Glass intermediate storage

A glass and storage technology, used in furnaces, charge control, lighting and heating equipment, etc., can solve the hidden safety hazards of glass storage, the inability to automatically classify the size of glass, etc., to save labor input, eliminate hidden safety hazards, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

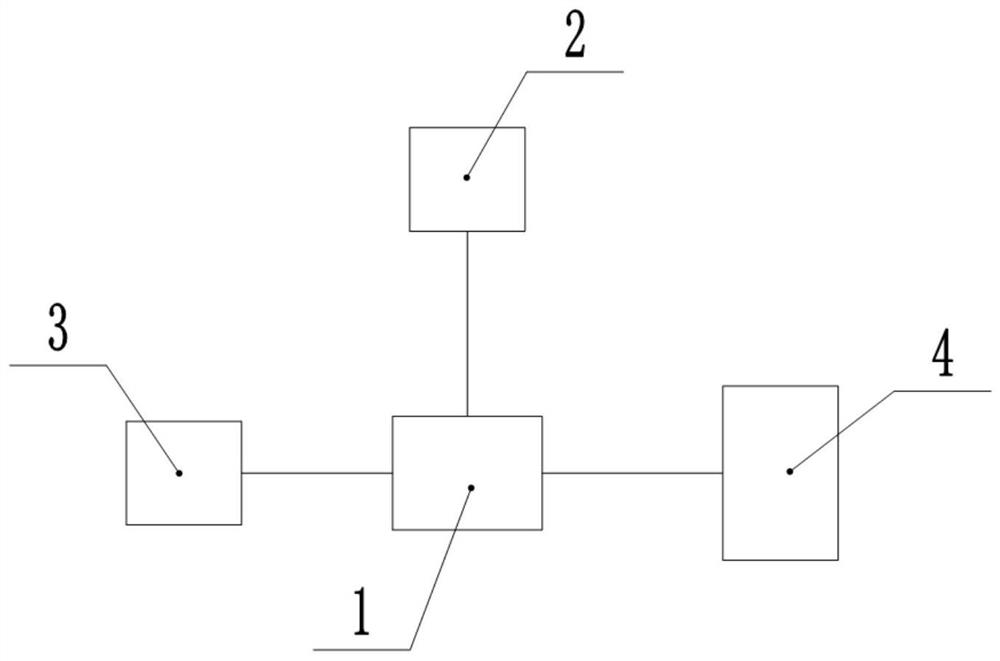

[0031] Embodiment one is basically as attached Figure 1 to Figure 5 Shown:

[0032] The glass intermediate storage includes a server 1, a scanning unit, a numbering unit and a fetching unit 4, and the scanning unit, the numbering unit, the fetching unit 4 and the server 1 are all connected by electrical signals. The server 1 is used to receive signals and issue instructions; the scanning unit is used to scan the glass entering the warehouse and record the size of the glass; the numbering unit is used to number the glasses of different sizes; in this embodiment, the server 1 For the scanning unit and the numbering unit, the server 1, the scanner 2 and the numbering unit 3 which are commonly used in the prior art are selected respectively, so as to realize the above-mentioned functions.

