Device and method for preparing carbon nanotubes in batches

A carbon nanotube, batch technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as affecting preparation efficiency and production cost, ineffective collection, and inability to well solve carbon nanotube collection, etc. Achieve the effect of maintaining process stability, fast collection, and avoiding unstable airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

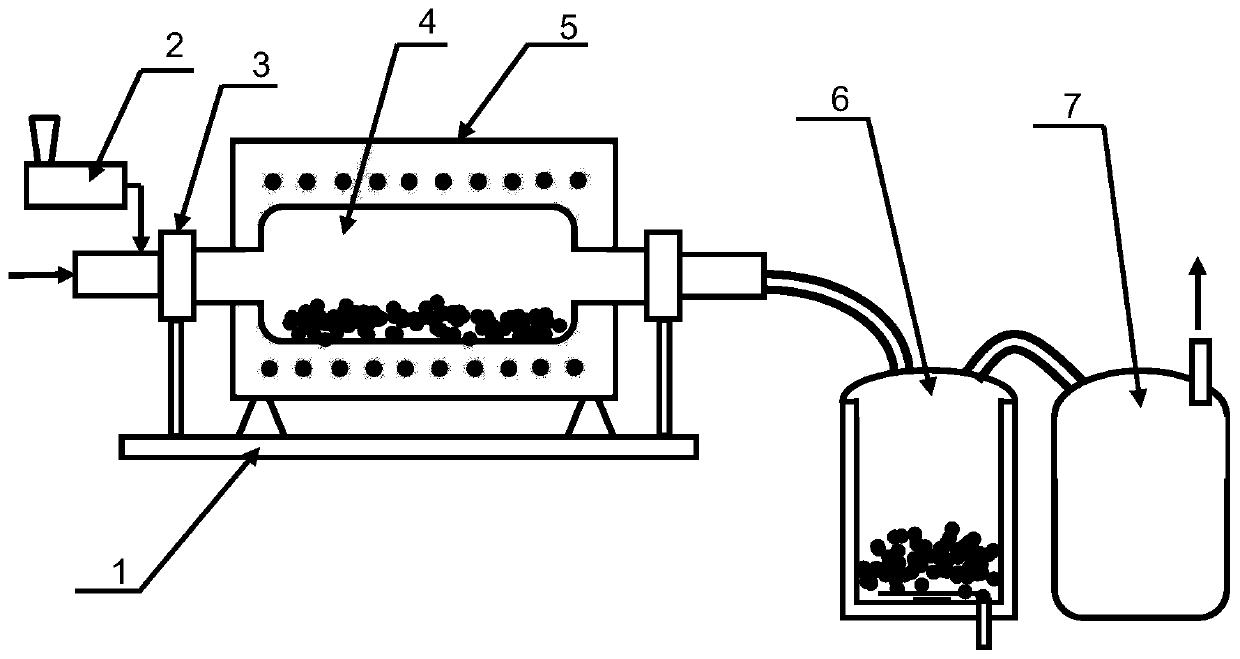

[0069] The device for preparing carbon nanotubes in batches is composed of a tiltable tubular rotary furnace, a solid feeder, a solid powder separator, and a powder collector, which are sealed and connected in series in sequence, and are opened and closed by valves. The solid feeder is a screw feeding mechanism with inert gas protection; the material of the furnace tube of the tiltable tube rotary furnace is quartz tube material, the diameter of the middle is larger than the diameter of both ends, and the diameter of both ends: the middle diameter = 1:1.5, The furnace tube can rotate continuously, and the whole furnace body can be inclined downward at an angle of 0-45 degrees to the tail of the furnace tube; the solid powder separator is a double-layer water-cooled stainless steel barrel with stirring blades at the bottom, and inert gas can be introduced from the bottom; The collector is the way of filtration and separation; in addition, there are auxiliary systems including va...

Embodiment 2

[0073] The device for preparing carbon nanotubes in batches is composed of a tiltable tubular rotary furnace, a solid feeder, a solid powder separator, and a powder collector, which are sealed and connected in series in sequence, and are opened and closed by valves. The solid feeder is a screw feeding mechanism with inert gas protection; the material of the furnace tube of the tiltable tube rotary furnace is quartz tube material, the diameter of the middle is larger than the diameter of both ends, and the diameter of both ends: the middle diameter = 1:1.1, The furnace tube can rotate continuously, and the whole furnace body can be inclined downward at an angle of 0-45 degrees to the tail of the furnace tube; the solid powder separator is a double-layer water-cooled stainless steel barrel with stirring blades at the bottom, and inert gas can be introduced from the bottom; The collector is a cyclone separation method; in addition, there are auxiliary systems including vacuum syst...

Embodiment 3

[0076] The device for preparing carbon nanotubes in batches is composed of a tiltable tubular rotary furnace, a solid feeder, a solid powder separator, and a powder collector, which are sealed and connected in series in sequence, and are opened and closed by valves. The solid feeder is a screw feeding mechanism with inert gas protection; the material of the furnace tube of the tiltable tube rotary furnace is quartz tube material, the diameter of the middle is larger than the diameter of both ends, and the diameter of both ends: the middle diameter = 1:5, The furnace tube can rotate continuously, and the whole furnace body can be inclined downward at an angle of 0-45 degrees to the tail of the furnace tube; the solid powder separator is a double-layer water-cooled stainless steel barrel with stirring blades at the bottom, and inert gas can be introduced from the bottom; The collector is the way of filtration and separation; in addition, there are auxiliary systems including vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com