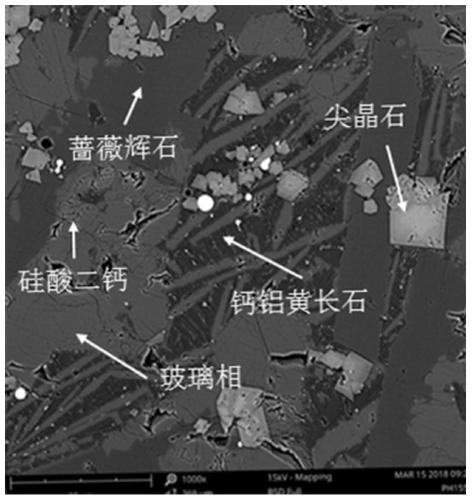

[0041] Step 1: During the slagging process of AOD refined stainless steel production, add MnO mineral phase reconstruction agent whose mass is 1% of stainless steel slag, and cool to 20°C after slagging.

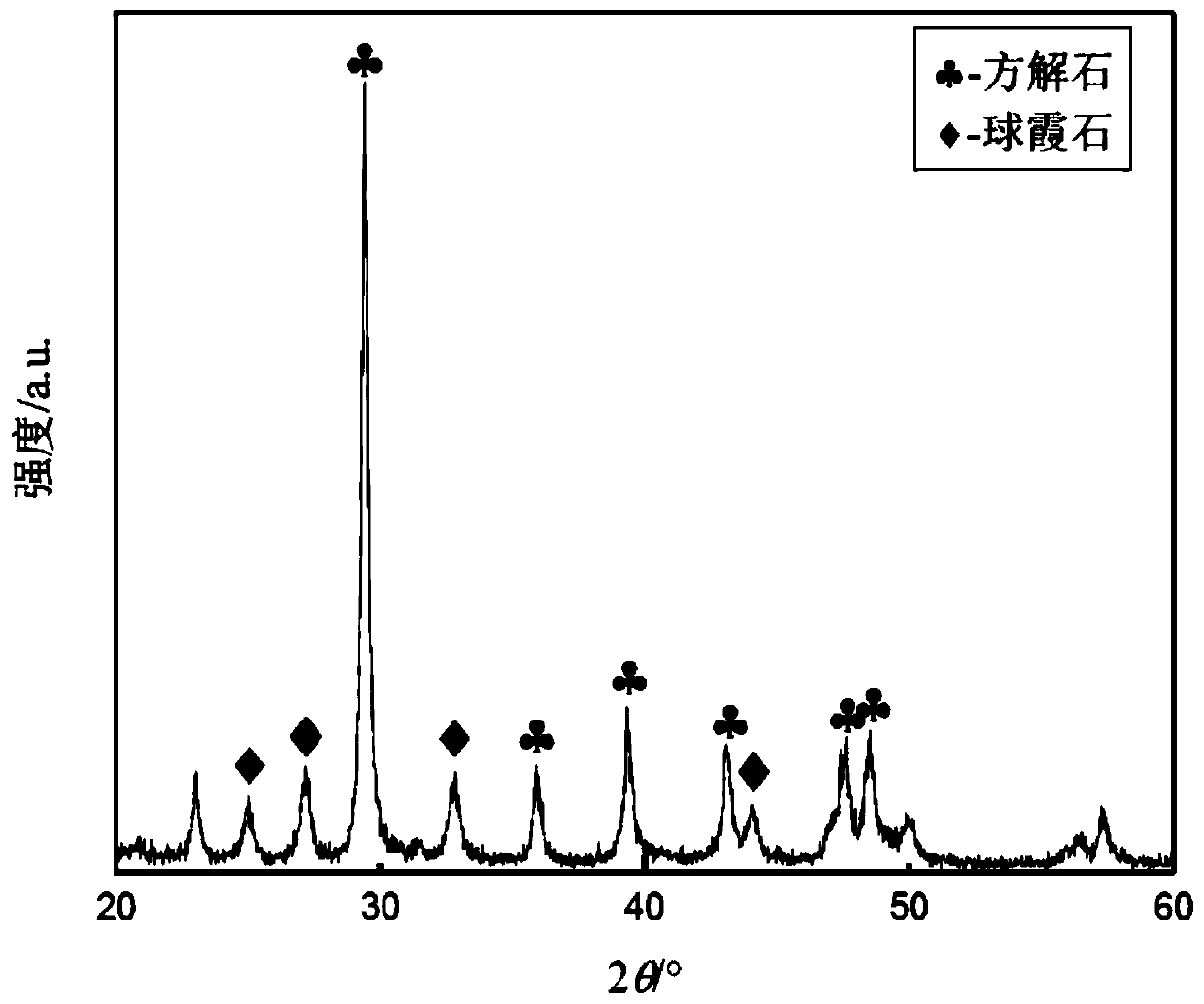

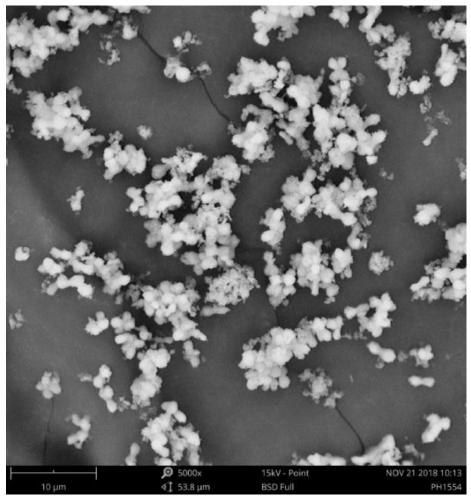

[0042] Step 2: Mechanically crush the stainless steel slag after mineral phase reconstruction, and select 300 g of stainless steel slag with a particle size of 1-5 mm. Use Rohm and Haas strong acid resin to absorb industrial waste acid to obtain HCl solution, add HCl to the obtained solution, adjust the pH of the solution to 2, and recycle the cleaned resin. Use 3000mL of the above-mentioned acid solution to pickle stainless steel slag with a particle size of 1-5mm in an ultrasonic oscillator. The specific acid leaching parameters are: ultrasonic oscillator power 100W, ultrasonic frequency 20KHz, temperature 20°C, leaching time 90min , stirring speed is 250rpm. After leaching, the filter residue was filtered to obtain solidified CO 2 initial solution.

[0043] Step 3: Add...

Embodiment 2

[0052] Step 1: During the slagging process of converter smelting stainless steel production, add MgO mineral phase reconstruction agent whose mass is 3% of stainless steel slag, and cool to 25° C. after slagging.

[0053] Step 2: Mechanically crush the stainless steel slag after mineral phase reconstruction, and select 300 g of stainless steel slag with a particle size of 9 mm. Adsorption of HCl+HNO by industrial waste acid with Rohm and Haas strong