Method for measuring surface membrane penetration amount of sand-gravel material triaxial sample by digital image technology

A triaxial sample and digital image technology, applied in the direction of measuring device, using stable tension/pressure to test material strength, analyzing materials, etc., can solve the problem that it is impossible to simulate the change of embedded amount, it is difficult to ensure the accuracy of test results, and the operation Difficulty and other issues, to achieve good promotion value, ensure accuracy, and low laboratory environment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The above-mentioned measurement method will be described in detail below in conjunction with examples.

[0034] The invention relates to a method for measuring the embedding amount of the surface film of a triaxial sample of sand and gravel by digital image technology, comprising the following steps:

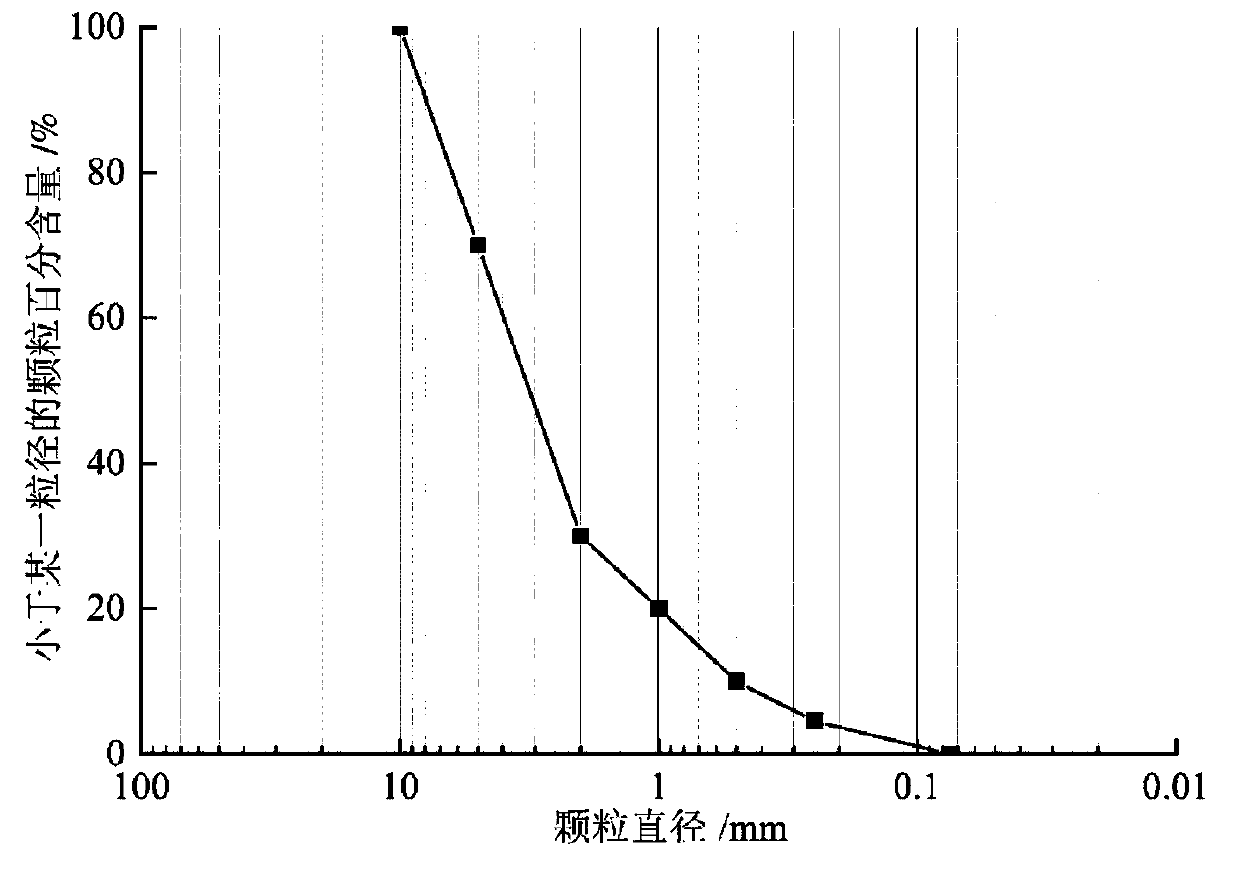

[0035] (a) Using a new type of medium-sized visual triaxial test equipment, prepare a saturated triaxial sample of sand and gravel material according to the conventional test method in the "Soil Engineering Test Regulations"-procedure number SL237-1999. The sample is a cylinder with a height of 200mm and a diameter of 100mm. The control index of sample preparation is relative compactness. In this test, the gradation of the gravel used is shown in figure 1 , the relative compactness of the sample preparation control index is 50%. The rubber film used in the installation process of the triaxial sample has undergone speckle treatment. The treatment method is to randomly sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com