Battery module heat conduction structure and gluing method

A battery module and heat conduction technology, applied in battery pack parts, secondary batteries, structural parts, etc., can solve the problems of difficult heat dissipation, poor heat dissipation effect, and high cell temperature, so as to facilitate heat conduction and improve the overall Robustness, the effect of reducing heat transfer paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

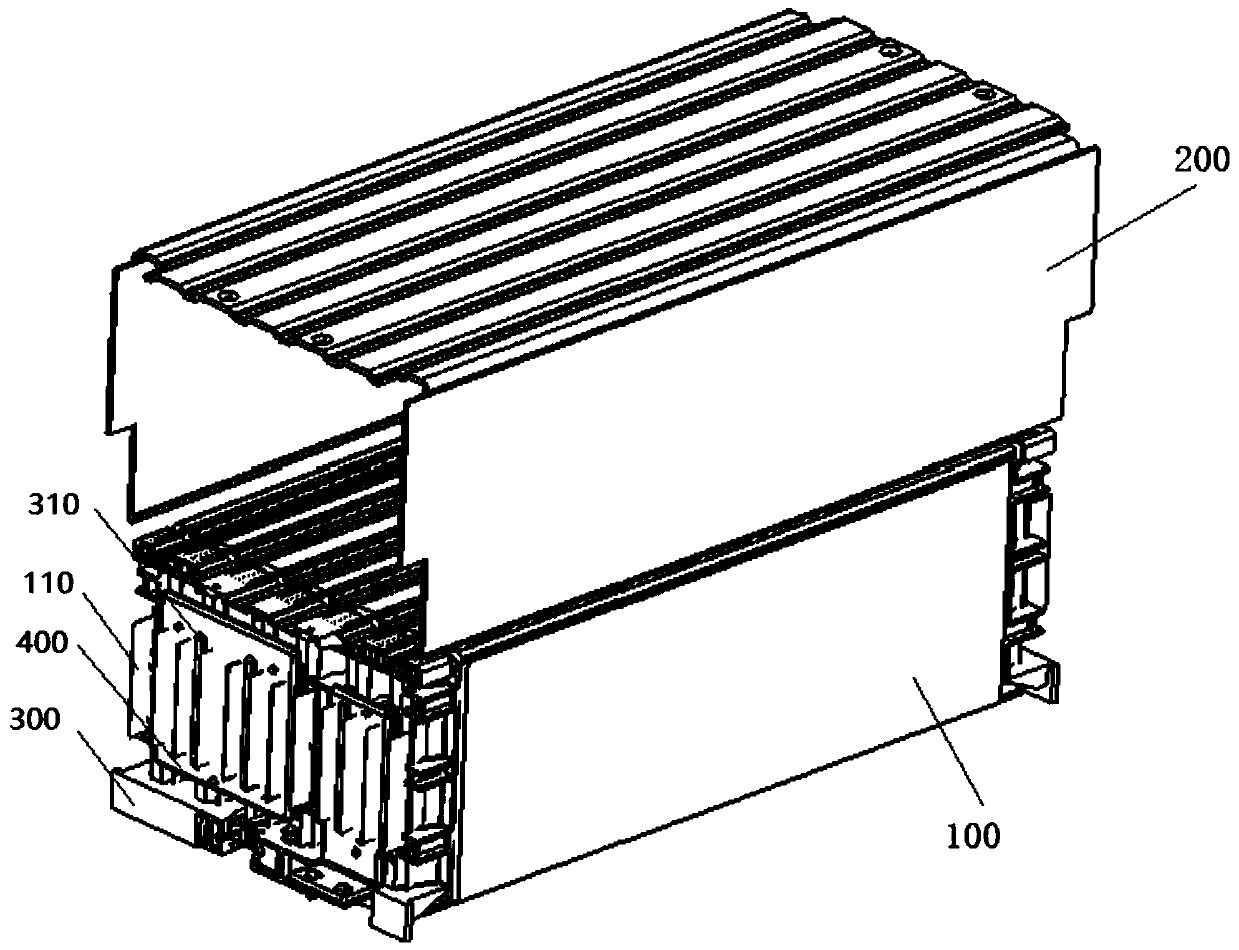

[0040] see figure 1 , before the cell assembly 100 is inserted into the U-shaped shell 200, the cell assembly is turned over 180 degrees, and the top of the cell assembly 100 after turning over is coated with thermally conductive glue, so that the filling condition of the thermally conductive glue can be visually observed, and after the thermally conductive glue is applied , and then turn the U-shaped shell 180 degrees, and then place the U-shaped shell on the top of the cell assembly, pull the U-shaped shell 200 to a certain extent with an external force, and push the cell assembly 100 into the U-shaped shell 200 with an external force , the protruding part of the U-shaped shell 200 is in contact with the glued area first, and the excess glue and air are discharged outwards to ensure the heat conduction between the battery cell assembly 100 and the U-shaped shell 200. After the thermally conductive glue is cured, the battery cell assembly 100 Can be firmly fixed in the design...

