Butt welding machine for steel structure engineering

A butt welding machine and steel structure technology, applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of poor welding quality and short service life of butt welding machines, and achieve convenient and efficient welding, long service life, and work high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

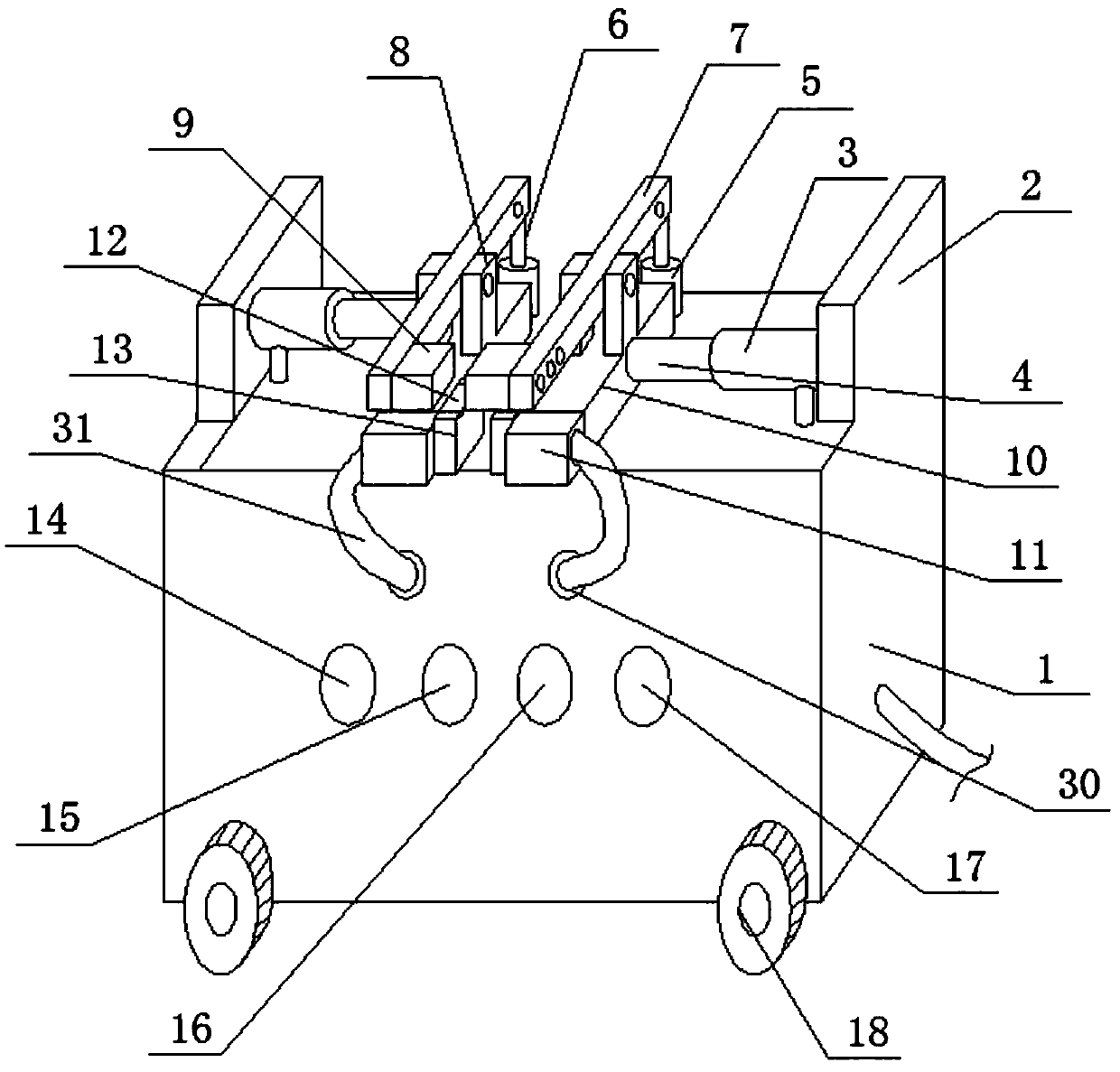

[0018] As a preferred embodiment of the present invention, the fixed plate 2, extrusion outer rod 3, extrusion cavity, extrusion inner rod 4, lifting outer rod 5 lifting chamber, lifting inner rod 6, lifting frame 7, pressing The quantity of block 9, sliding table 10, conducting table 11, dismounting block 12, clamping table 13, line opening 30 and line pipe 31 is 2.