acid resin 3 solution, adding HCl to the resulting solution to adjust the pH of the solution to 4.5. The cleaned resin is recycled. Use 3500mL of the acid solution obtained above to carry out acid leaching of stainless steel slag with a particle size of 9mm in an ultrasonic oscillator. The speed is 410rpm. After leaching, the filter residue was filtered to obtain solidified CO 2 initial solution.

[0054] Step 3: Add KOH to the solution obtained in step 2, adjust the pH of the solution to 5.5, and add 17g of vinyl acetate-poly...

Embodiment 3

[0063] Step 1: During the slagging process of smelting stainless steel in electric furnace, add MnO ore phase reconstruction agent whose mass is 5% of stainless steel slag, and cool to 30°C after slagging.

[0064] Step 2: Mechanically crush the stainless steel slag after mineral phase reconstruction, and select 300g of stainless steel slag with a particle size of 10mm. Adsorption of industrial waste acid with Rohm and Haas strong acid resin to obtain HNO 3 +HF solution, adding HNO to the resulting solution 3 , adjust the pH of the solution to 4.8. The cleaned resin is recycled. Use 4000mL of the acid solution obtained above to carry out acid leaching of stainless steel slag with a particle size of 10mm in an ultrasonic oscillator. The speed is 480rpm. After leaching, the filter residue was filtered to obtain solidified CO 2 initial solution.

[0065] Step 3: Add NH to the solution obtained in Step 2 4 OH, adjust the pH of the solution to 5, and add 32 g of polyethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com