All solid state lithium battery cathode interface modification method

An interface modification, lithium battery technology, applied in battery electrodes, negative electrodes, electrode manufacturing, etc., can solve problems such as generation of interface phases and poor wettability, and achieve the effect of buffering stress changes and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

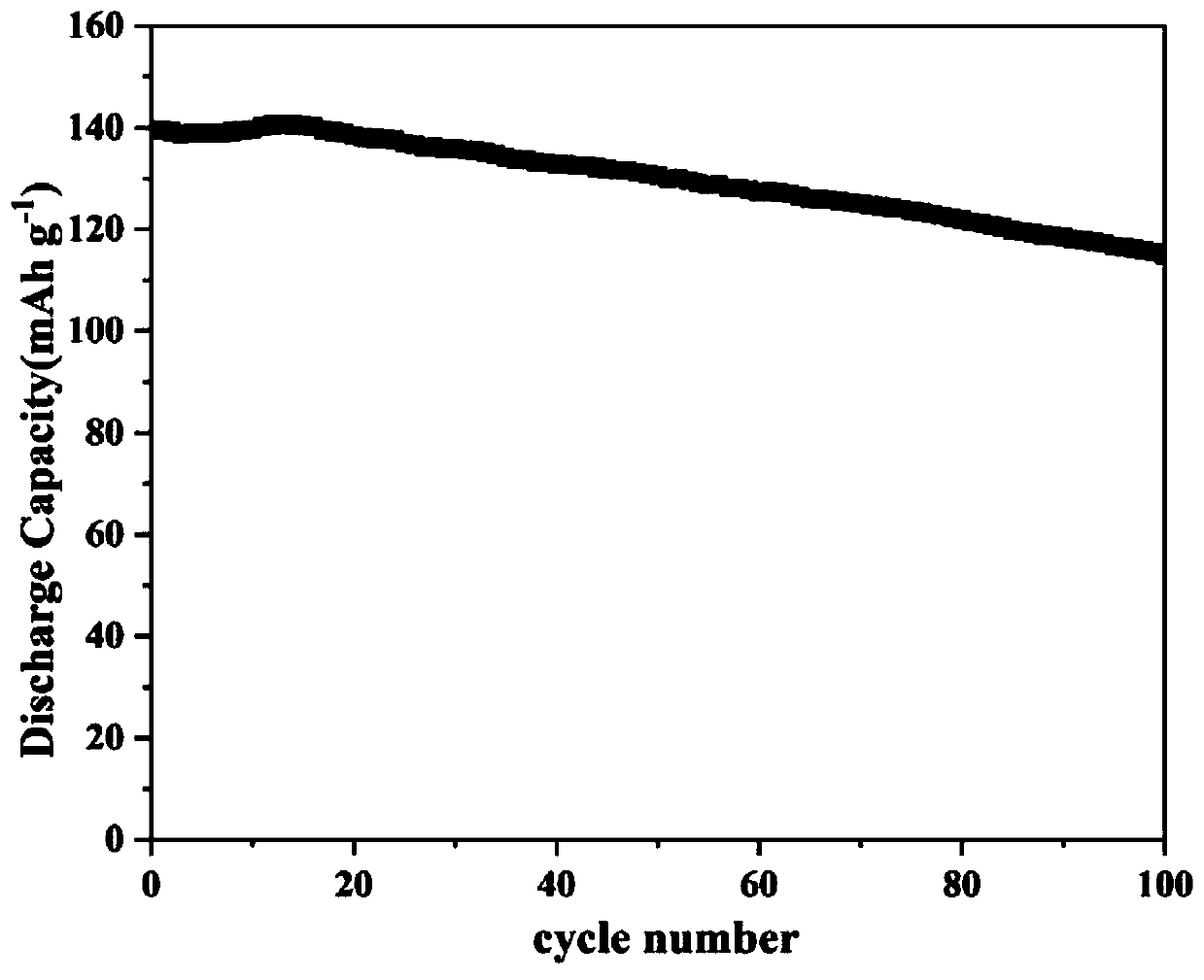

[0018] Using LiFeO 4 As the positive electrode material coated into a pole sheet, Li 1.3 al 0.3 Ti 1.7 (PO 4 ) 3 As the electrolyte sheet, metal lithium is used as the negative electrode. Weigh 1-butyl-2,3-dimethylimidazolium tetrafluoroborate, lithium salt and lithium nitrate according to 89.9:10:0.1, heat and stir at 50°C for 12 hours, apply the product dropwise on the electrolyte sheet, and statically After standing and solidifying, a modified layer with a thickness of 2 μm was obtained. According to the order of positive electrode-electrolyte-modified layer-negative electrode, it was assembled into a button battery for testing. Please refer to figure 1 , tested at 25°C, after 100 cycles of constant current discharge at 0.5C, it can still maintain 115mAh / g, showing good cycle stability.

Embodiment 2

[0020] Using LiCo 0.8 Ni 0.1 al 0.1 o 2 As the positive electrode material coated into pole piece, NASICON type Li 1.4 al 0.4 Ti 1.6 (PO 4 ) 3 As the electrolyte sheet, metal lithium is used as the negative electrode. Weigh 1-butyl-2,3-dimethylimidazolium tetrafluoroborate, lithium salt and lithium nitrate according to 79.9:20:3, heat and stir at 60°C for 24 hours, apply the product dropwise on the electrolyte sheet, and statically After standing and solidifying, a modified layer with a thickness of 20 μm was obtained. According to the order of positive electrode-electrolyte-modified layer-negative electrode, it was assembled into a button battery for testing. Tested at 25°C, after 100 cycles of constant current discharge at 0.5C, it can still maintain 123mAh / g, showing good cycle stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com