Dynamic visualization welding joint shearing stress fatigue test device and method

A fatigue test and shear stress technology, applied in the direction of using a stable shear force to test the strength of materials, measuring devices, and using repetitive force/pulse force to test the strength of materials, etc., can solve the problem that the cracking characteristics are difficult to observe and fatigue Cracking, inability to accurately record the cracking process and other problems, to achieve the effect of simple operation, accurate and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

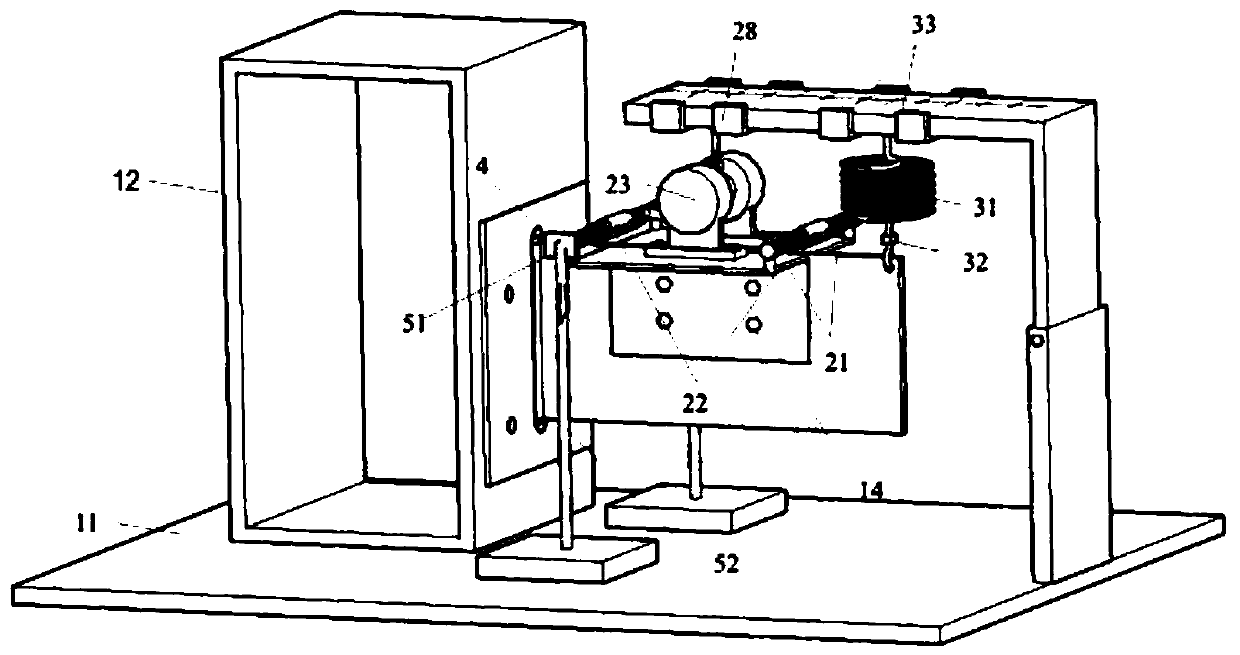

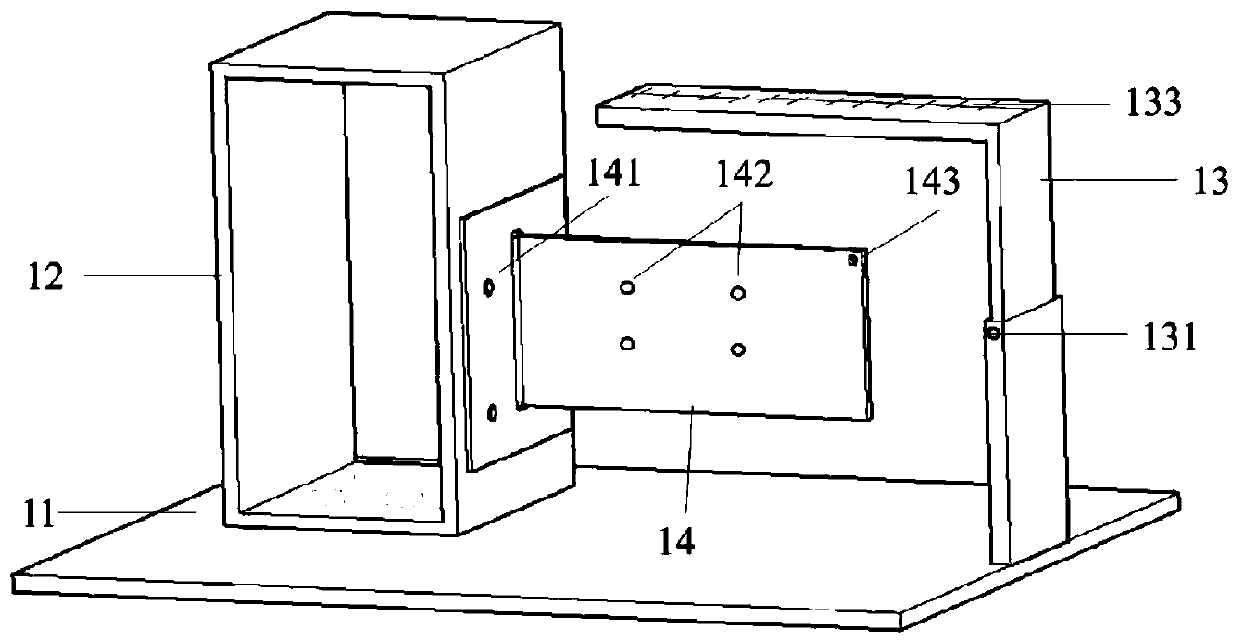

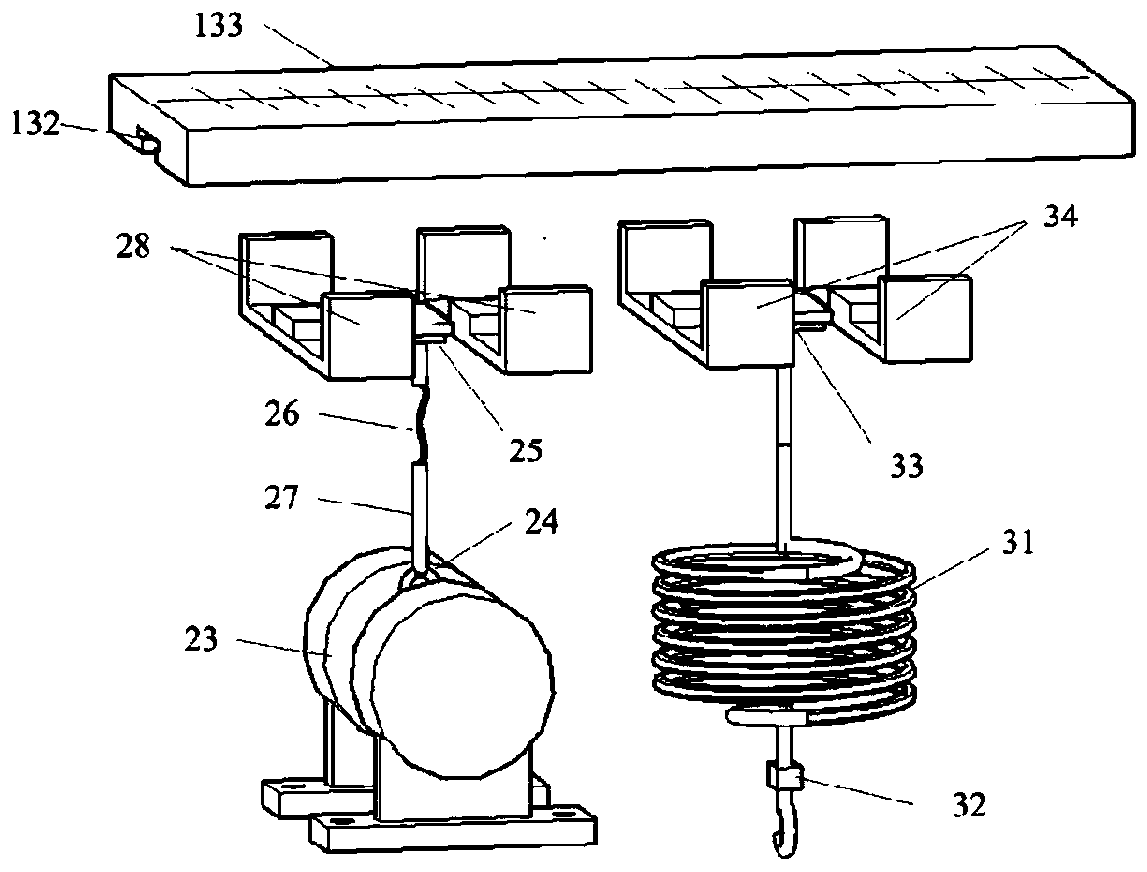

[0032] see Figure 1 to Figure 6 , of which, 1-rack system, 11-bottom plate, 12-rack, 13-mounting frame, 131-fastener, 132-chute, 133-scale line, 141-fixing bolt hole, 142-angle steel bolt hole , 143-spring bolt hole, 2-power system, 21-angle steel, 211-circle, 22-angle steel distance adjustment device, 221-threaded steel pipe, 222-rotary drum, 23-vibration motor, 24-hanging ring, 25-section One slider, 26-steel strand, 27-casing, 28-first slider fixer, 3-stress control system, 31-spring, 32-elasticity monitor, 33-second slider, 34-the first Two slider holders, 4-optical fiber inspection system, 5-visual monitoring system, 51-camera, 52-telescopic frame, 6-PLC integrated system, 61-equipment management module, 62-PLC system, 63-visual management module , 611-elasticity test system, 612-cyclic load test system, 613-fiber optic strain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com