Novel beam and ram combined structure

A combined structure and crossbeam technology, applied in the field of machine tools, can solve problems such as the influence of machining accuracy, different degrees of wear, and offset of the center of gravity line, and achieve the effects of improving machining accuracy, eliminating bending moments, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

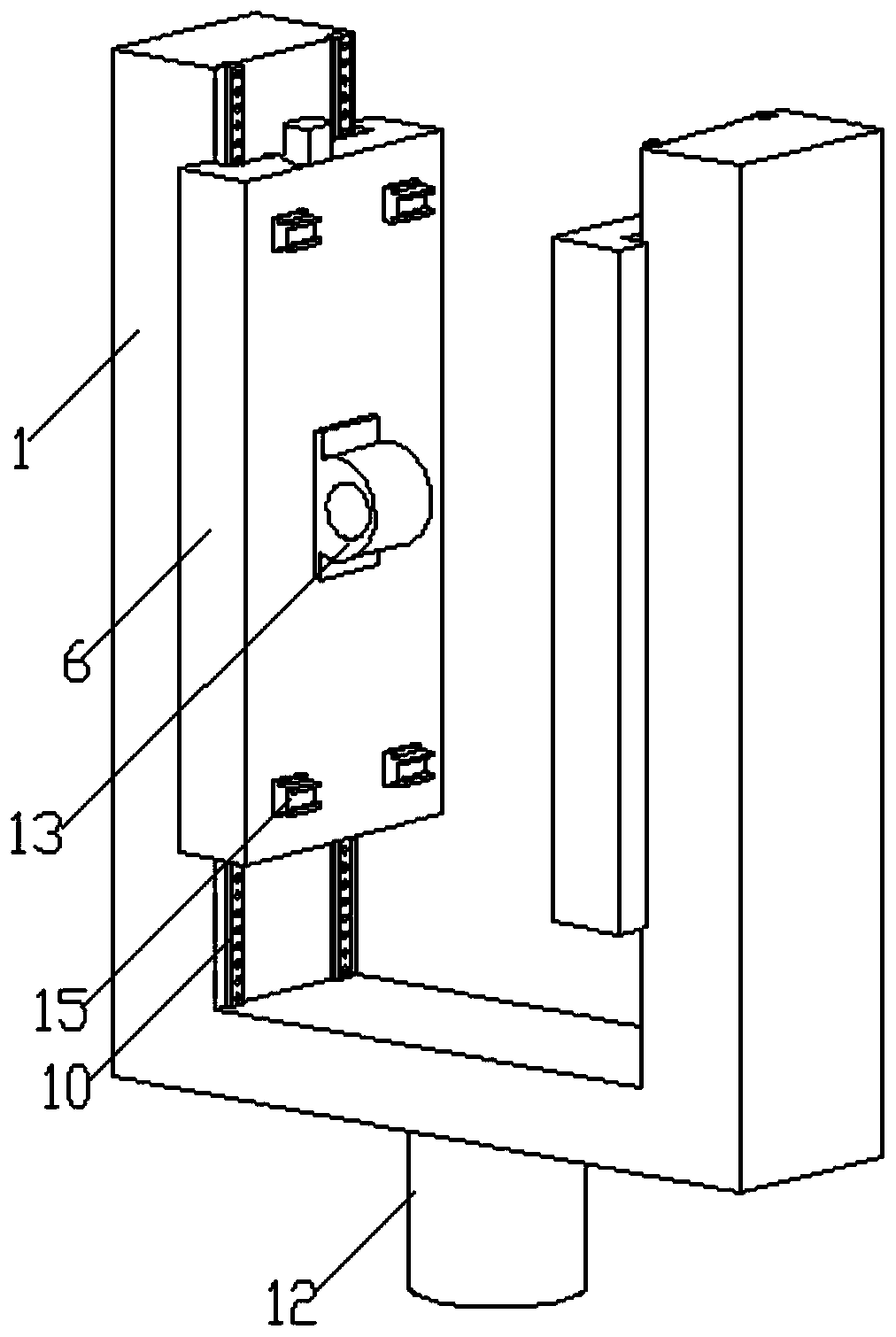

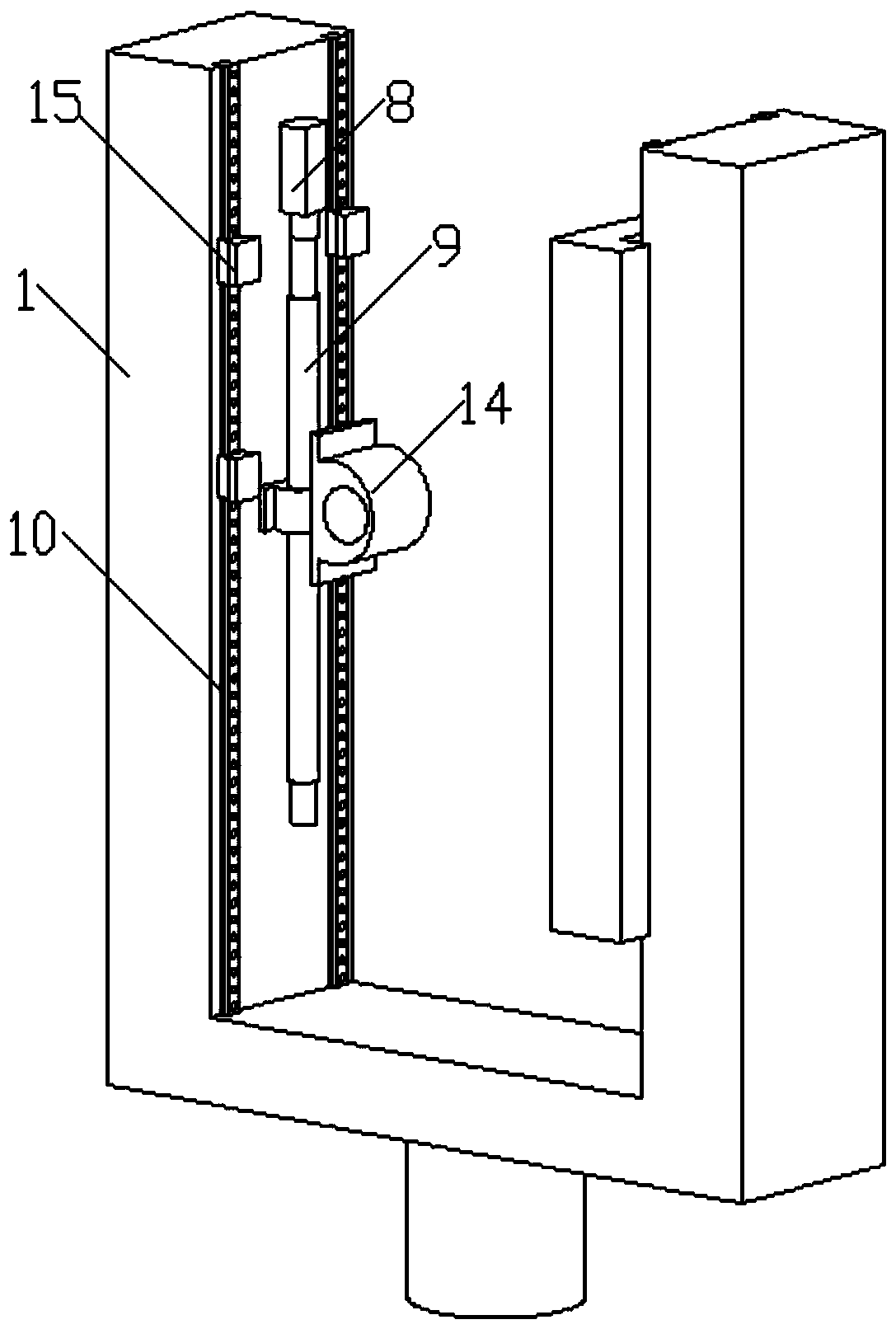

[0025] Such as figure 1 As shown, a novel crossbeam ram combination structure includes a U-shaped ram 1 and a crossbeam 2. The crossbeam 2 is laterally arranged in the groove of the U-shaped ram 1, and the concave of the U-shaped ram 1 The notch is upward, and the U-shaped ram 1 can slide laterally on the beam 2 through two lateral sliding mechanisms symmetrically arranged on both sides of the beam 2 , and along the The beam 2 moves vertically.

[0026] preferred, such as figure 1 and figure 2 As shown, the two sides of the beam 2 are provided with corresponding installation grooves 3 along the length direction, and the two lateral sliding mechanisms are arranged in the corresponding installation grooves 3 . The two described transverse sliding mechanisms have the same structure, and each described transverse sliding mechanism includes a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com