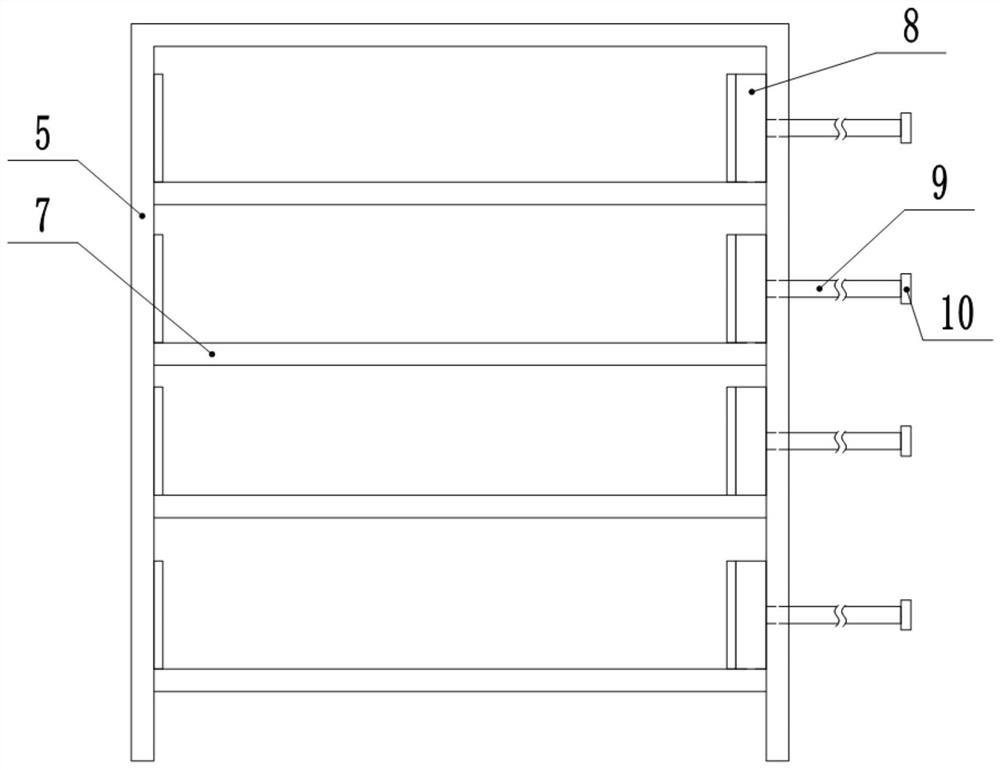

[0033] The fetching unit 4 includes a controller, a shelf for storing glass, and a pick-up device for taking glass. The controller is connected to the server 1 through electrical signals. The...

Embodiment 2

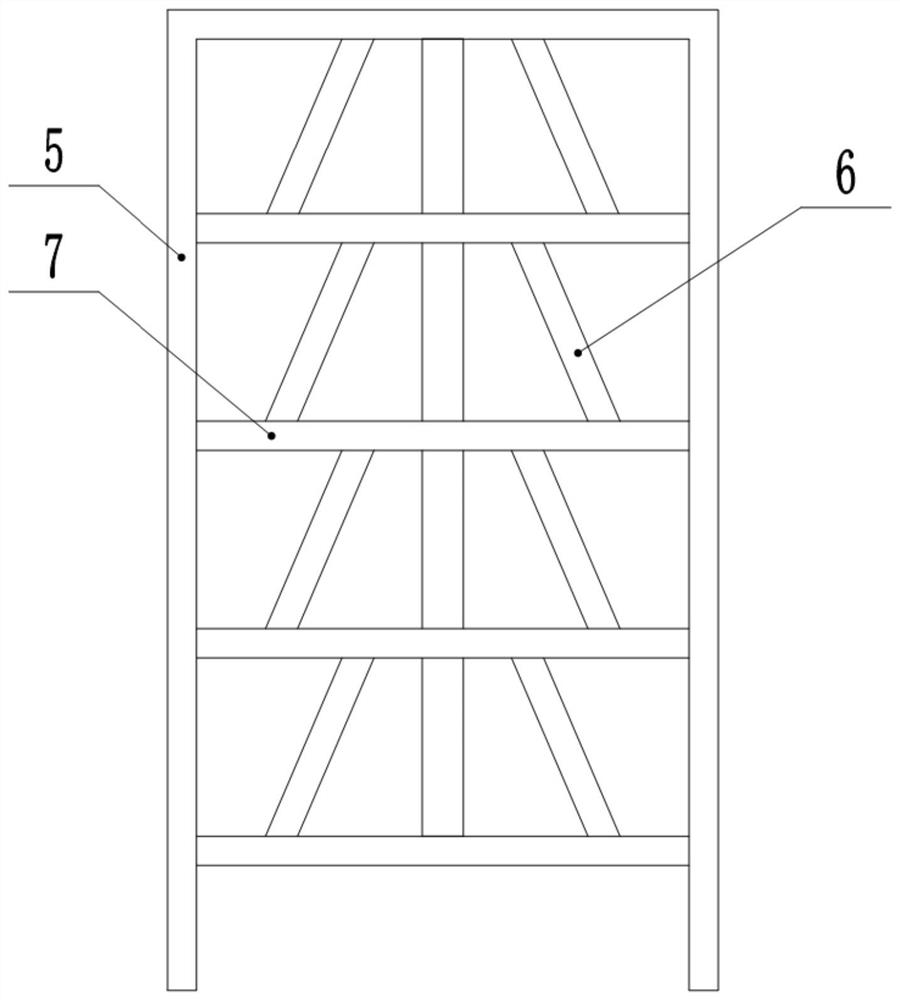

[0039] Embodiment two is basically as attached Figure 6 to Figure 8 Shown:

[0040] The difference between this embodiment and Embodiment 1 is that the dynamic and fixed mechanism includes a hand lever 11 and a connecting rod 12, the hand lever 11 is fixed on the front and rear sides of the first splint 8, and the upper end of the connecting rod 12 is hinged on the connecting rod 12. Above, the lower end of the connecting rod 12 is hinged with a positioning plate 13 abutting against the receiving plate 7 , and a torsion spring is fixedly connected to the hinge between the positioning plate 13 and the connecting rod 12 . In this embodiment, the receiving plate 7 is made of stainless steel or iron, and a magnet 14 is embedded and fixed on the side of the positioning plate 13 that abuts against the receiving plate 7 , that is, both the magnet 14 and the positioning plate 13 can abut against the receiving plate 7 . Anti-slip protrusions are integrally formed on the handle bar 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com