[0019] As a preferred embodiment of the present invention, the number of the fixed frame 8 and the number of the rollers 18 are four.

[0020] As a preferred embodiment of the present invention, a connecting rotating shaft is arranged between the two rollers 18, and the number of connecting rotating shafts is two.

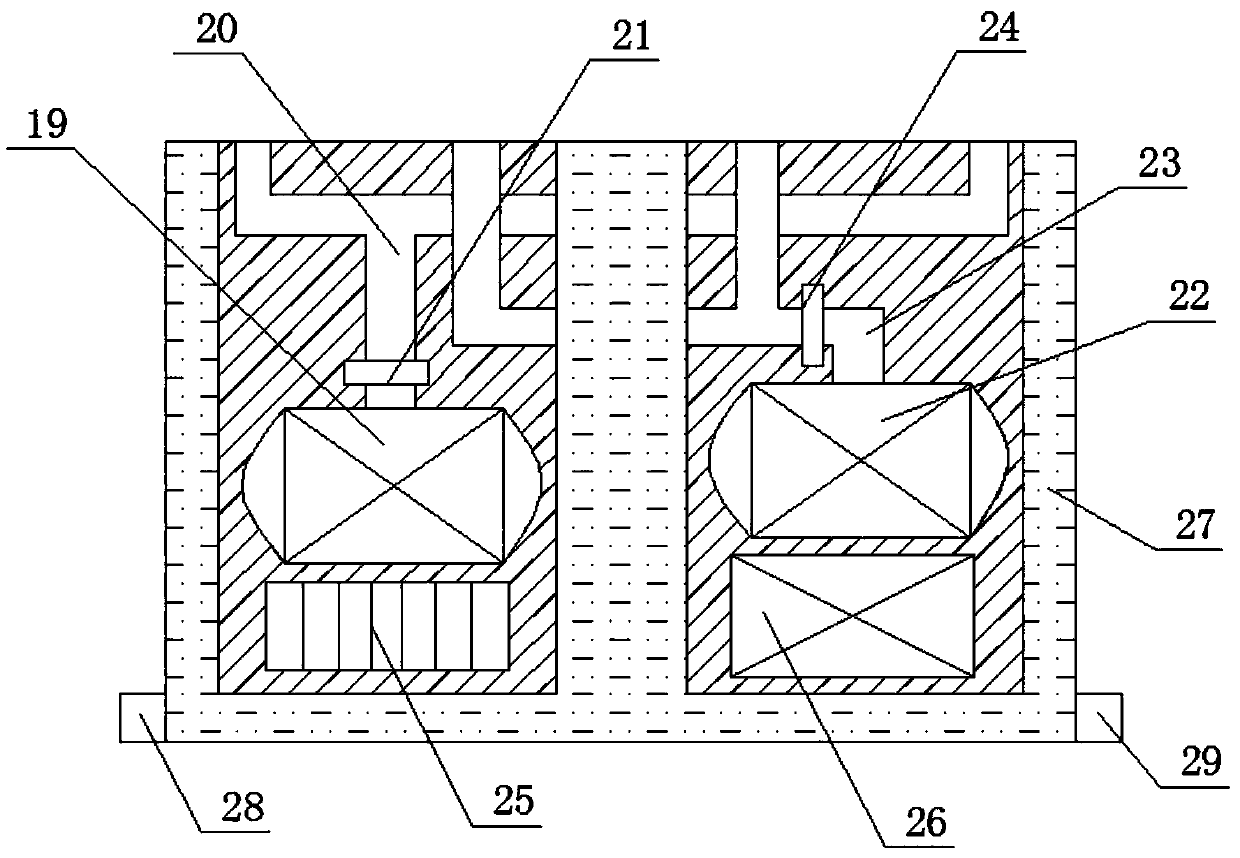

[0021] As a preferred embodiment of the present invention, both the water injection port 28 and the water outlet port 29 are provided with water blocking plugs.

[0022]Working principle: when using the butt welding machine for steel structure engineering, firstly, the storage battery 26 and the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com