Embodiment 2

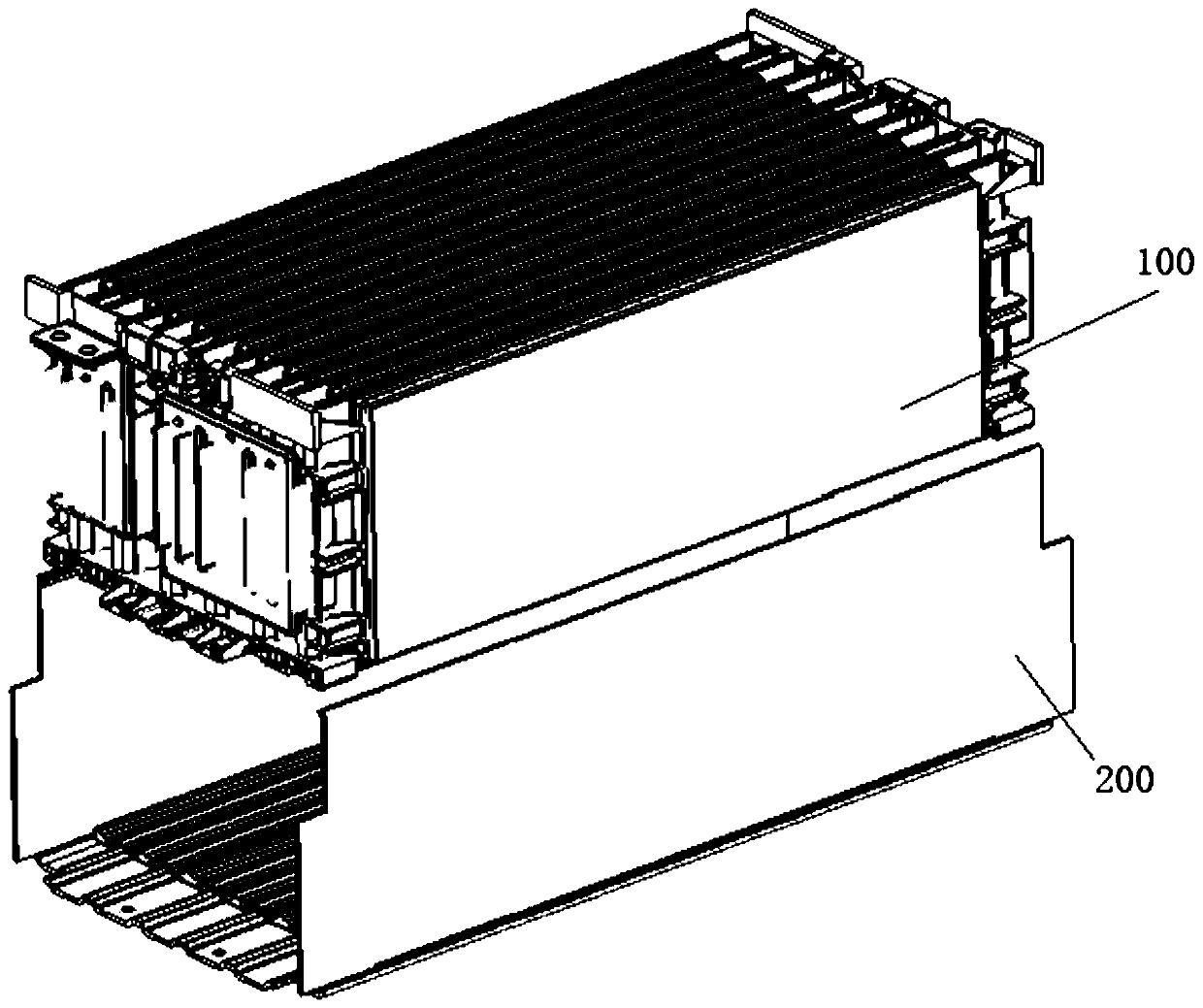

[0042] see figure 2 , put the U-shaped shell 200 in the glue coating station, use a glue applicator to coat the bottom of the U-shaped shell 200 with a certain thickness of heat-conducting glue, and then use external force to pull the U-shaped shell 200 to a certain extent, and push the cell assembly 100 to the U-shaped In the shell 200, the battery cell assembly 100 and the U-shaped shell 200 are fully squeezed, one end of the battery cell assembly 100 first contacts the glue coating area, and then the other side is contacted and pressed, and the heat-conducting glue is filled to the U-shaped area under the action of extrusion force. In the gap between the U-shaped shells 200, after the thermally conductive adhesive is cured, the U-shaped shell 200 is firmly fixed at a designated position.

[0043] The above gluing method can be determined according to actual needs. If the folded edge of the battery cell is close to the body of the battery cell, embodiment 1 or embodiment 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com